Application of compatible solute to fermentation of high-salinity dilute soy sauce

A technology of high-salt dilute soy sauce and high-salt dilute state, which is applied in the field of fermentation to achieve the effect of protection, balance of osmotic pressure inside and outside cells, and improvement of metabolic capacity or enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

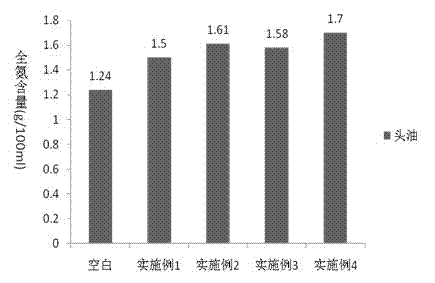

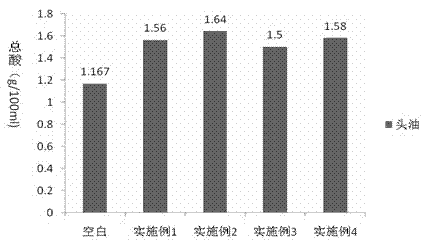

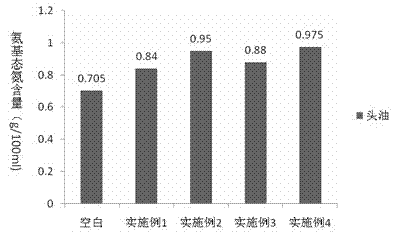

Embodiment 1

[0031] Make koji according to the conventional method, then mix the finished koji with salt water (18%, w / v) at a ratio of 1:2.3, and then put it into the tank for fermentation; Afterwards, it is oiled once a day for 10 consecutive days, and then salted and fermented. When the natural fermentation reaches the national standard, the head oil is filtered out. A certain sample was taken to detect its total acid content, amino nitrogen content and total nitrogen content.

Embodiment 2

[0033] Make koji according to the conventional method, then mix evenly with salt water (18%, w / v) in a ratio of 1: 2.3 and then go up to the tank for fermentation; when going up the tank, artificially add 0.2% of mass fraction of glycine betaine and 0.2% of mass fraction % of salt-tolerant lactic acid bacteria suspension, the final concentration of salt-tolerant lactic acid bacteria is 10 5 More than cfu / ml; Drain the oil once a day after being put into the tank, and then salt-sealing and ferment after 10 days of continuous oil drenching; when the physical and chemical indicators of natural fermentation reach the national standard, filter out the head oil. A certain sample was taken to detect its total acid content, amino nitrogen content and total nitrogen content.

Embodiment 3

[0035] Make koji according to the conventional method, mix the koji and salt water (18%, w / v) in a ratio of 1: 2.3, and then put it on the tank for fermentation; when putting it on the tank, artificially add glycerin with a mass fraction of 0.3%; Oil once, pour oil continuously for 10 days, then salt seal and ferment. When the natural fermentation reaches the national standard, the head oil is filtered out. A certain sample was taken to detect its total acid content, amino nitrogen content and total nitrogen content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com