Plate rolling machine

A technology of plate rolling machine and rolling roller, which is applied in the direction of mechanical equipment, belt/chain/gear, transmission device, etc., can solve the problems that the central rolling roller cannot be made too thin, troublesome to take out the workpiece, low work efficiency, etc., to achieve production efficiency Improved, improved manufacturing accuracy, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will now be described with reference to the drawings, wherein like reference numerals designate like or similar devices throughout.

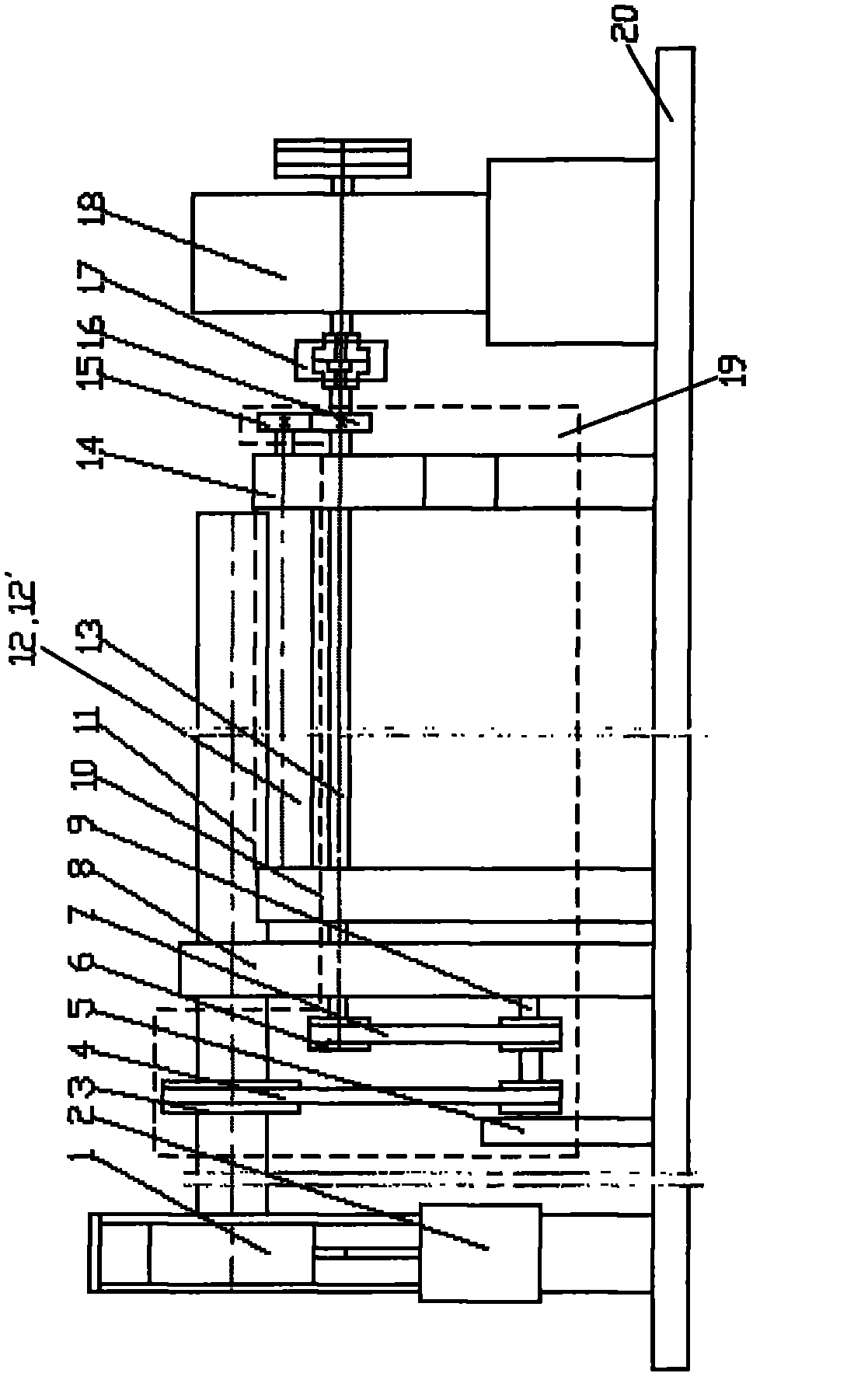

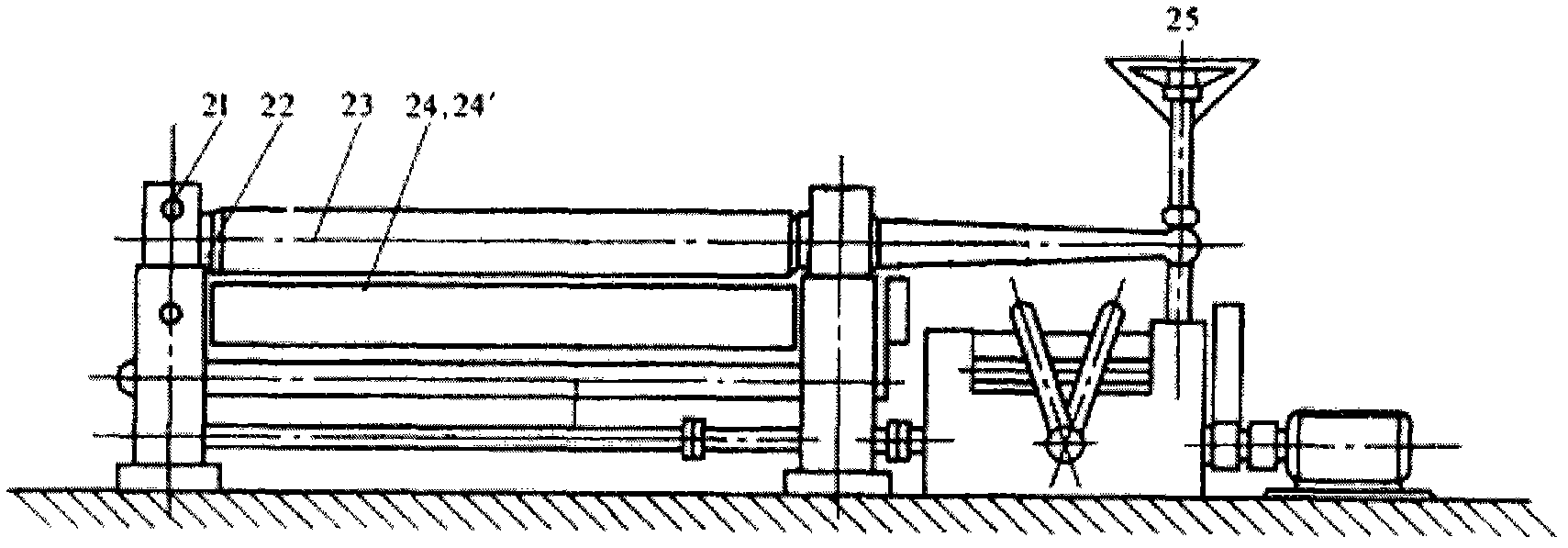

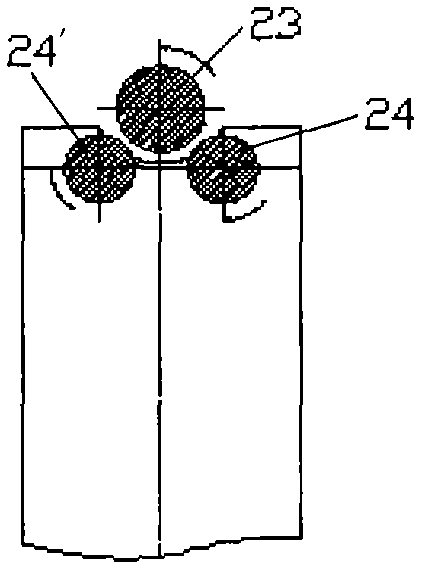

[0019] figure 1 is a schematic front view of the structure of the plate bending machine according to the preferred embodiment of the present invention. In this preferred embodiment, the plate rolling machine of the present invention realizes all active drives of the three winding rollers (the upper winding roller and the first and second lower winding rollers) while realizing the open structure. and figure 2 The plate rolling machine shown in the prior art is similar, figure 1 The plate rolling machine of the present invention shown also includes a frame 20, an upper roll 11 mounted on the frame, a first lower roll 12 and a second lower roll 12'. Similar to the prior art, the plate bending machine of the present invention may also include a speed reducer 17 . The specific implementation of this preferred embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com