Hopping robot based on rotating plate/cylindrical pin driving mechanism

A driving mechanism and cylindrical pin technology are applied in the field of jumping robots to achieve the effects of simple and reliable triggering, reducing collision damage rate and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

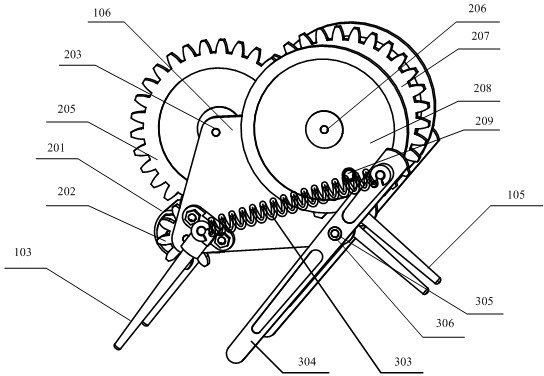

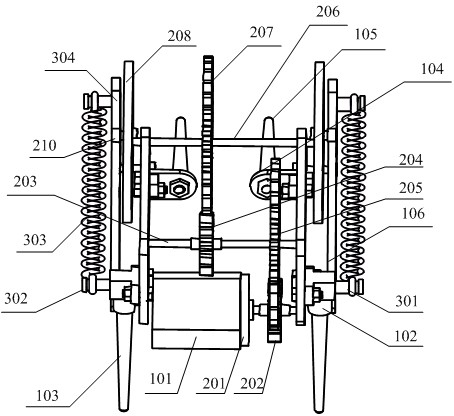

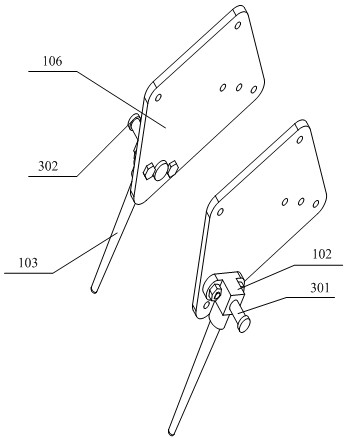

[0040] The present invention is installed with the power transmission device that realizes driving function on the body; On both sides of the body, stable supporting device and energy storage device are installed; figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6As shown, the two side plates 106 of the jumping robot body are drilled with through holes, on which the motor shaft 201, the secondary gear shaft 203, and the tertiary gear shaft 206 are installed, and the first pinion is installed on the motor shaft 201 by interference fit. 202, install the second pinion 204 and the first large gear 205 on the secondary gear shaft 203 through interference fit, and install the second large gear 207 and the first and second rotating gears on the third-stage gear shaft 206 through interference fit Disc 208 is drilled with through holes on the first and second rotating discs 208, and the first and second cylindrical pins 209 are connected with the holes on the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com