Liquid applicator vessel

A liquid material and delivery technology, which is applied in household containers, cosmetic containers, cosmetic powder containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described below with reference to the drawings.

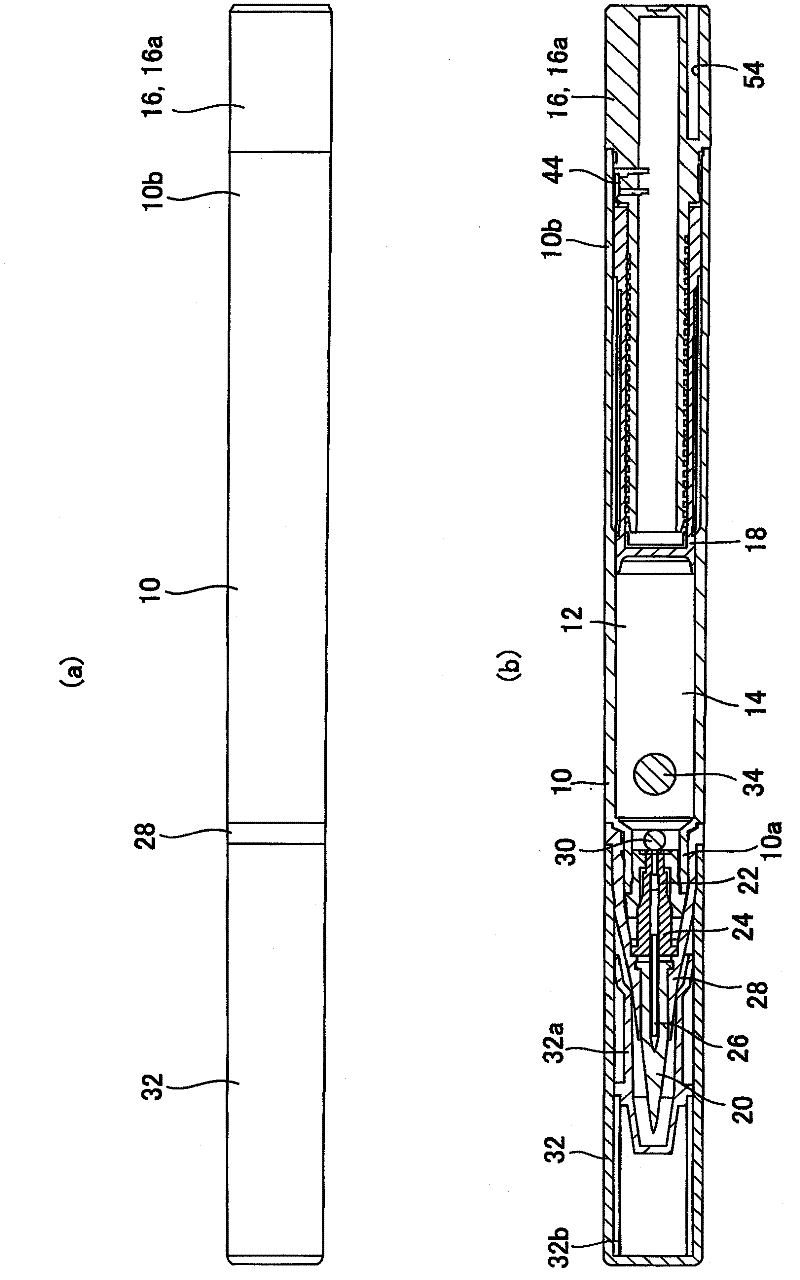

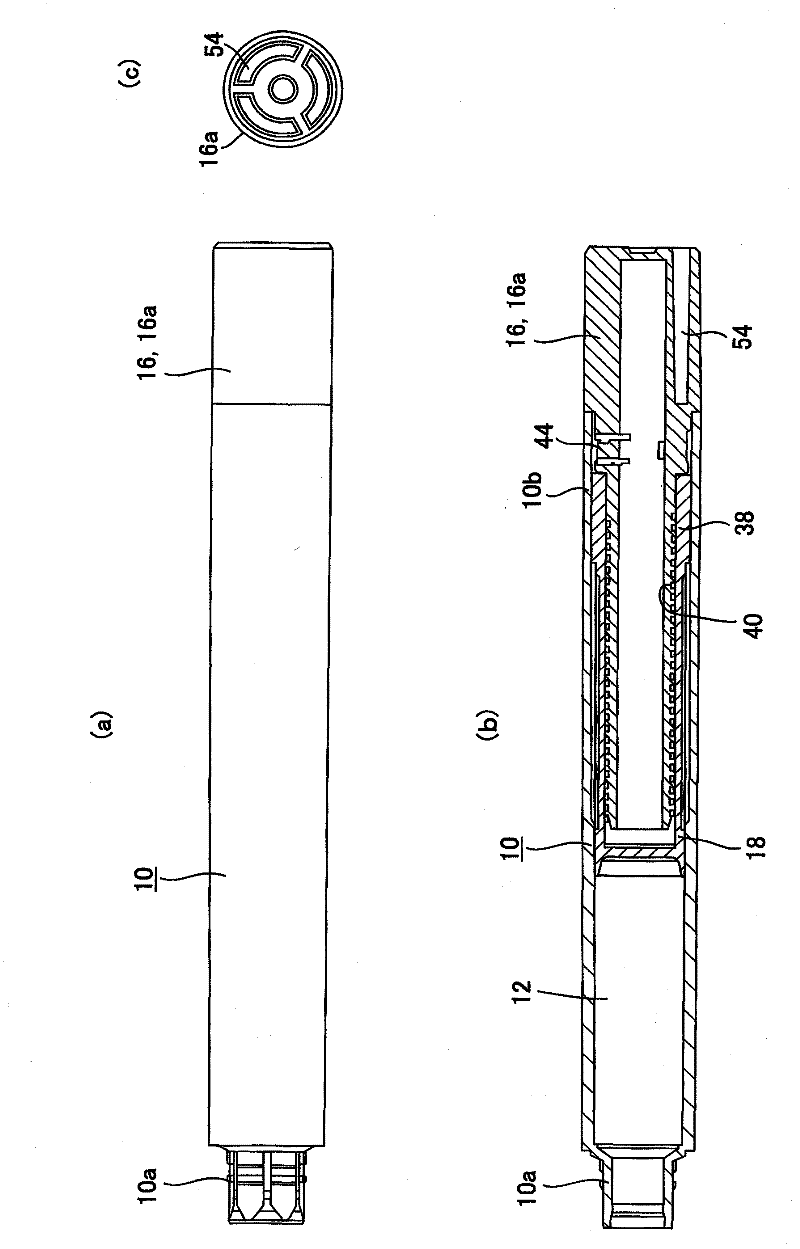

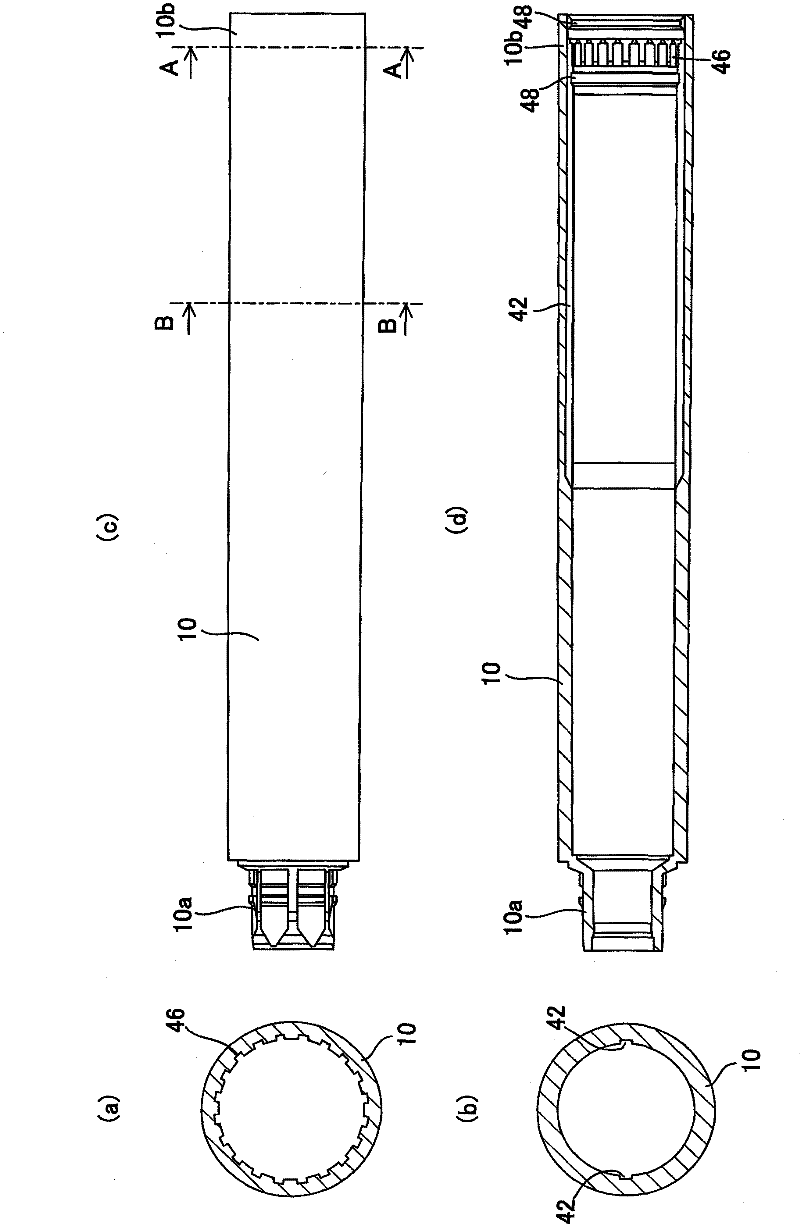

[0032] Figure 1 to Figure 5 are explanatory diagrams of the liquid material feeding container according to the embodiment of the present invention, and in these drawings, parts assigned the same reference numerals denote the same components.

[0033] Such as figure 1 and figure 2 As shown, the liquid feeding container of the present embodiment is a liquid material feeding container as follows: the liquid content 14 is accommodated in the storage portion 12 provided on the cartridge body 10, and the rotating member 16 is rotated from the rear end of the cartridge body 10 The operating part 16a exposed from the part 10b rotates relative to the cylinder body 10 to advance the piston 18 in the storage part 12 and feed the content 14 to the front of the cylinder body 10. The liquid material feeding container is composed of three parts, namely: Cartridge body 10 , rotating eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com