Metal oxide modified TiO2 nanometer tube array electrode and preparation method thereof

A nanotube array and nanotube technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of few reports on the preparation methods of nanotube electrodes, achieve good photoelectric catalytic activity and visible light response characteristics, Effect of increased absorption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

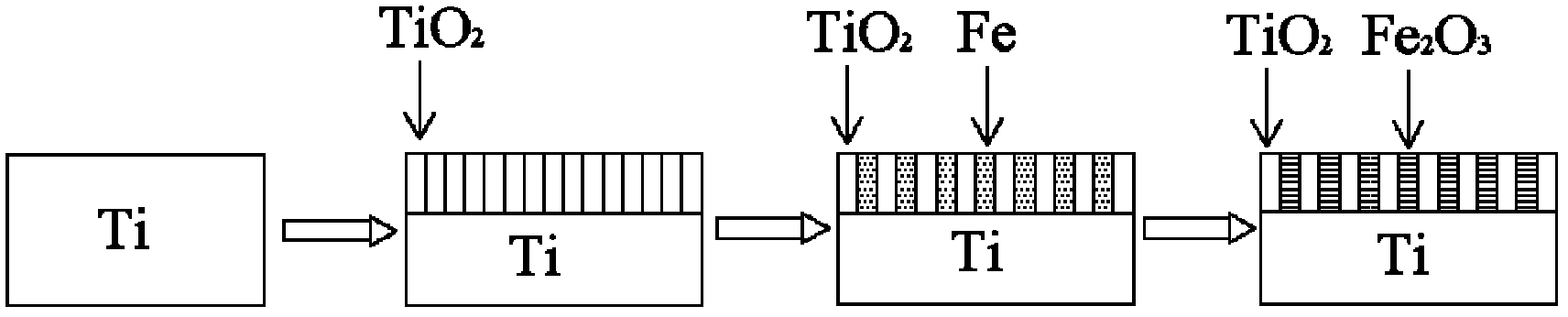

[0033] Taking metal Fe as an example, the preparation process is as follows figure 1 shown.

