Pneumatic lifting material frame

A pneumatic lifting and material racking technology, applied in the field of lifting racks, can solve the problems of inconvenient operation, time-consuming and laborious, etc., and achieve the effect of wide application range, convenient use, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

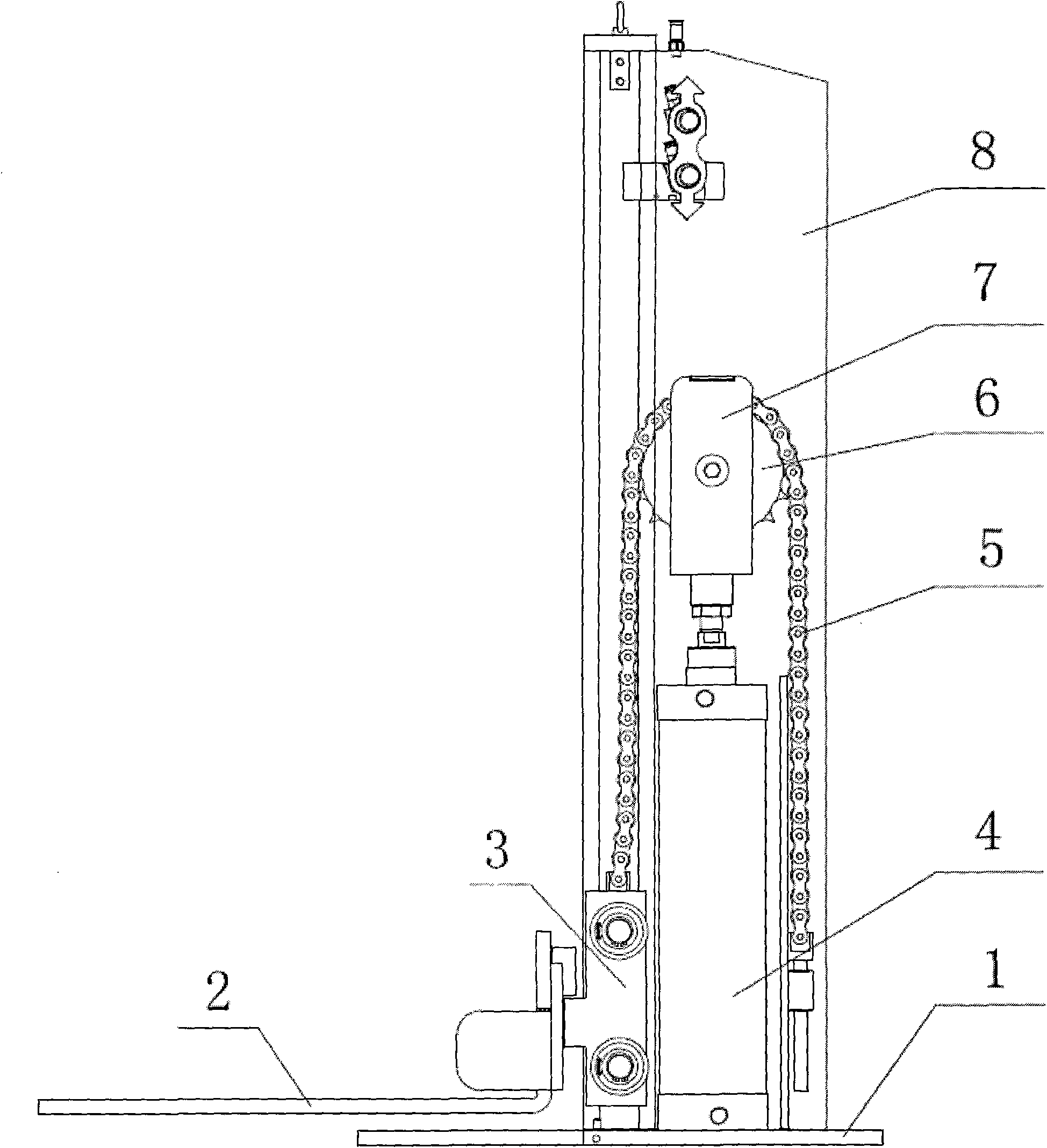

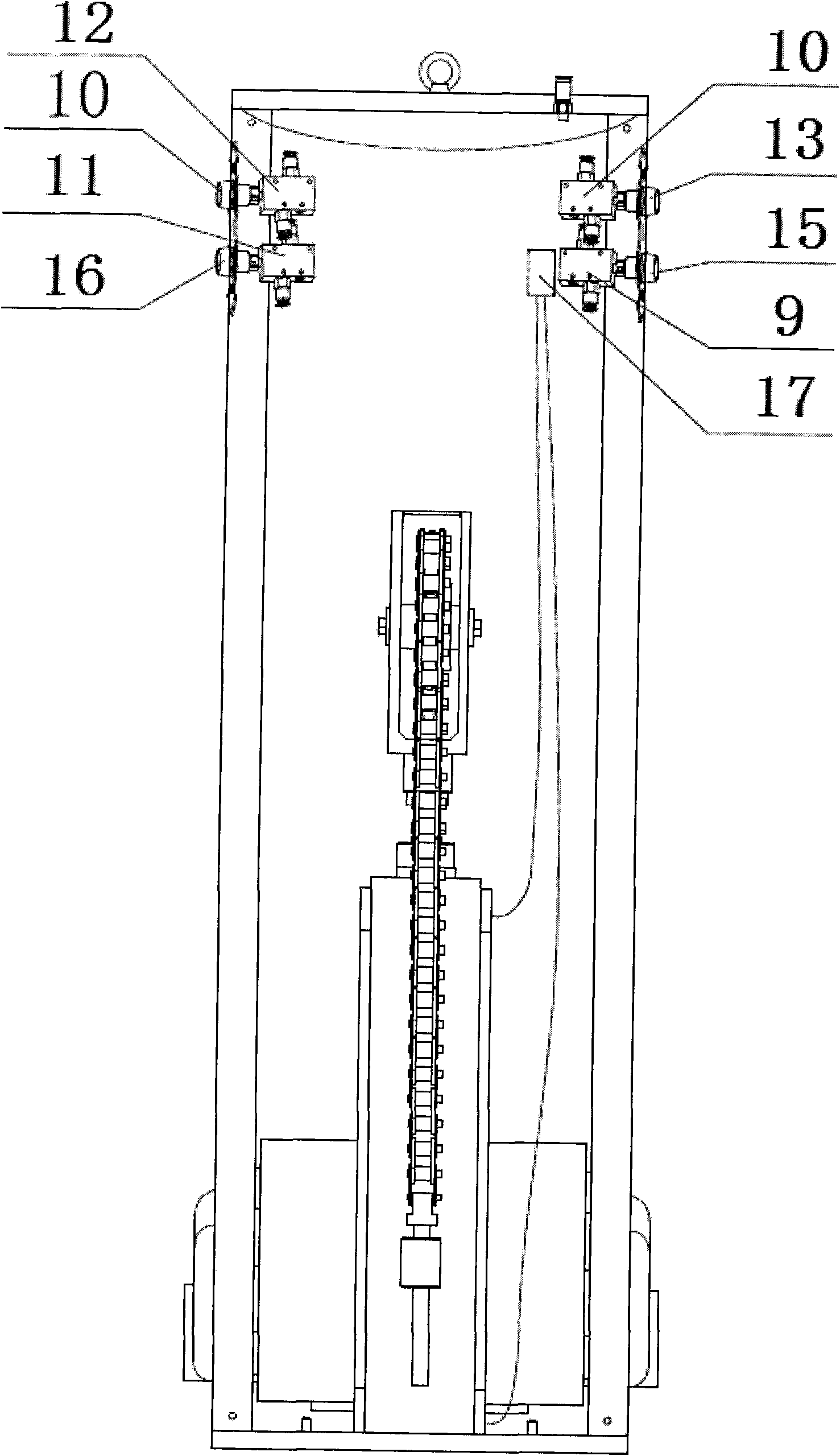

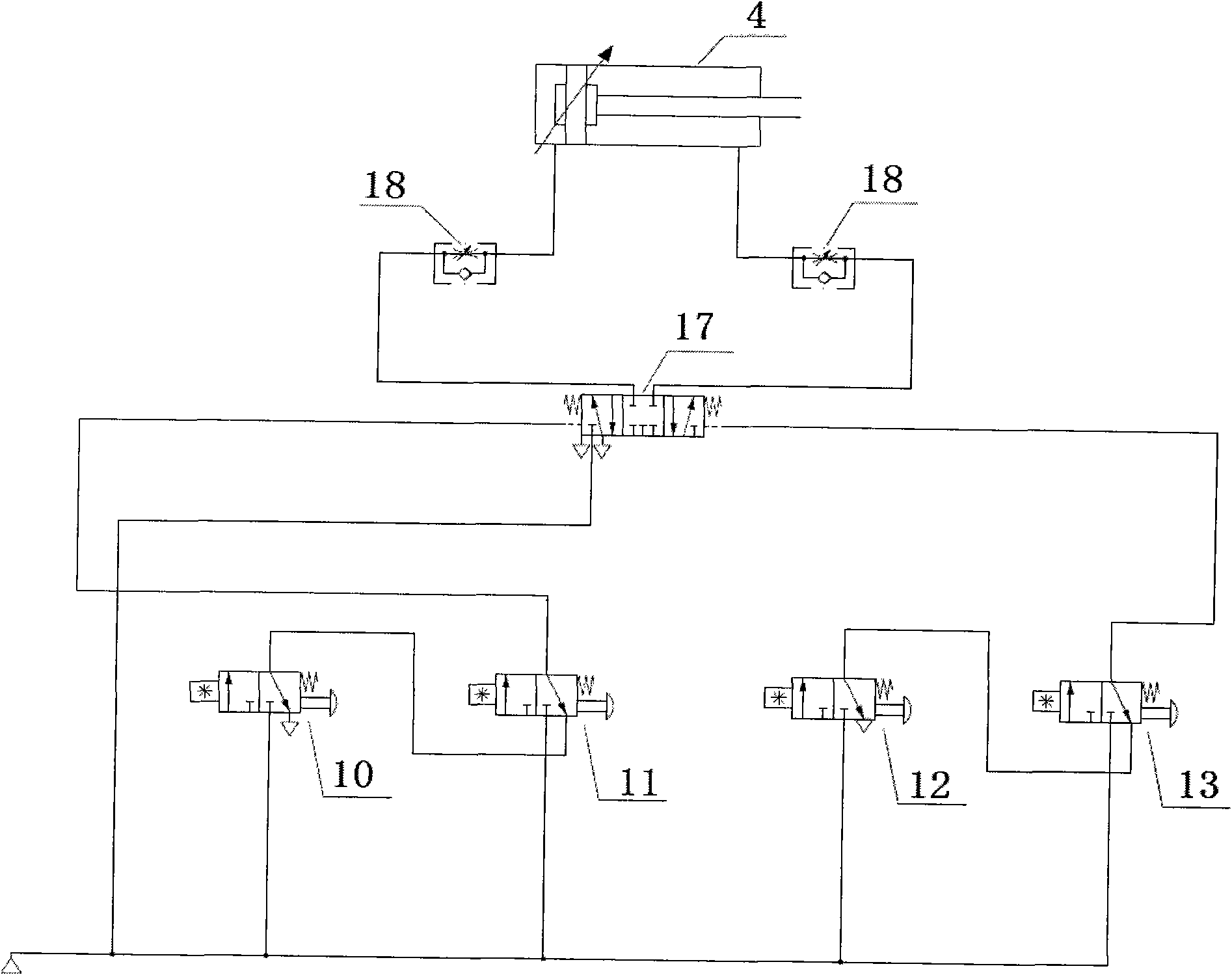

[0020] Such as Figure 1-3 As shown, a pneumatic lifting material rack includes a mechanical part and a pneumatic device, and the mechanical part includes a fixed frame 1, a lifting foot 2, a lifting foot mounting seat 3, an upper connecting frame, a sprocket 6, Sprocket mounting seat 7, chain 5, bearing, front panel and rear panel 8, the lifting foot 2 is arranged on the lifting foot mounting seat 3, which can be easily disassembled, and the lifting foot mounting seat 3 is arranged on the fixed frame 1 Above, the upper connecting frame is arranged on the fixed frame 1, and the front panel and the rear panel 8 are respectively arranged on the front and the back of the pneumatic lifting material rack; the pneumatic device includes a cylinder 4, an air control valve 17, The first switch valve 9, the second switch valve 10, the third switch valve 11, the fourth switch valve 12, the first up switch button 13, the second up switch button 14, the first down switch button 15, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com