Method for regulating and controlling water quality of fully enclosed circulation sea-water industrial mariculture

A fully enclosed technology for aquaculture water quality, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Achieve the effect of saving electric energy and water energy, saving water energy and electric energy, and increasing the production of aquaculture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples serve to illustrate the invention.

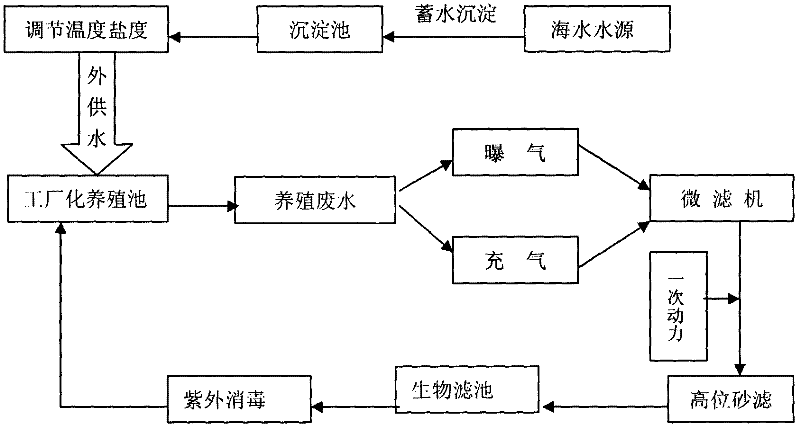

[0028] Take Jiangpeng Aquaculture Science and Technology Development Co., Ltd. in Qinhuangdao, Hebei Province, as an example by using the present invention to carry out the recycling treatment of aquaculture wastewater. For details on the aquaculture water cycle, see figure 1 .

[0029] The method applied in this embodiment includes the following steps:

[0030] (1) The sea water source is purified by the sedimentation tank, and the salinity and temperature are adjusted to supply water to the breeding pond;

[0031] The water temperature is controlled at 15-17°C and the salinity is 28-30‰.

[0032] (2) After the aquaculture wastewater discharged from the aquaculture pond flows into the water collection tank through the sewage tank, it is sent to the filter device for mechanical filtration, so that the aquaculture wastewater is separated from the solid and liquid, and the particles with a particle size of 60 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com