High-deformation press forging forming process for A 5052-H32 aluminum alloy mobile phone shell with convex post

A technology of A5052-H32 and large deformation, which is applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of lack of theoretical analysis means, the accuracy and reliability of the solution, and achieve the blank shape Simplicity, shorter design and manufacturing cycles, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further illustrated by the following embodiments, and the present invention is not limited to the described embodiments, and all structures similar to the present invention, but those that are only adjusted or changed in size and position all belong to the protection category of the present invention.

[0027] The method of the present invention will be described below by taking the punching and forging of the mobile phone shell with the boss and the side wall as an example:

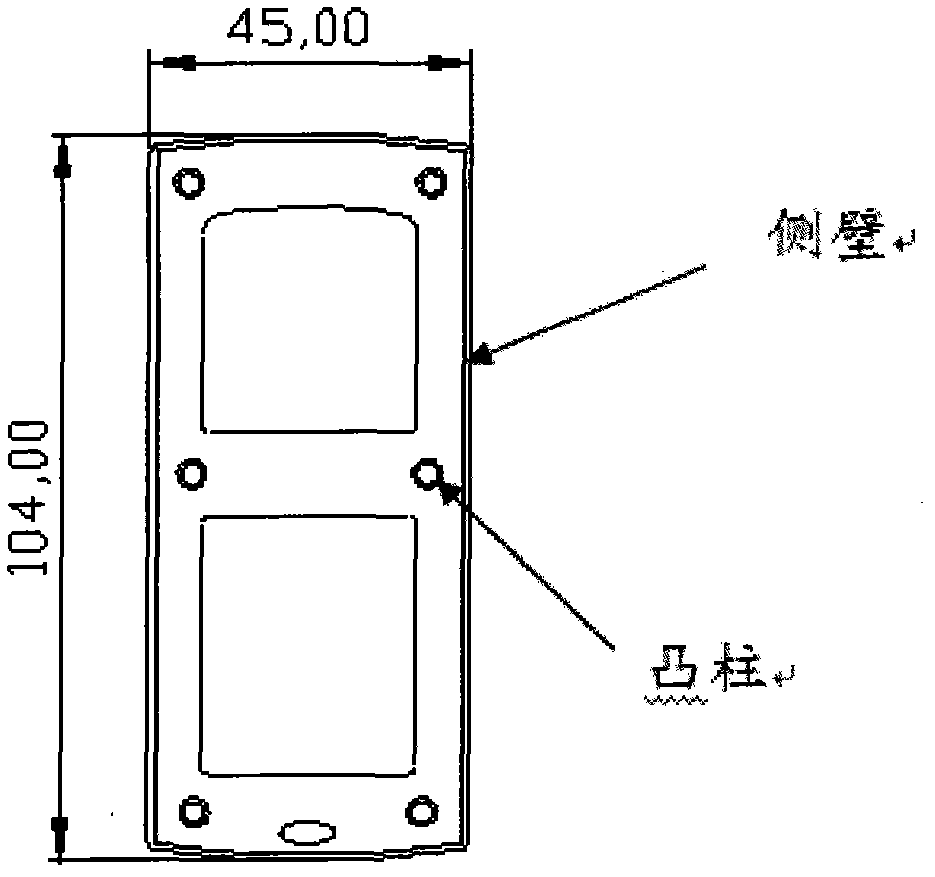

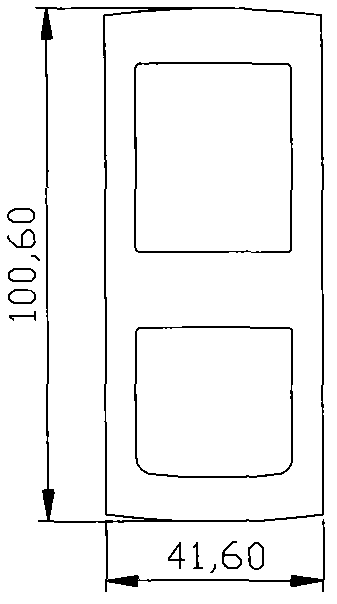

[0028] Mobile phone case parts see figure 1 , figure 2 , There are six solid bosses with the same size on the bottom of the shell, the height of the six bosses is the same, and the back of the boss is the appearance surface, no depression is allowed. Only when the height of the side wall of the mobile phone case is consistent can the assembly requirements of the mobile phone be met. If the height difference of the side wall of the punched and forged mobile phone case is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com