Electrochemical machining array electrode

An array electrode and electrolyte technology, which is used in processing electrodes, electric processing equipment, electrode manufacturing, etc., can solve the problems of difficult discharge of heat and electrolysis products, high processing accuracy and processing stability, and unstable electric field and flow field. Achieve the effect of shortening production cycle, improving processing efficiency and processing quality, and uniform electric field and flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

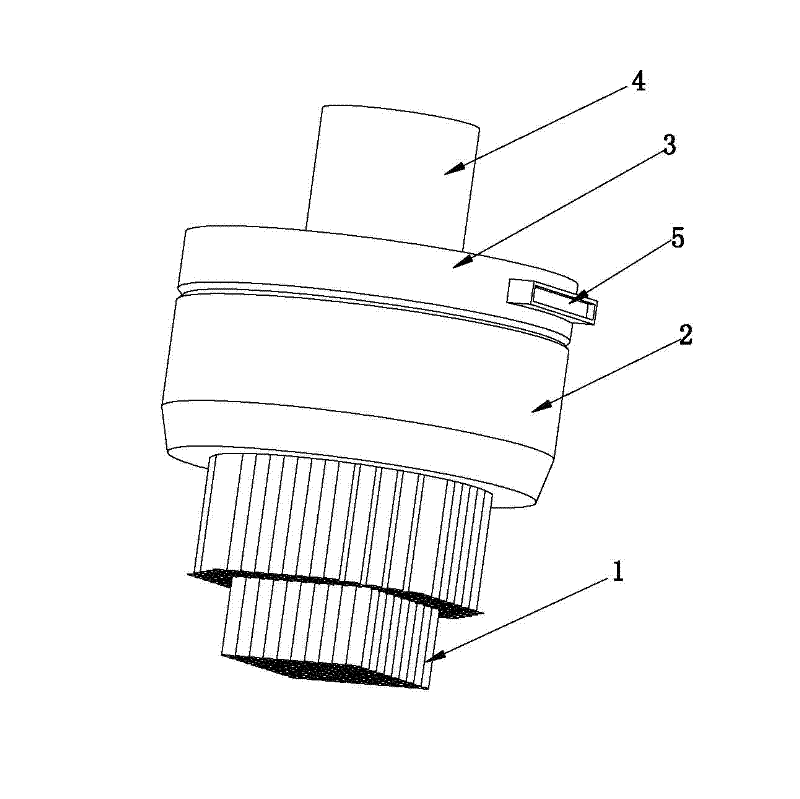

[0025] like figure 1 shown.

[0026] An electrolytic machining array electrode, which includes an electrode unit 1. When the electrode unit 1 is a strip-shaped entity, the array electrode is sequentially composed of an electrode unit 1, an electrode unit bundle clamp 2, a power module 3, and an electrode clamp joint 4. , the electrode units 1 are bundled to form an array electrode unit bundle, and the array electrode unit bundle is clamped by the electrode unit bundle clamp 2, and the bottom end of the array electrode unit bundle can form an end surface of any contour shape. The electrode units 1 can be completely conductive or completely insulated, or partially conductive to form electrode unit groups, which are insulated from each other and powered by an external power supply via the power interface 5 of the power module 3 . When the electrode units 1 are completely insulated or partially conductive and partially insulated to form a group, the electrode units 1 can be selec...

