Engine cooling apparatus

A cooling device and engine technology, which is applied in the cooling of the engine, engine components, machines/engines, etc., can solve the problems of easy knocking, easy cavitation, and reduced water pump pressure, so as to suppress cavitation and knocking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

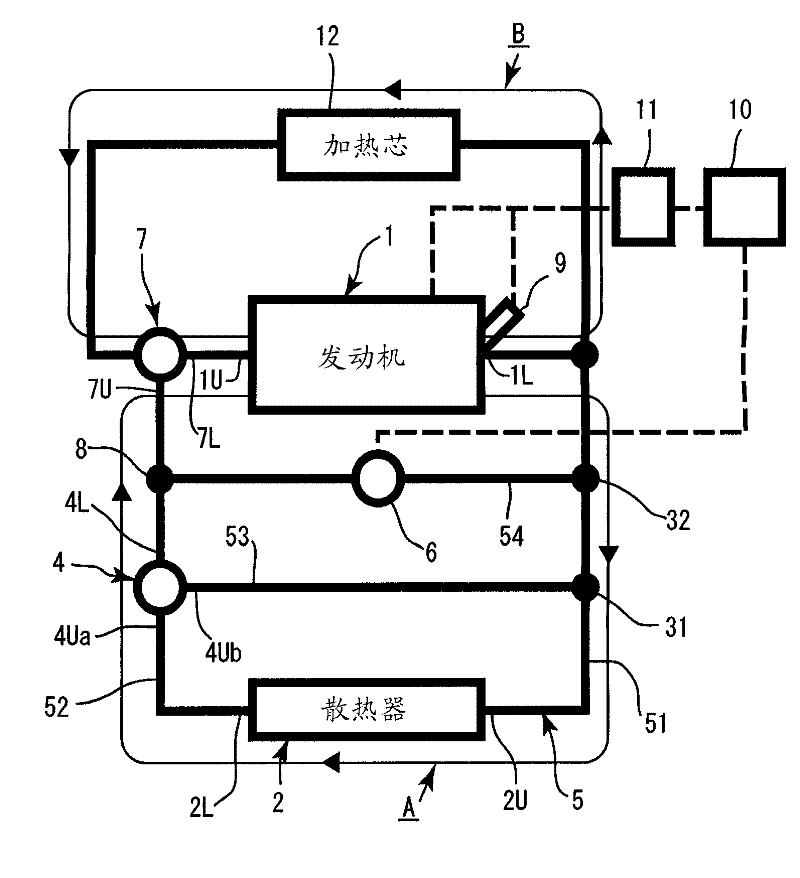

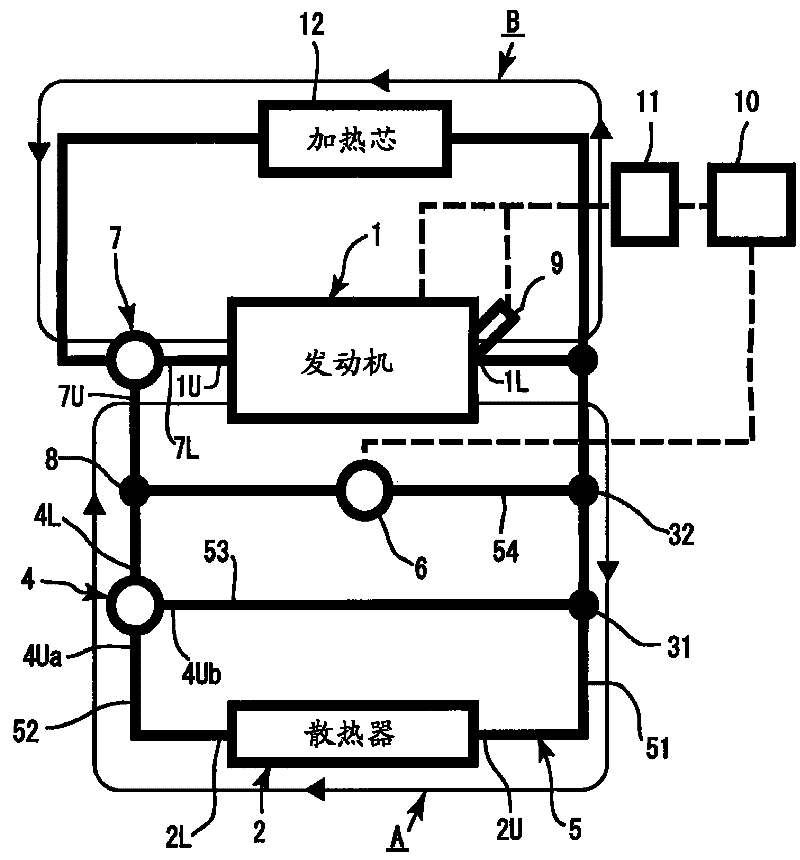

[0020] Embodiments of the present invention will be described below based on the drawings. The present invention is a circuit in which cooling water circulates between the engine 1 and the radiator 2, and is mainly composed of a main cooling water circuit A, a first bypass passage 53, and a second bypass passage 54, and, in addition to these circuits, A heating circuit B having a flow path passing through the engine 1 and a heater core 12 included in the flow path is added together with the main cooling water circuit A described above.

[0021] figure 1 The cooling water circuit of the present invention is shown. Hereinafter, in the description, for parts such as radiator 2 and thermostat 4 in the cooling water circuit, the side where the cooling water flows into the parts is referred to as the upstream side, and "U" is added to the reference numerals of the parts, The side where the cooling water flows out from the part is called the downstream side, and "L" is added to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com