Switchgear with rocker, especially protective switch

A switchgear and spring element technology, applied in the field of protection switches, can solve problems such as large space requirements for installation components, and achieve the effects of simplifying installation, reducing stroke loss, and contributing to structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

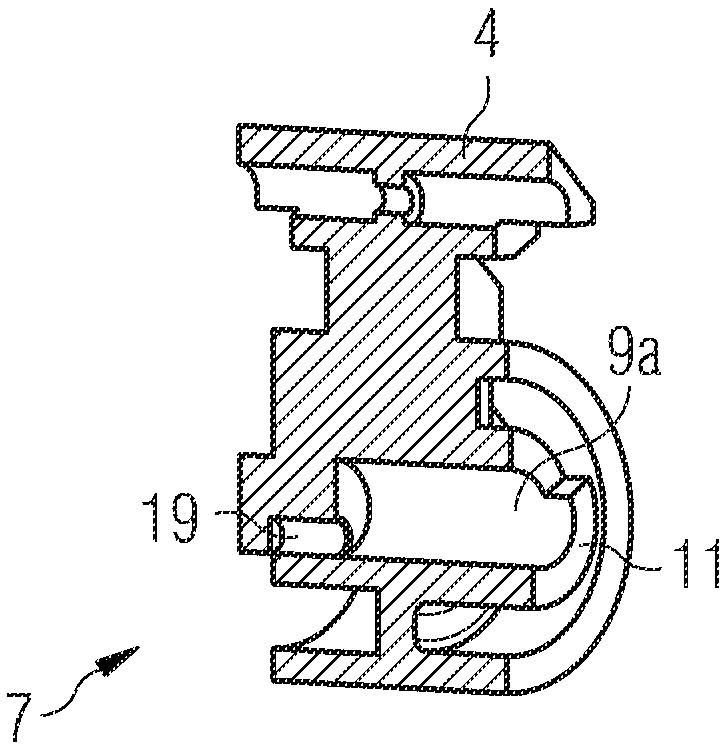

[0034] figure 1 a shows a housing part 100 of a prior art switchgear, in particular a protective switch. The housing part 100 has a cylindrically formed bearing neck 101 which is designed to support the switchgear in the figure 1 A manually operable rocker 102 is shown in b. The rocker 102 basically includes a base 103 and a handle 104 formed in a cylindrical manner. In the cylindrical base body 103 , a cylindrical hollow space is formed in the center, which is provided for receiving the bearing neck 101 .

[0035] exist figure 1 Shown in c is a spring 105 known from the prior art, which can be mounted to figure 1 a on the support neck 101. exist figure 1d shows the assembly of the housing cover 106 , the rocker 102 and the spring 105 , wherein the spring 105 is here arranged on the bearing neck 101 .

