Optical mechanical cold connector

A splicer, mechanical technology, applied in the coupling of optical waveguides, etc., can solve the problems of the quality of optical fiber butt joint, can not be reused, reduce the performance of light, achieve small thermal expansion and contraction coefficient, reduce operating errors, improve The effect of environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

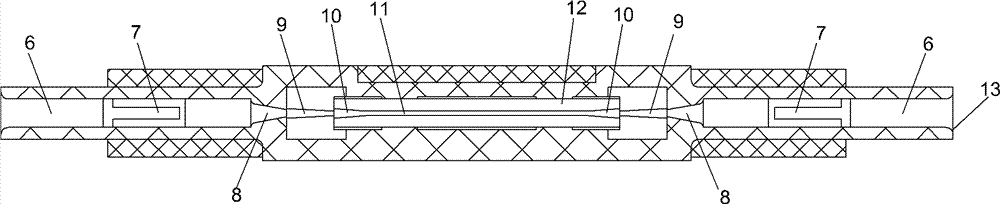

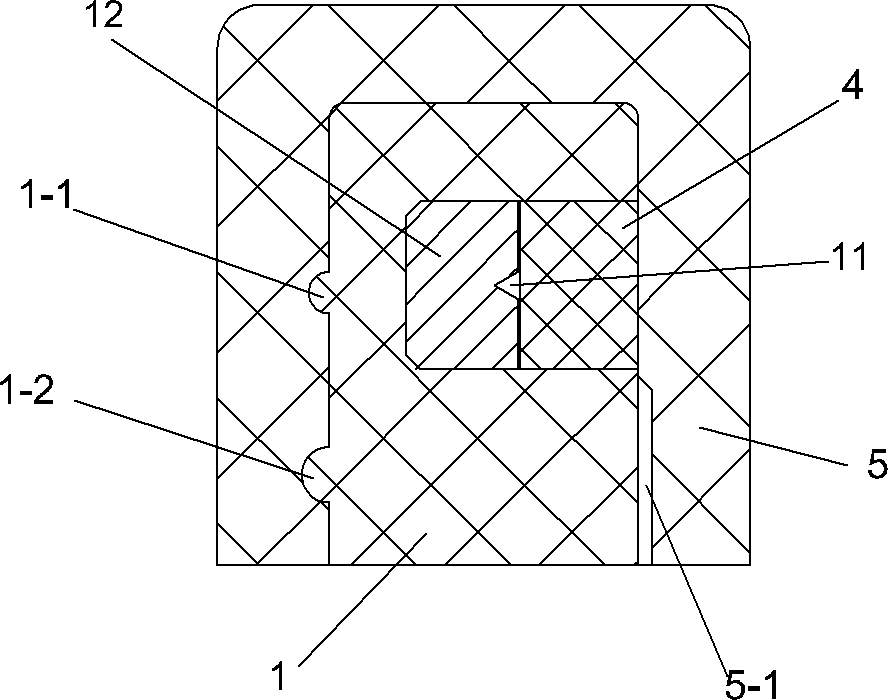

[0044] As shown in the figure, an optical fiber mechanical cold splicer according to the present invention includes a main body shell 1 (made of plastic) with a fixing groove 15 in the middle; a metal block 12 (such as Figure 6 As shown, several small bumps 16 can be made in the fixing groove, and then the metal block is pressed into the fixing groove by mechanical crimping), and the metal block is formed with a V-shaped groove 11 extending along the axis direction of the main body shell ( Conventional structure, the depth and width of the V-shaped groove are determined according to the specifications of the optical fiber), the openings of the fixing groove and the V-shaped groove are all facing the front side of the main body shell (direction reference figure 1 , outward along the paper).

[0045] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com