Insulation monitor and monitoring method thereof

An insulation monitor and insulation monitoring technology, applied in the direction of instruments, measuring equipment, measuring devices, etc., can solve the problem of not being able to monitor whether the three busbars are grounded in real time, and achieve the effect of easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

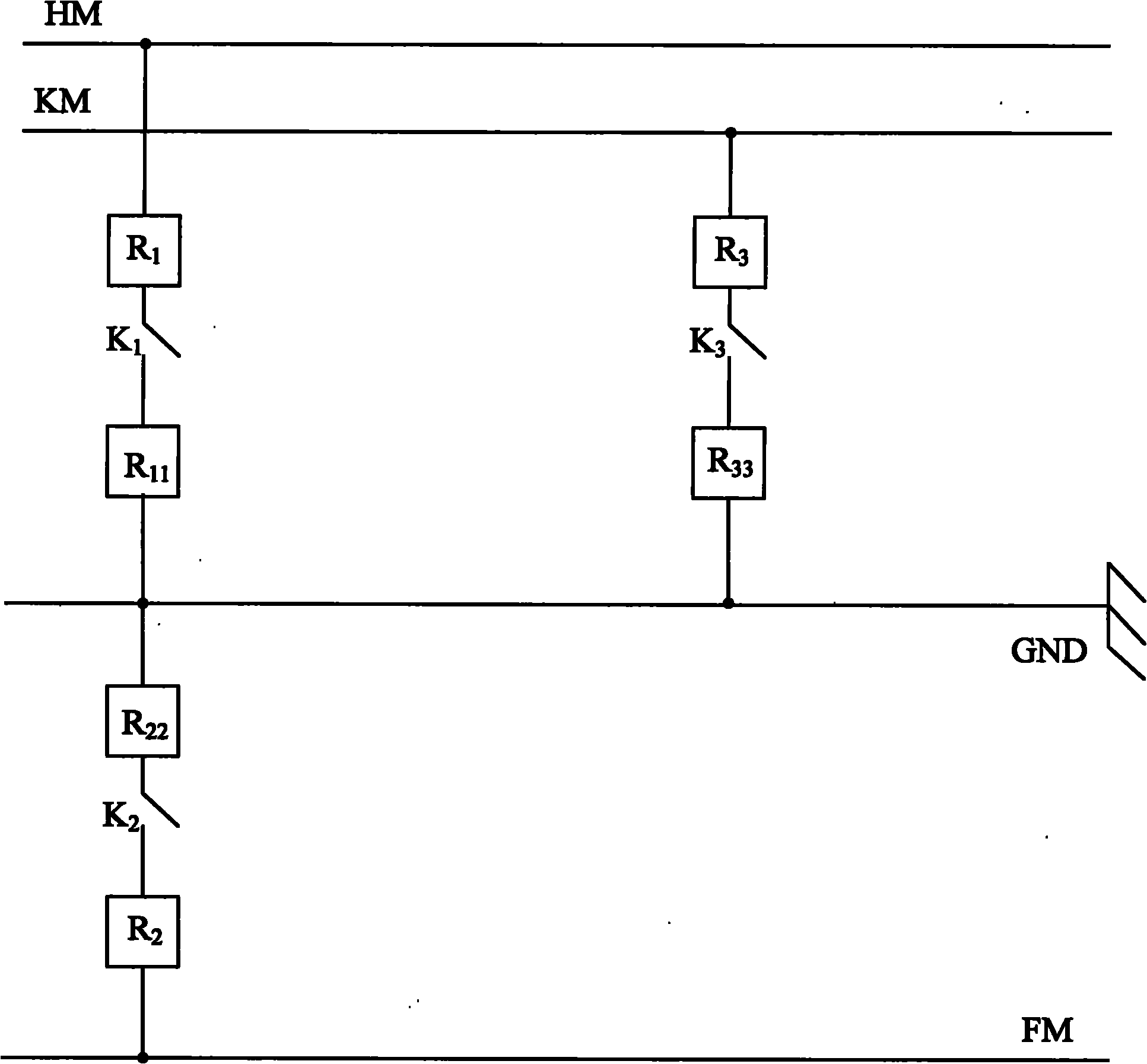

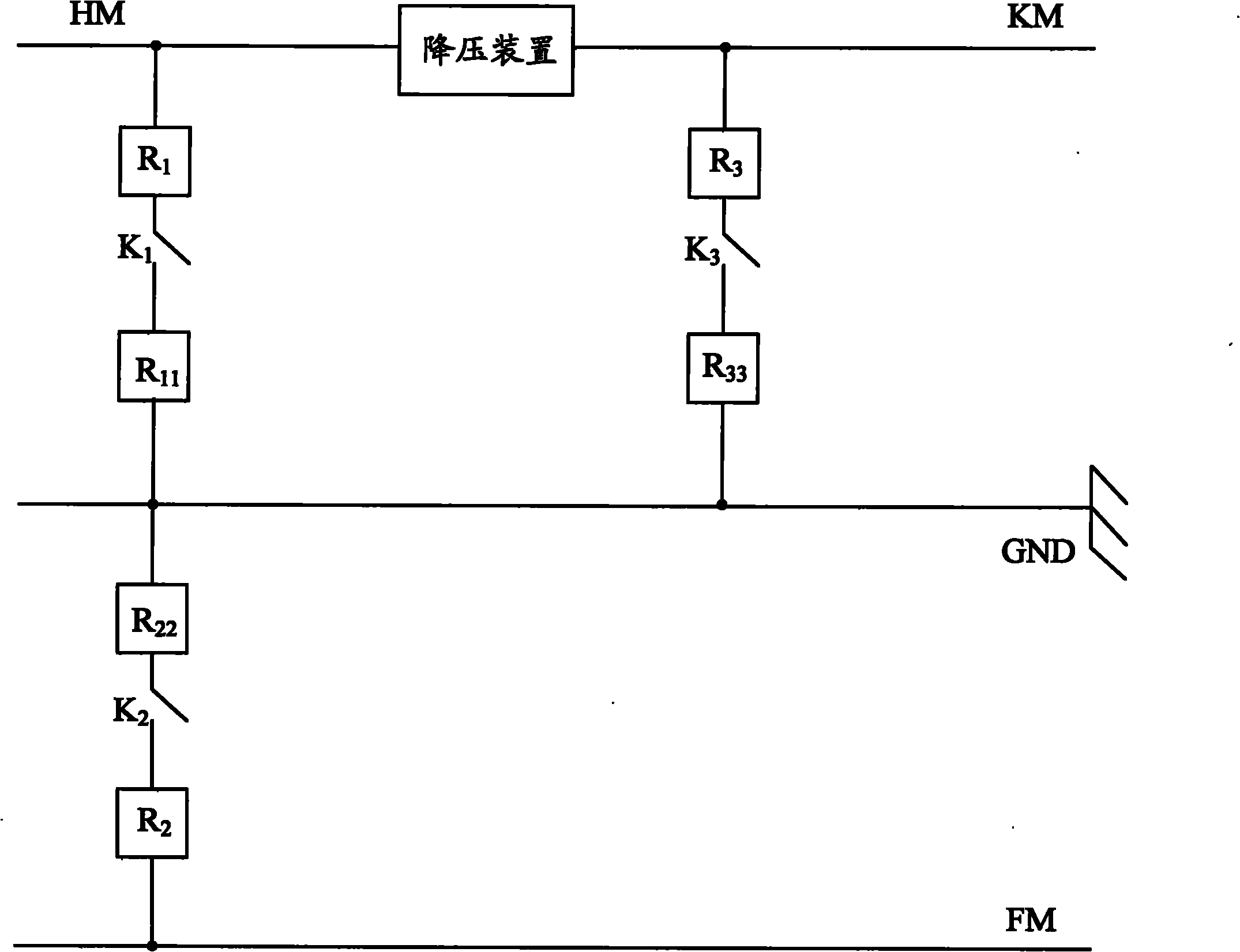

[0040] Step 20: Connect resistor R1, switch K1, and sampling resistor R11 in series from the bus bar HM to the ground line GND, and connect sampling resistor R22, switch K2, and resistor R2 in series from the ground line GND to the bus bar FM, from the bus bar KM to the ground In the direction of line GND, resistor R3, switch K3 and sampling resistor R33 are sequentially connected in series (see figure 2 ).

[0041] Step 11:

[0042] Close the switch K1 and switch K2, measure the voltage across the sampling resistors R11 and R22, and then obtain the voltage U1 between the bus HM and the bus FM through the principle of resistance voltage division;

[0043] Close the switch K2 and switch K3, measure the voltage across the sampling resistors R33 and R22, and then obtain the voltage U2 between the bus KM and the bus FM through the principle of resistance voltage division;

[0044] Close the switch K1, measure the voltage at both ends of the sampling resistor R11, and then obtai...

