Plastic welding gun elastic fixture with two-way error compensation function for automatic welding

A plastic welding torch and automatic welding technology, which is applied in the field of welding torch installation fixtures, can solve the problems of low efficiency of artificial plastic welding, low dimensional accuracy of the welded seam, and difficulty in applying automatic welding, etc., to achieve good motion flexibility, improve welding quality, The effect of strong error compensation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

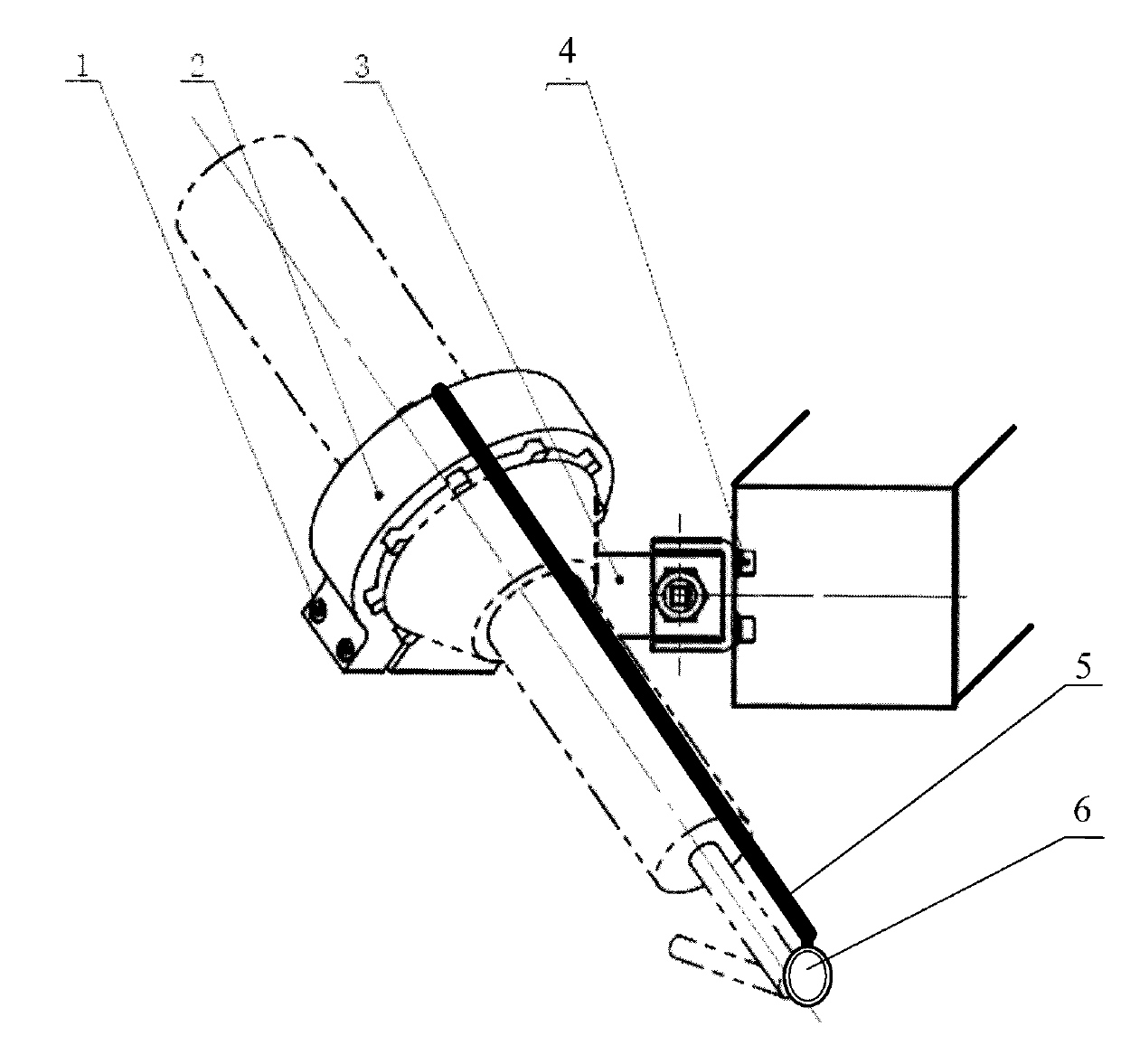

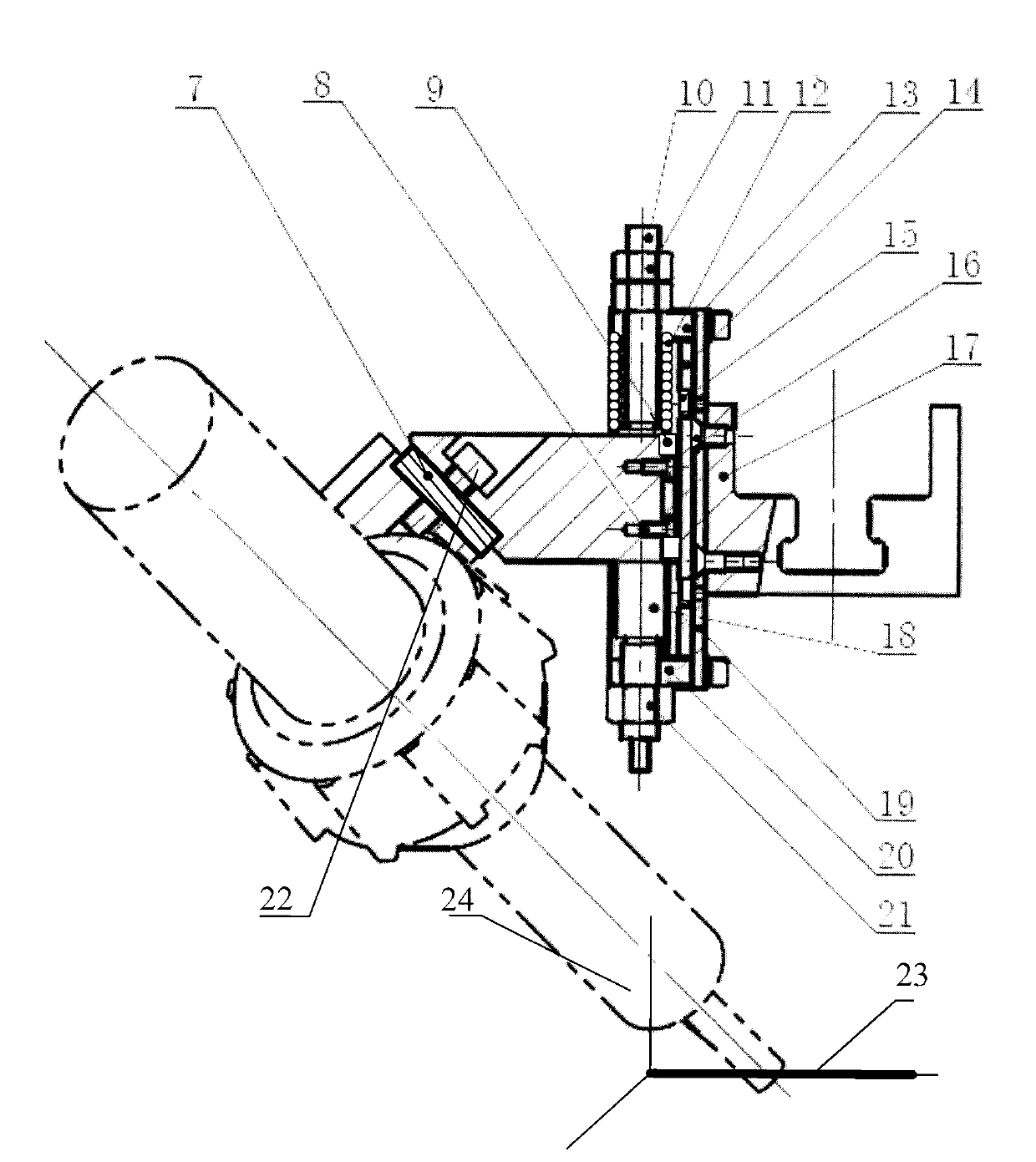

[0016] Such as figure 1 and figure 2 As shown, the plastic welding torch elastic clamp for automatic welding with bidirectional error compensation includes elastic clamp 2, stud shaft 22, rotating spring disc 7, inclined plane connecting block 3, compression spring 12, spring adjusting nut 11, translation adjusting nut 21. Compression spring rod 10, translational adjustment rod 18, upper connecting plate 13, lower connecting plate 20, translational sliding guide rail 14, slider 9, porous position mounting plate 19, mounting base 17, guide wheel rod 5 and ellipse Bead guide wheel6.

[0017] The elastic clamp 2 is stuck on the cylinder in the middle of the plastic welding torch 24, the elastic clamp 2 is not closed, and there is an open platform at the bottom, and the opening size of the elastic clamp 2 can be adjusted by tightening or loosening the hexagon socket head scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com