Printing and dyeing sludge pyrolysis treatment device and sludge treatment method

A printing and dyeing sludge and treatment device technology, applied in the field of waste treatment, can solve the problems of industry development constraints, large equipment investment, complex process, etc., and achieve the effects of saving energy, reducing energy consumption, and improving pyrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

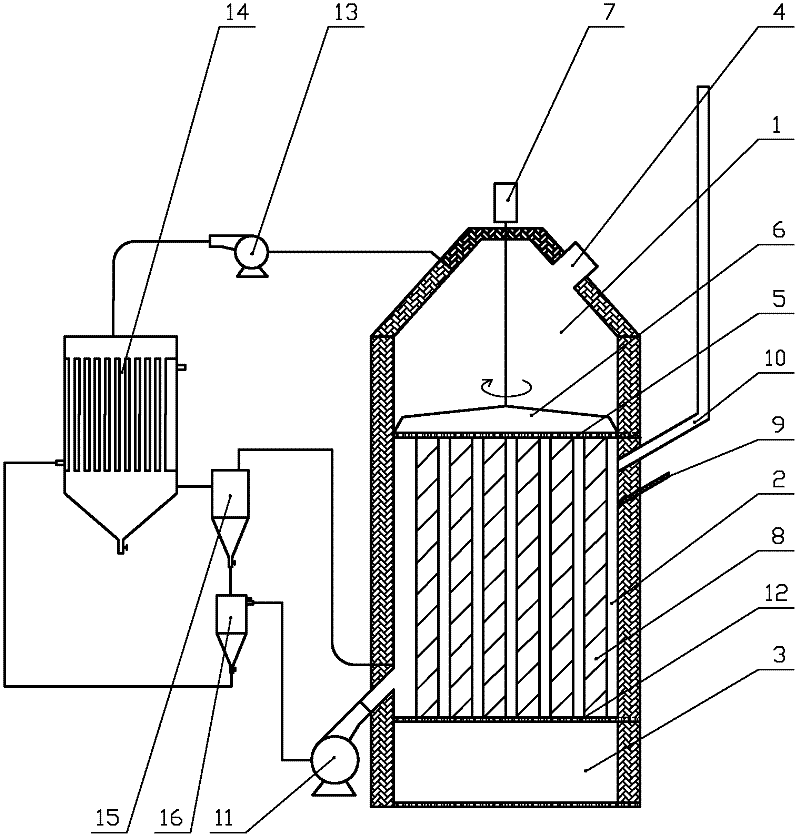

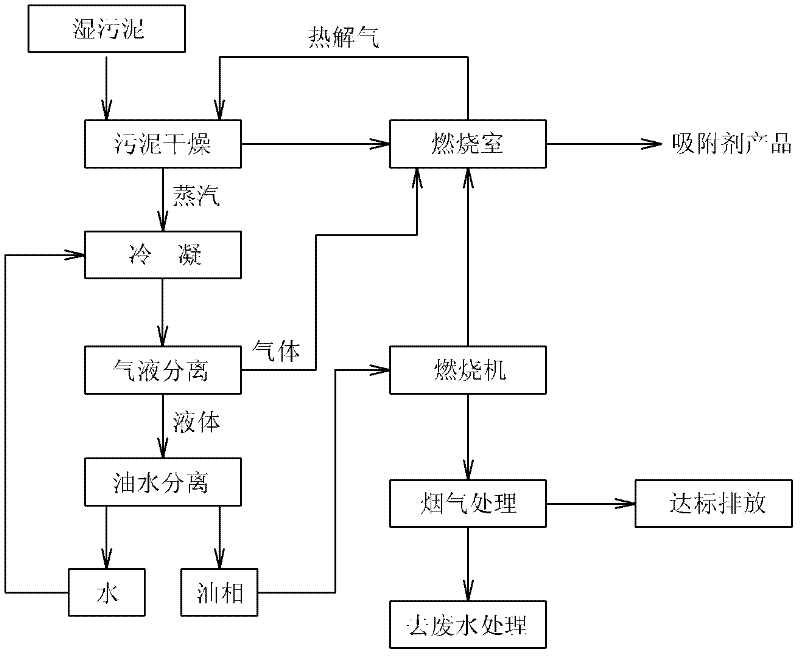

[0034] figure 1 , figure 2 and image 3 Shown is an embodiment of a printing and dyeing sludge pyrolysis treatment device and a sludge treatment method of the present invention. Such as figure 1 and figure 2 As shown, the printing and dyeing sludge pyrolysis treatment device in this embodiment includes a pyrolysis system, waste gas treatment and circulation system.

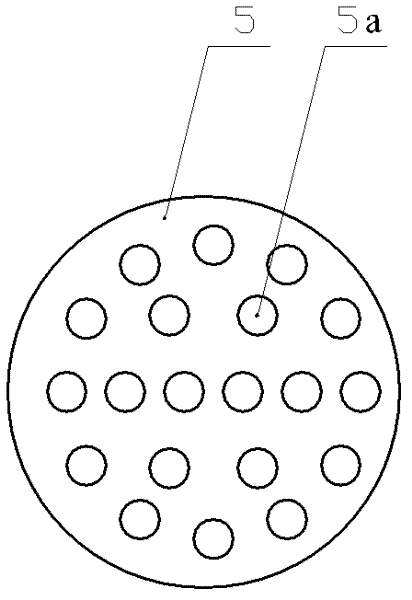

[0035] Such as figure 1 As shown, the pyrolysis system includes a sludge chamber 1, a combustion chamber 2, and a product collection chamber 3 arranged in sequence from top to bottom. Wherein, the sludge chamber 1 is provided with a feed inlet 4, and a support plate 5 with a hole 5a is provided between the sludge chamber 1 and the combustion chamber 2 (see figure 2 ). A rotating plate 6 is arranged above the supporting plate 5 in the sludge chamber 1 and is driven to rotate by a motor 7 . The pyrolysis chamber 8 in the combustion chamber 2 is a plurality of tube-type pyrolysis chambers arranged vertical...

Embodiment 2

[0047] The difference between this example and Example 1 is: the printing and dyeing sludge pyrolysis treatment method in this example, in step (1-b), the sludge is pyrolyzed at a temperature of 500°C for 10 minutes; in step (2-b) The mixed gas is cooled to 50° C. through the condenser 14 and enters the gas-liquid separator 15 to stay for 1 minute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com