Embodiment 2

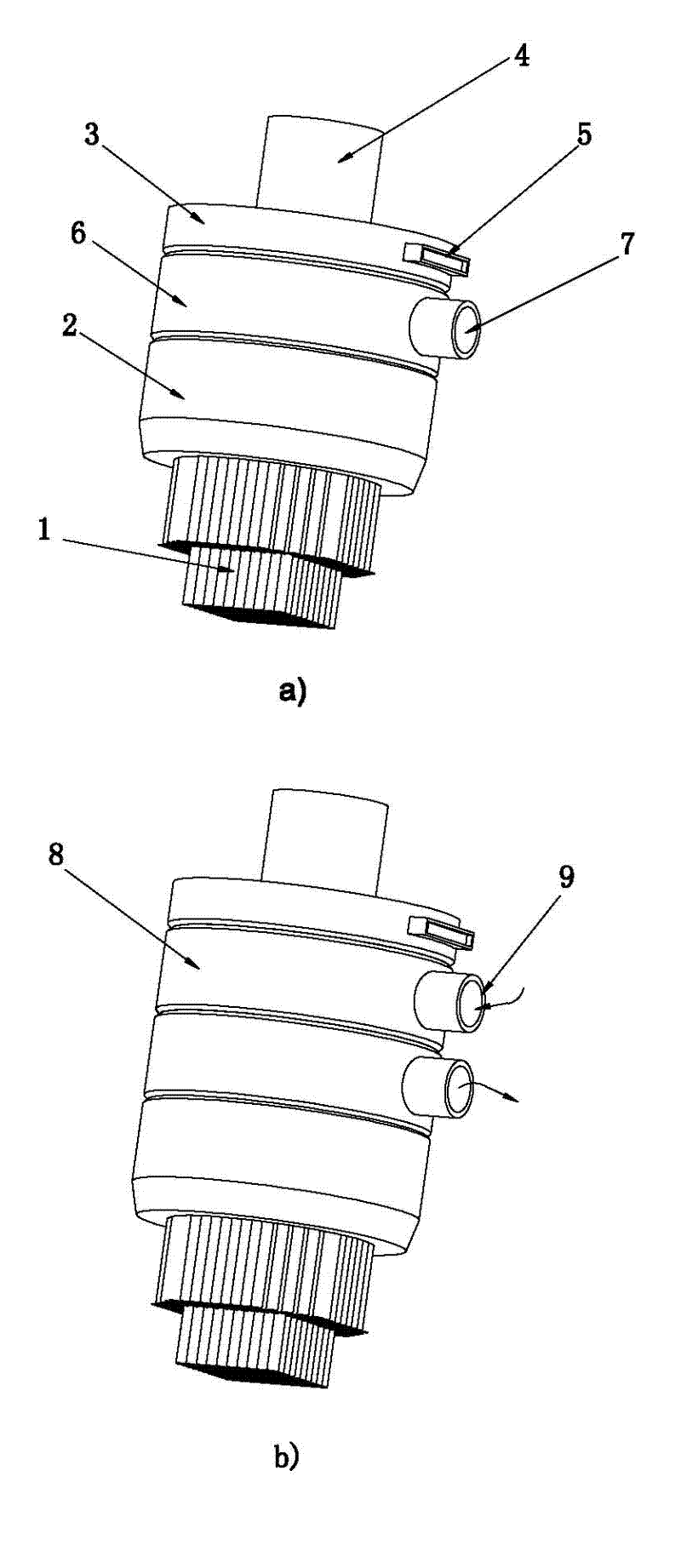

[0028] like figure 2 , 3 shown.

[0029] The difference between this embodiment and the first embodiment is that the section of the electrode unit 1 is hollow or slotted, figure 2 The electrode unit 1 is a thin-walled hollow or slotted structure. in figure 2 (a) Array electrode when adding an electrolyte module, figure 1 (b) Array electrode when adding two electrolyte modules. When the electrode unit is a thin-walled hollow structure or a slotted structure, the electrolytic machining array electrode also includes an electrolyte module 6, so that the electrode unit 1 can realize liquid flushing or liquid absorption, or add two electrolyte modules 6 and 8, respectively with different The electrode units 1 are connected, so that part of the electrode units 1 flush liquid, and part of the electrode units 1 absorb liquid. The electrolyte module is provided with electrolyte interfaces 7 and 9 .

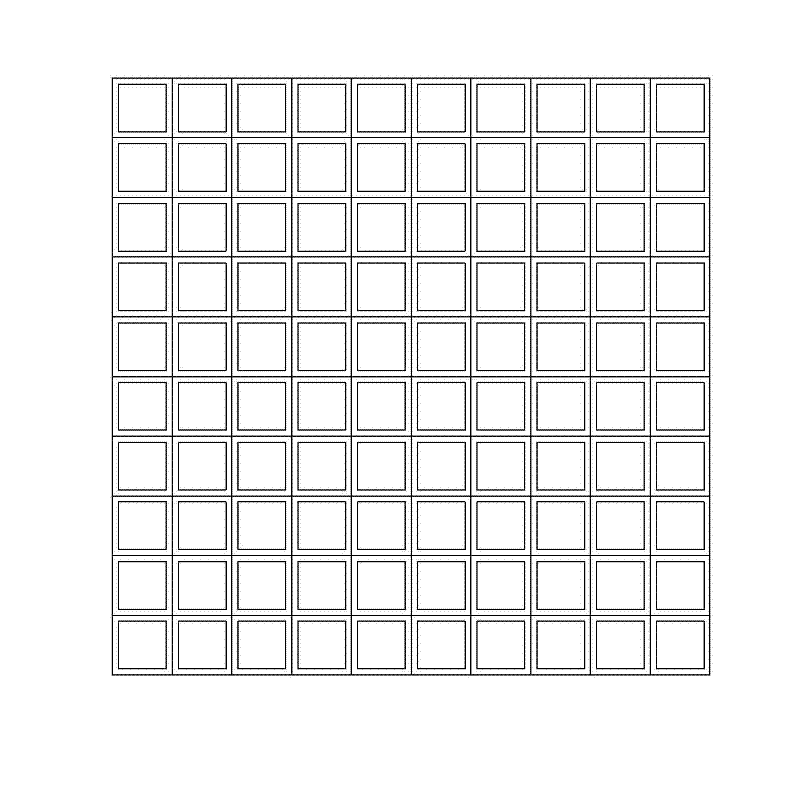

[0030] image 3 It is a schematic plan view of quadrilateral section electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com