Embodiment 5

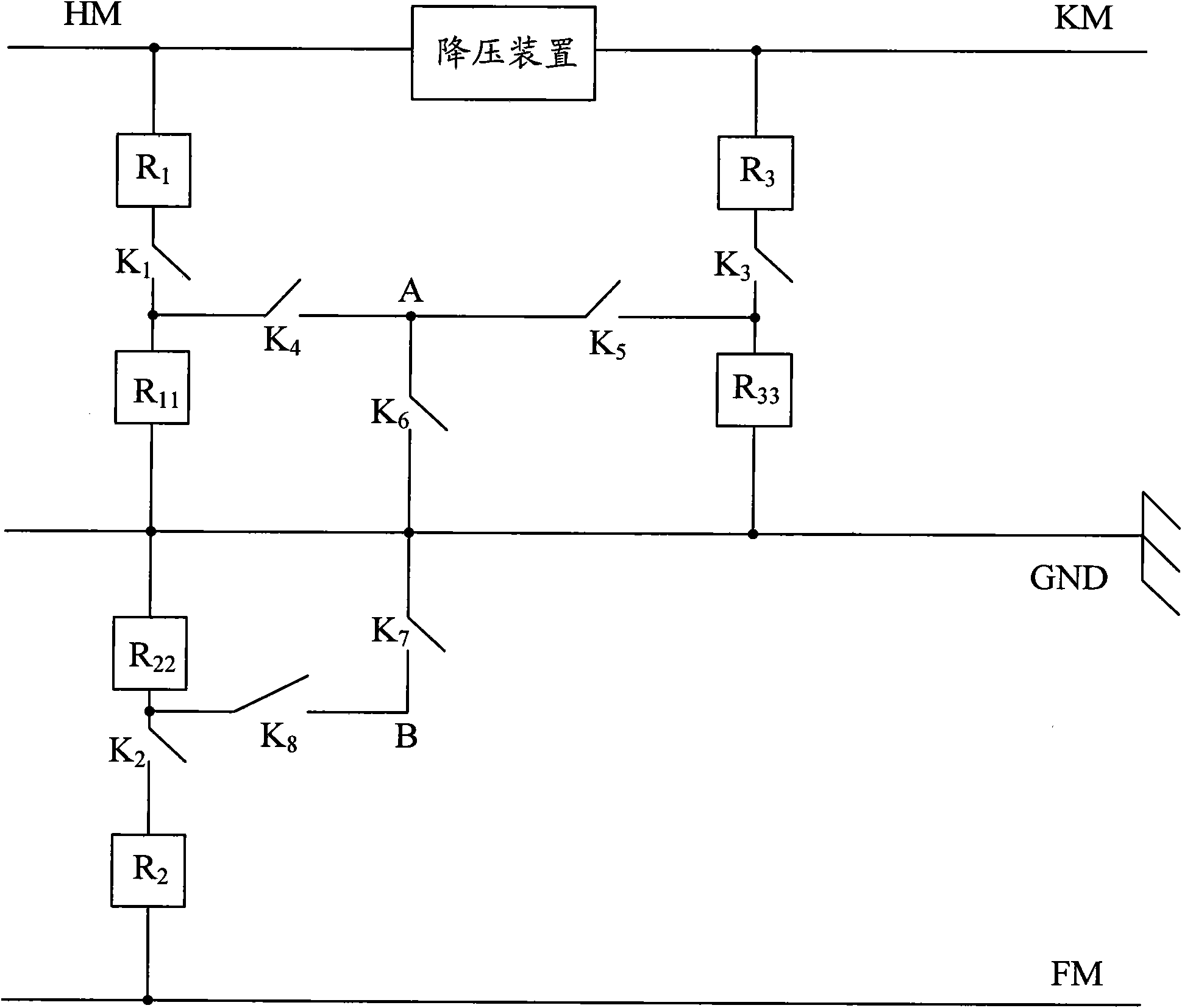

[0086] Step 20: Connect resistor R1, switch K1, and sampling resistor R11 in series from the bus bar HM to the ground line GND, connect the sampling resistor R22, switch K2, and resistor R2 in series from the ground line GND to the bus bar FM, and connect the bus bar KM to the ground A resistor R3, a switch K3 and a sampling resistor R33 are sequentially connected in series in the direction of the line GND. The busbar HM is connected to one end of the switch K1 through the resistor R1, the other end of the switch K1 is respectively connected to one end of the sampling resistor R11 and one end of the switch K4, the other end of the sampling resistor R11 is grounded to GND, and the other end of the switch K4 is respectively connected to the switch through point A. One end of K5 is connected to one end of switch K6, the other end of switch K5 is respectively connected to one end of sampling resistor R33 and one end of switch K3, the other end of sampling resistor R33 is grounded t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com