Device for manufacturing absorbing body and method of manufacturing gas permeable member

A technology for manufacturing equipment and absorbers, applied to absorbent pads, chemical instruments and methods, clothing, etc., can solve problems such as fatigue fractures, and achieve the effect of deformation suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0073]

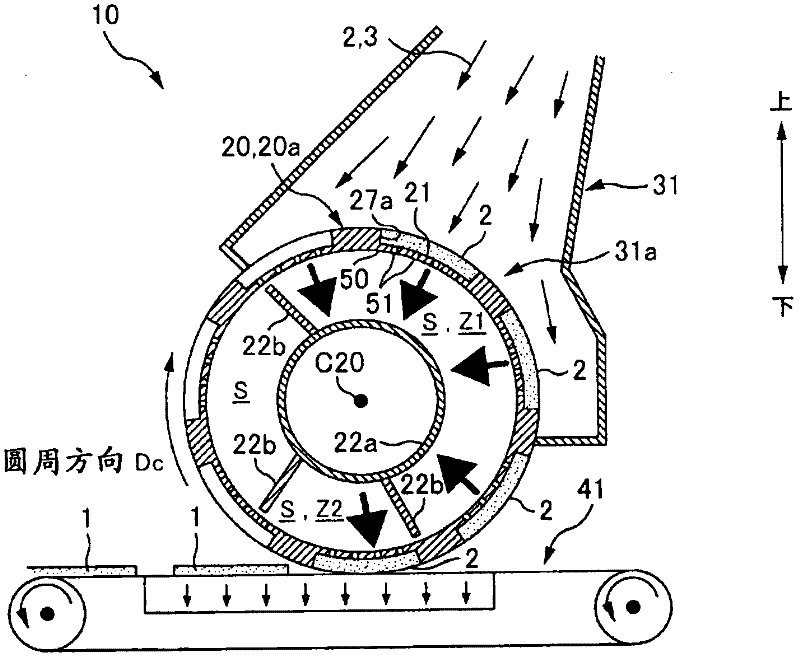

[0074] figure 1 is a sectional view of an example of the manufacturing apparatus 10 of the absorbent body 1 , here, the apparatus 10 is sectioned at its center along its longitudinal direction.

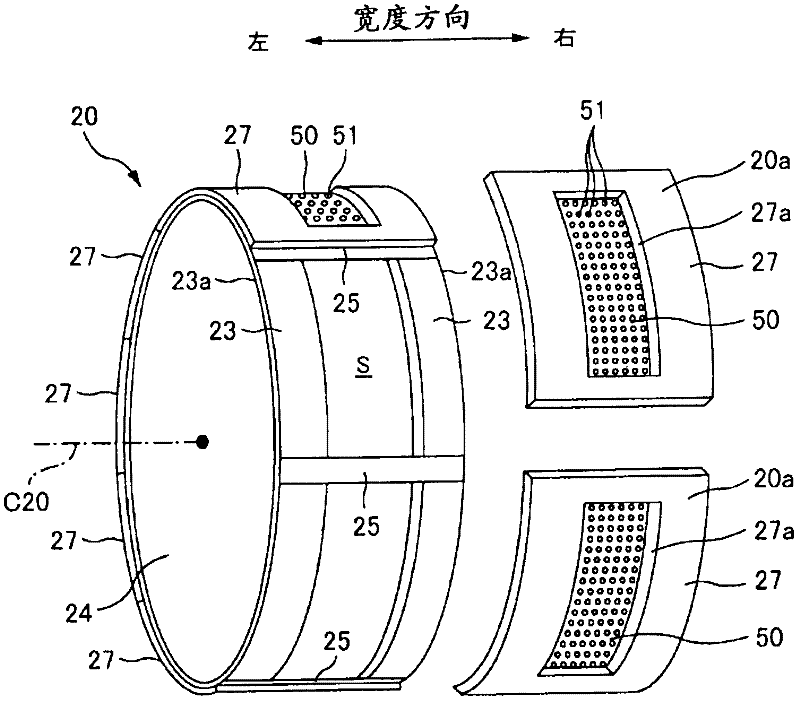

[0075] This absorbent body 1 manufacturing apparatus 10 is a so-called fiber depositing apparatus in which the absorbent body 1 is formed by depositing pulp fibers 2 as a liquid absorbent material. The main structure of the manufacturing apparatus 10 includes, for example: (1) a rotating drum 20 that continuously rotates around a horizontal axis C20 in one direction (circumferential direction Dc, such as a clockwise direction); 20a distributes and supplies a supply pipe 31 of mixed air 3 containing pulp fibers 2 (corresponding to air), the supply port 31a is provided at a predetermined position (corresponding to the first position) on the circumferential direction Dc of the drum 20; and (3 ) Adsorption transfer device 41 provided downstream of the supply pipe 31 in the cir...

