Underwater concrete pouring elevation control device and use method thereof

A control device and horizontal technology, applied in construction, infrastructure engineering, etc., can solve the problems of large impact on results, waste, and the need for electricity for instrument use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

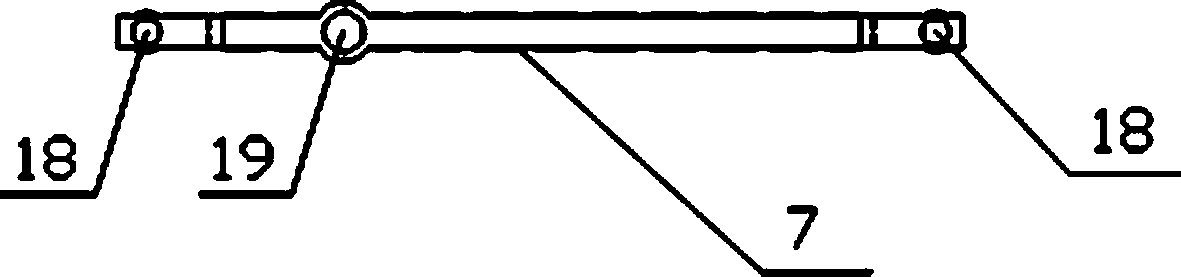

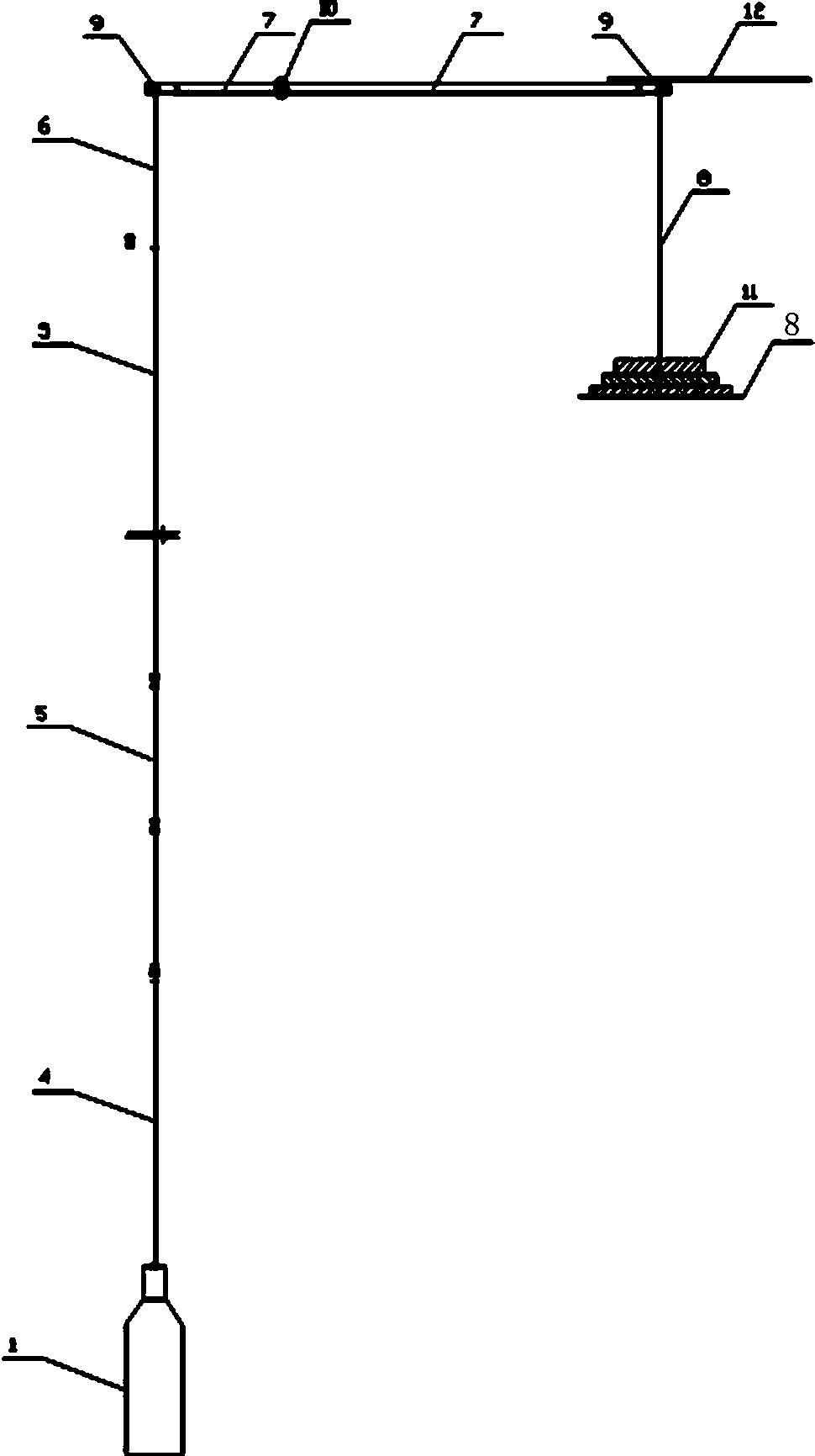

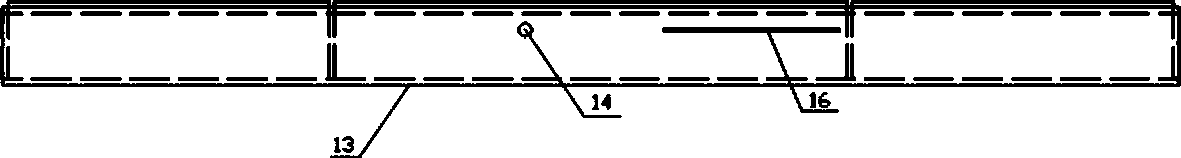

[0054] root tree figure 1 - Image 6 The shown underwater concrete pouring elevation control device of the present invention includes: the assembly positioning pin 10 with a locking mechanism passes through the assembly pair piercing hole 19 of the inlaid insulating hard snap ring reserved on the lever horizontal bar 7, with a lock One end of the assembly positioning pin 10 of the stop mechanism is provided with a locking pin 15, and the other end of the assembly positioning pin 10 with the locking mechanism is connected with the fixing bolt 14 of the assembly device; or upper scale rod), the upper adjustment rod 6 (or upper scale rod) of the active rod is directly connected with the lower scale rod 4 of the active rod, and the lowermost end of the lower scale rod 4 of the active rod is rigidly connected with the suspension device 1, which can be used in the suspension device 1. Bolts or rivets are used to fix and connect the upper end of the drill hole. The other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com