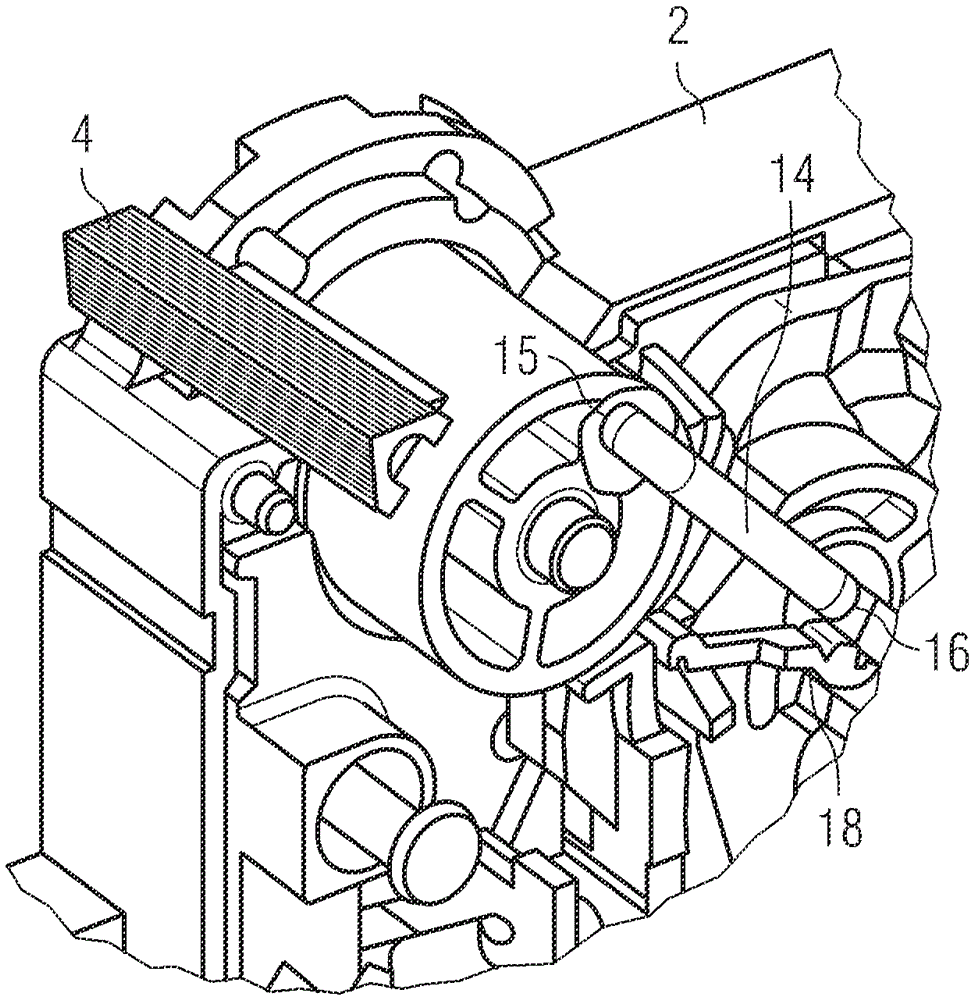

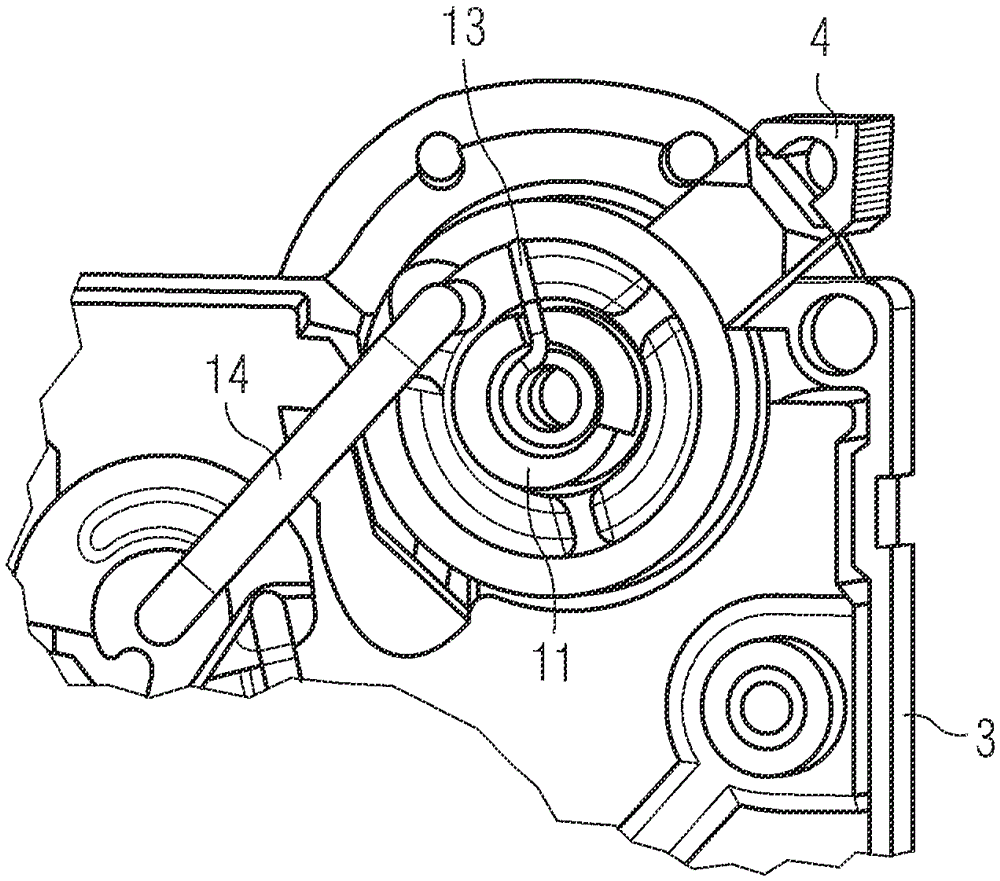

[0036] figure 2 A switching device 1 , in particular a protective switch, is shown. The switching device 1 is formed from two housing parts 2 , 3 which join together....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com