no. 1 approach

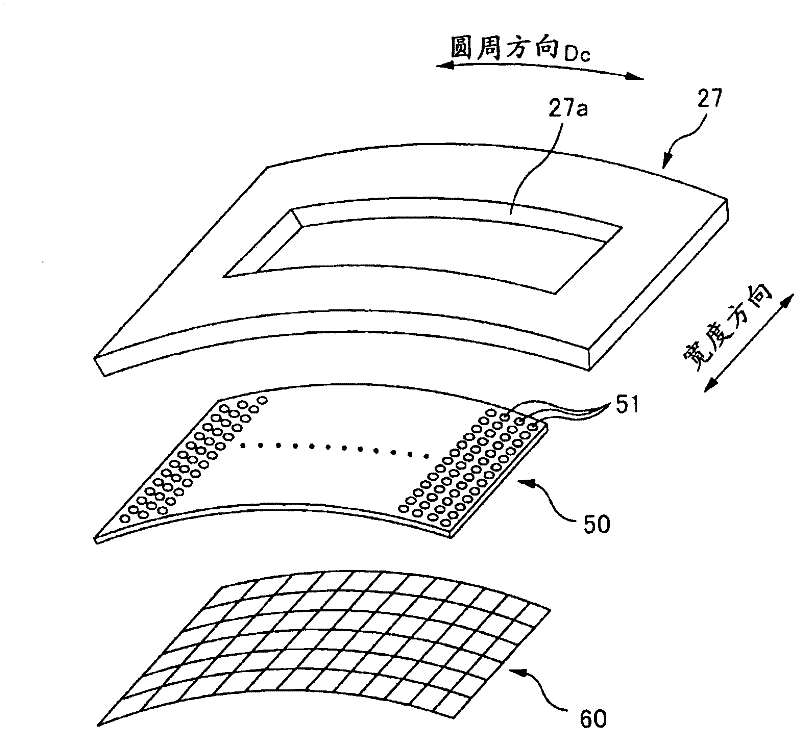

[0097] Figures 5A to 5C A first embodiment of the air-permeable member 50 and the reinforcement member 60 is illustrated. Figure 5A is a plan view of the air-permeable member 50 whose illustration is partially omitted; Figure 5B and 5C respectively in Figure 5A B-B cross-section and C-C cross-section taken in .

[0098] The air-permeable member 50 according to the first embodiment is a mesh formed by weaving third threads 53 and fourth threads 54 crossing each other, more specifically, a plain weave cloth. Its mesh serves as the aforementioned air vent 51 . On the other hand, the reinforcing member 60 is a plain weave cloth formed by weaving the first wire 61 and the second wire 62 having a diameter larger than that of the third wire 53 and the fourth wire 54 . In this example, both woven screen cloths are made of metal wire such as stainless steel wire (SUS304 in this example), but non-metal such as resin, etc. can also be used if the plate has suitable rigidity and ...

no. 2 approach

[0121] Figures 8A to 8C A second embodiment of the air-permeable member 50a and the reinforcement member 60 is illustrated. Figure 8A is a plan view of the ventilation member 50a whose illustration is partially omitted; Figure 8B and 8C respectively in Figure 8A B-B cross-section and C-C cross-section taken in . exist Figure 8B and 8C In the figure, the ventilation hole 51a of the ventilation member 50a is omitted to avoid the complexity of these drawings.

[0122] In the first embodiment, a woven mesh is used as the air-permeable member 50 . This second embodiment differs therefrom in using a plate-shaped member, but is basically the same in other points. Therefore, the same reference numerals are used for the same configurations, and descriptions thereof are omitted.

[0123] The air-permeable member 50a is a metal plate such as a stainless steel plate (SUS304 in this example) having a predetermined thickness (0.3 mm thick here). A non-metallic plate such as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com