Tower type cell carrying table

A technology of cell and carrying platform, which is applied to workbenches, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of large floor space, cannot be stacked, time-consuming and labor-intensive, etc., to improve production efficiency, save site space, The effect of reducing the retrieval time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

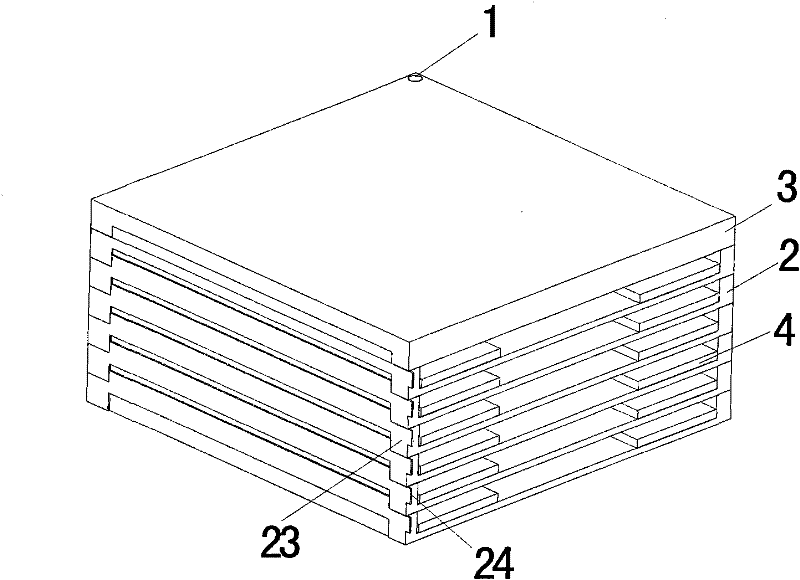

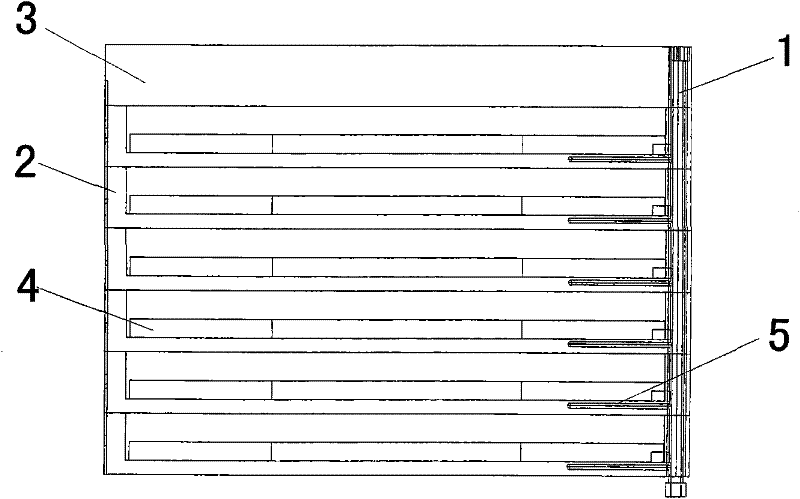

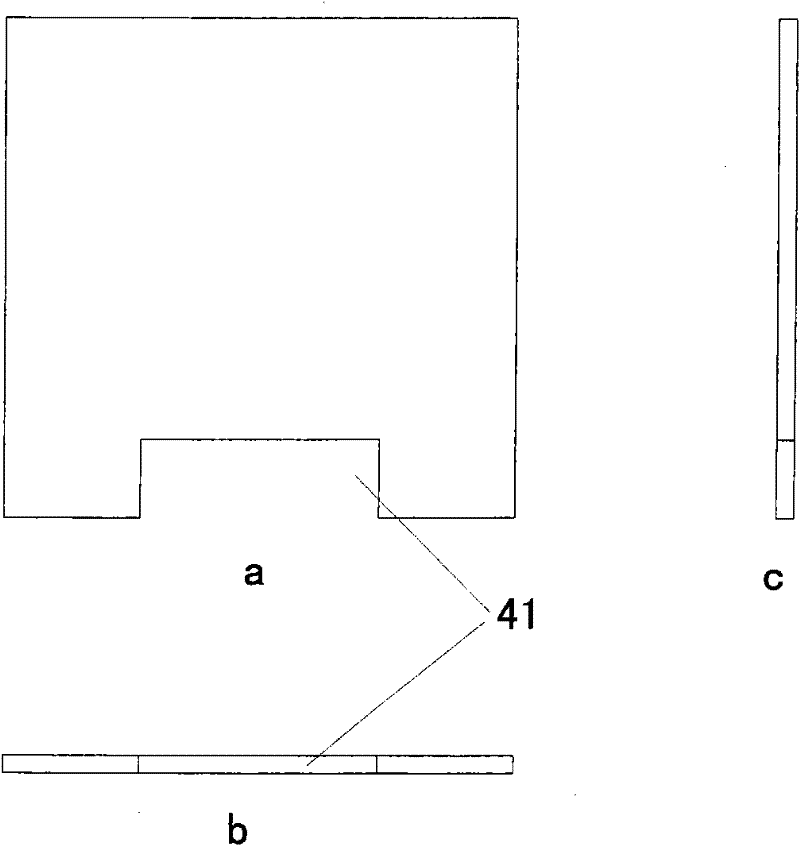

[0019] see figure 1 , with reference to figure 2 , image 3 , Figure 4 , Figure 5 . The tower-type battery chip supporting platform of the present invention includes a vertical shaft 1 , a plurality of rotating flat plates 2 , a top plate 3 , a plurality of supporting plates 4 and a plurality of dowel bars 5 . A plurality of rotating flat plates 2 are installed in layers on the vertical shaft 1 and can rotate around the vertical shaft respectively. The top plate 3 is arranged above the plurality of rotating flat plates 2 and is fixedly connected with the vertical shaft 1 . A plurality of bearing plates 4 are respectively nested in each rotating flat plate 3 . A plurality of dowel bars 5 are respectively fixedly installed on the vertical shaft corresponding to the plurality of bearing plates 4 , and can push out the corresponding bearing plates when the corresponding rotating flat plate 2 rotates.

[0020] Cooperate see Figure 4 The rotary plate 2 in the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com