Hub reduction device for mining dump truck with electric wheels

A mining dump truck and wheel-side deceleration technology, which is applied in the field of wheel-side deceleration, can solve the problems of unreasonable structure design of the wheel-side reducer, increased power consumption and cost of the whole vehicle, low safety and reliability, etc., and achieves the goal of providing The effect of safety and reliability, reasonable structure and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

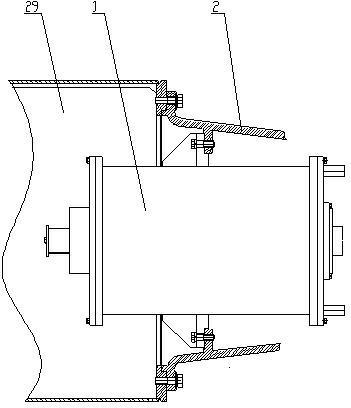

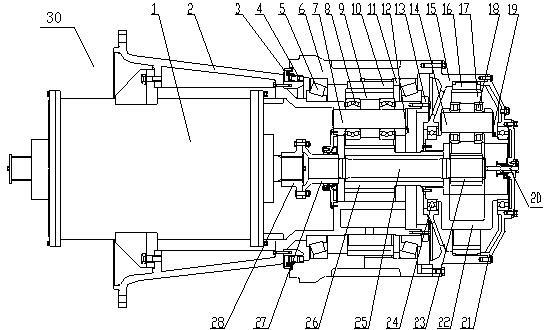

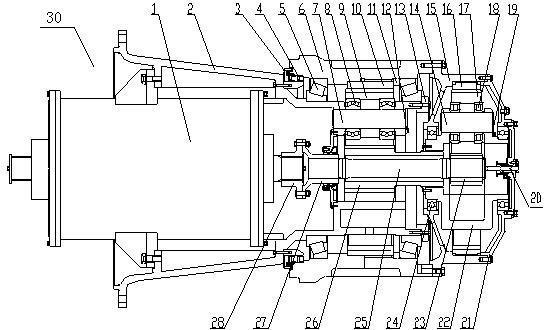

[0018] Such as figure 1 with figure 2 As shown, a wheel side reduction device of an electric wheel mining dump truck includes a main body 30, a driving motor 1, a secondary planetary carrier 2, a retaining ring I3, a sealing ring 4, a bearing I5, a wheel hub 6, and a secondary planetary shaft 7 , Bearing Ⅱ8, secondary planetary wheel 9, secondary internal gear 10, spacer 11, axle baffle Ⅰ12, retaining ring Ⅱ13, primary planetary shaft 14, end cover 15, primary internal gear 16, primary planet Wheel 17, bearing III 18, axle baffle II 19, respirator 20, outer end cover 21, first-level planet carrier 22, first-level sun gear 23, bearing IV 24, half shaft 25, connecting shaft 26, half shaft flange 27 and The motor shaft flange 28, wherein the gear mechanism of the main body 30 is composed of a half shaft 25, a primary sun gear 23, a primary planetary gear 17, a primary inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com