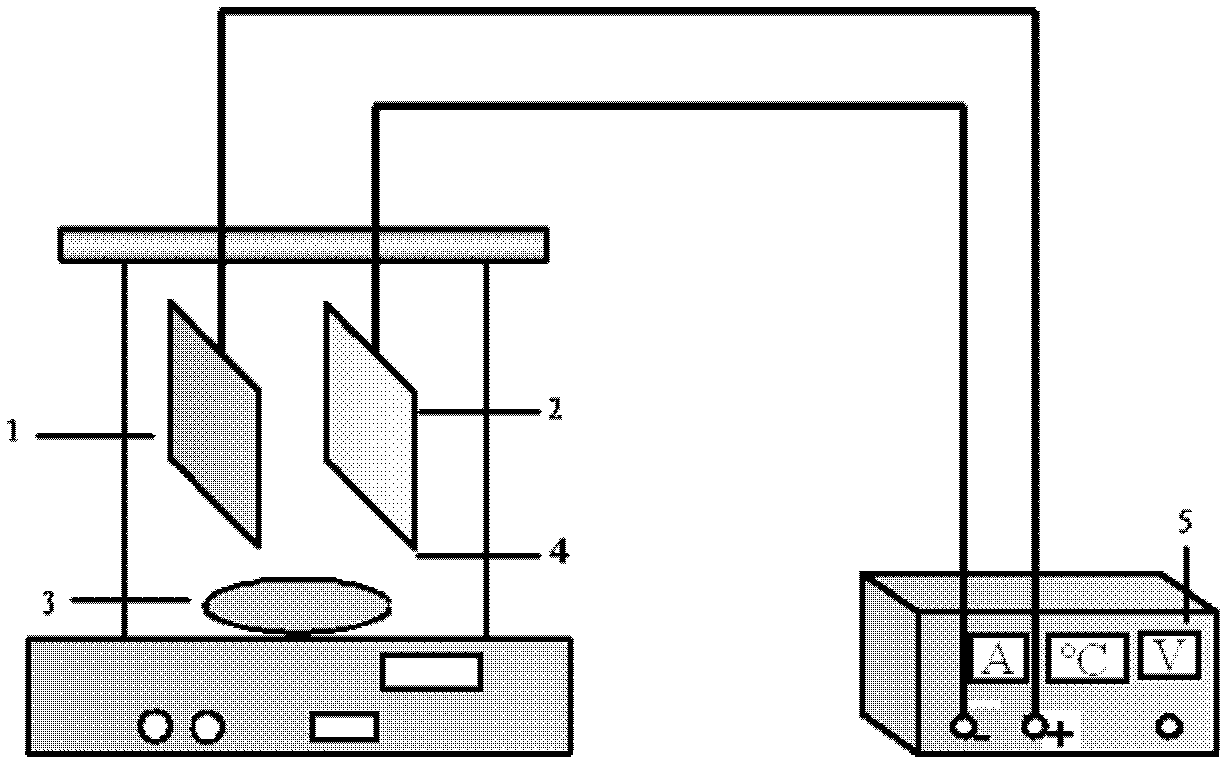

[0034] figure 2 Preparation of TiO for anodic oxidation 2 The schematic diagram of the device of the nanotube electrode, including a titanium sheet 1, a counter electrode 2, a magneton 3, a reaction solution 4, and a DC stabilized power supply 5.

[0035] 1) Pure titanium sheet (thickness 0.35mm, area 5cm 2 ) with sandpaper until the surface is smooth, and then ultrasonically clean with acetone, absolute ethanol and deionized water for 10 min each. With the titanium plate as the anode and the copper sheet (2cm*4cm) as the cathode, it contains 0.5wt% NaF and 0.5MNa 2 SO 4 In aqueous solution, anodized at a constant oxidation voltage of 20V for 5h. Rinse the prepared sample with deionized water, air-dry, heat up to 500°C at 2°C / min in an air atmosphere, then anneal at a constant temperature for 2 hours, and then cool at a rate of 30°C / min to obtain TiO 2 Nanotube array electrode...

Embodiment 2

[0040] 1) Pure titanium sheet (thickness 0.35mm, area 5cm 2 ) with sandpaper, and then ultrasonically cleaned with acetone, absolute ethanol and deionized water for 10 min each. With a titanium plate as the anode and a copper sheet (2cm*4cm) as the cathode, in a solution containing 0.5wt% NaF and 0.5M Na 2 SO 4 In aqueous solution, anodized at a constant oxidation voltage of 20V for 5h. Rinse the prepared sample with deionized water, air-dry, heat up to 500°C at 2°C / min in an air atmosphere, then anneal at a constant temperature for 2 hours, and then cool at a rate of 30°C / min to obtain TiO 2 Nanotube array electrodes.

[0041] 2) Prepare 0.1M Cu(NO 3 ) 2 solution, the TiO 2 The nanotube array electrode was immersed in it for 20min and sonicated. Then with the TiO 2 The nanotube array electrode is the cathode, the platinum sheet is the anode, 0.1M Na 2 SO 4 As electrolyte, constant voltage 8V, electrolyte temperature 85°C, electrodeposition for 20min. Turn off the p...

Embodiment 3

[0044] 1) Pure titanium sheet (thickness 0.35mm, area 5cm 2 ) with sandpaper, and then ultrasonically cleaned with acetone, absolute ethanol and deionized water for 10 min each. With a titanium plate as the anode and a copper sheet (2cm*4cm) as the cathode, in a solution containing 0.5wt% NaF and 0.5M Na 2 SO 4 In aqueous solution, anodized at a constant oxidation voltage of 20V for 5h. Rinse the prepared sample with deionized water, air-dry, heat up to 500°C at 2°C / min in an air atmosphere, then anneal at a constant temperature for 2 hours, and then cool at a rate of 30°C / min to obtain TiO 2 Nanotube array electrodes.

[0045] 2) Prepare 0.1M Ni(NO 3 ) 2 solution, the TiO 2 The nanotube array electrode was immersed in it for 20min and sonicated. Then with the TiO 2 The nanotube array electrode is the cathode, the platinum sheet is the anode, 0.1M Na 2 SO 4 As electrolyte, constant voltage 8V, electrolyte temperature 85°C, electrodeposition for 20min. Turn off the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com