Bidirectional direct-current motor driving integrated circuit

A technology of motor drive and integrated circuit, applied in the direction of single DC motor starter, motor generator/starter, sustainable manufacturing/processing, etc., can solve the problems of complex circuit, simple function, large volume, etc., and achieve circuit structure Simple, wide-ranging application and multi-functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0035] The invention provides a bidirectional DC motor driving integrated circuit.

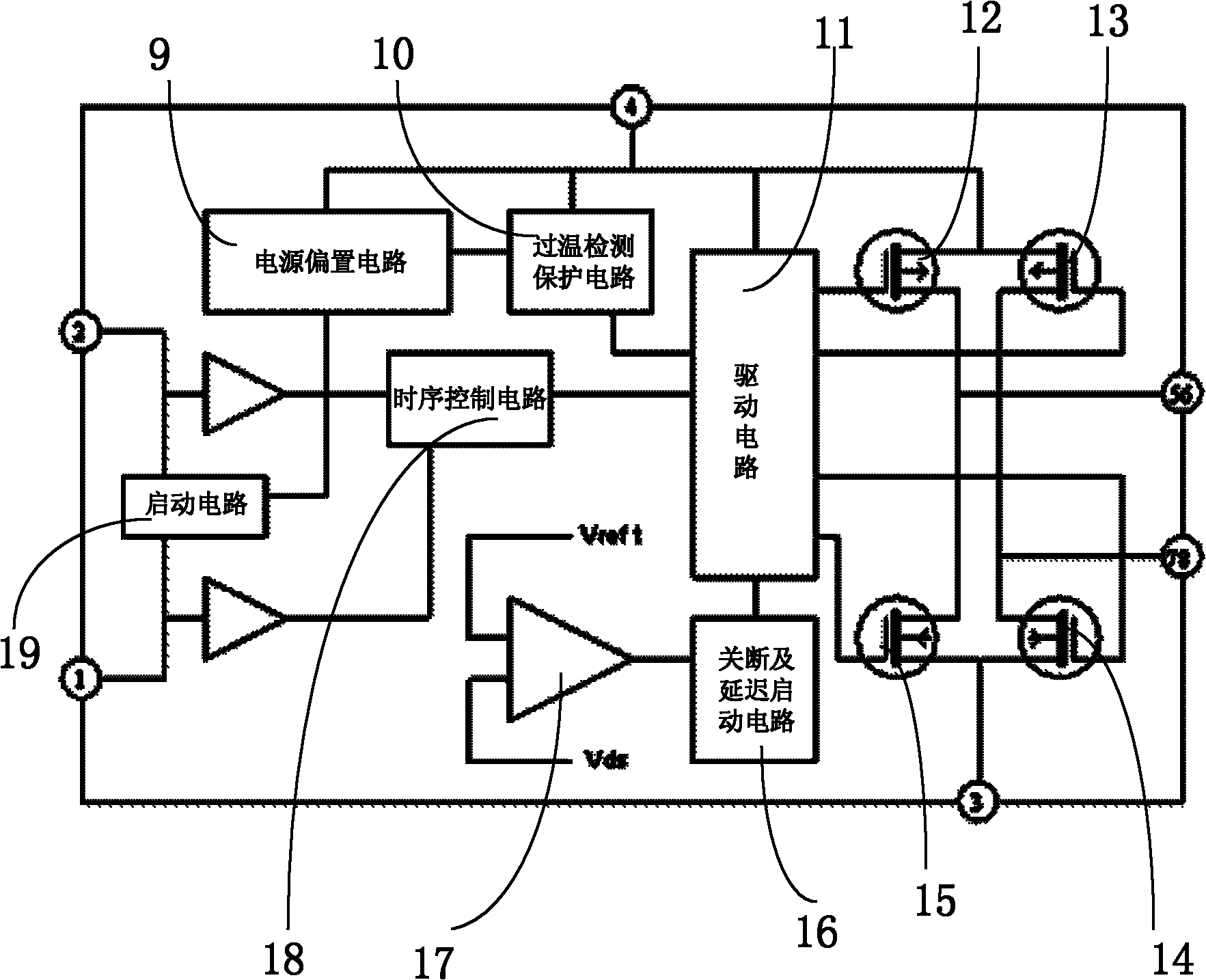

[0036] Such as Figure 1 to Figure 2 Shown: a kind of bidirectional DC motor driving integrated circuit of the embodiment of the present invention, comprises control chip 20 and the H-bridge switch circuit that is connected with control chip 20, and H-bridge switch circuit comprises the switch chip 12-15 that is connected with each other, bidirectional direct current The motor drive integrated circuit includes a forward rotation input terminal 2, a reverse rotation input terminal 1, a positive power supply 4, a negative power supply 3, positive output terminals 5, 6 and negative output terminals 7, 8. The control chip 20 includes a start-up circuit 19 , a power bias circuit 9 , an over-temperature detection and protection circuit 10 , a drive circuit 11 , a shut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com