Novel device for measuring flow of pump station

A flow measurement device and pumping station technology, which is applied in the direction of detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., can solve problems such as difficult operation, poor precision, and complicated operation, and achieve high measurement accuracy, Easy to make, easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

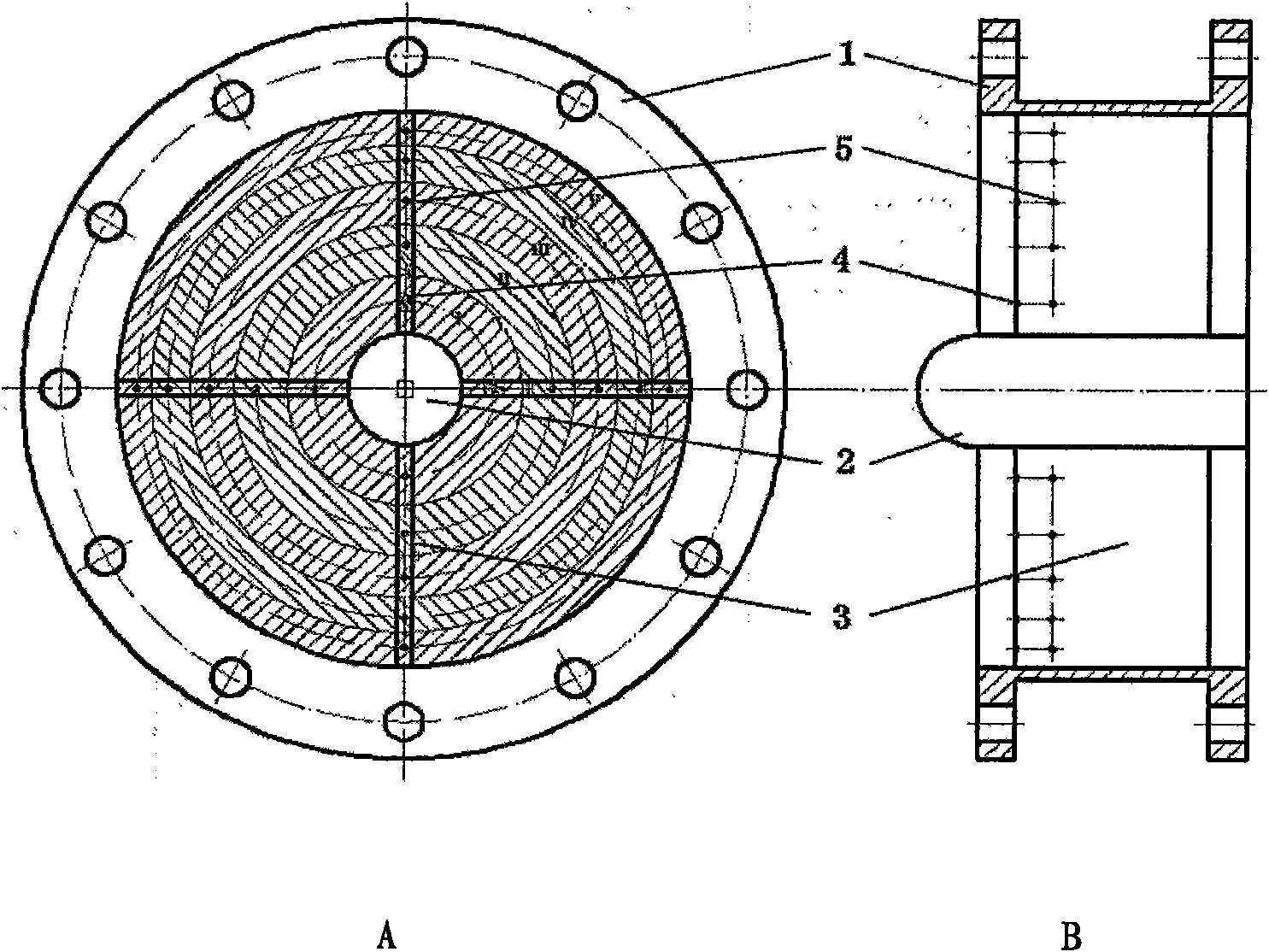

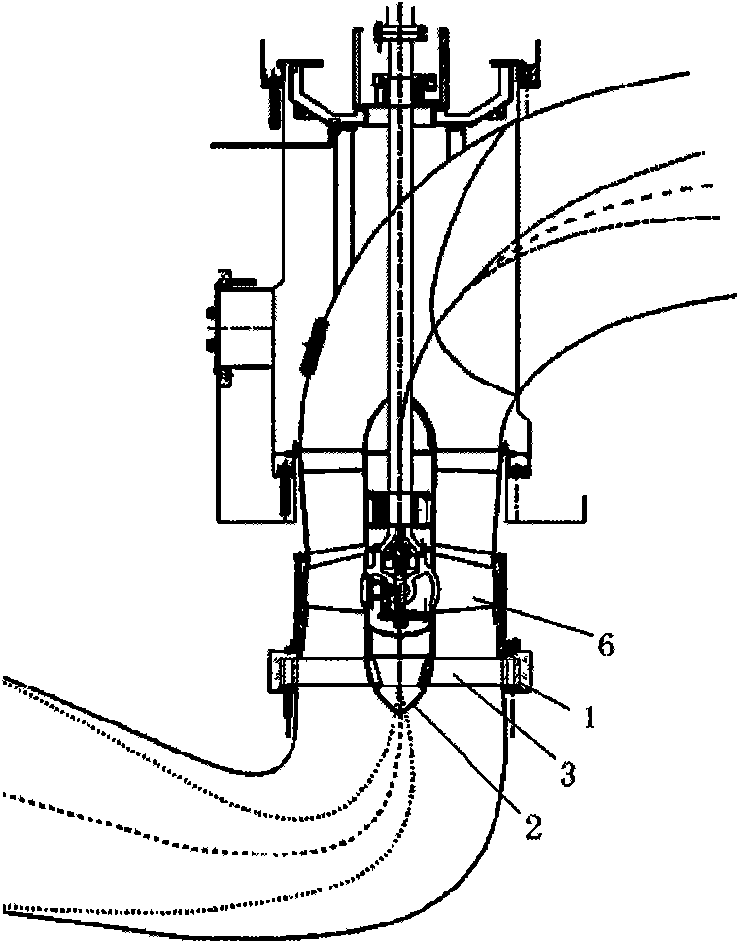

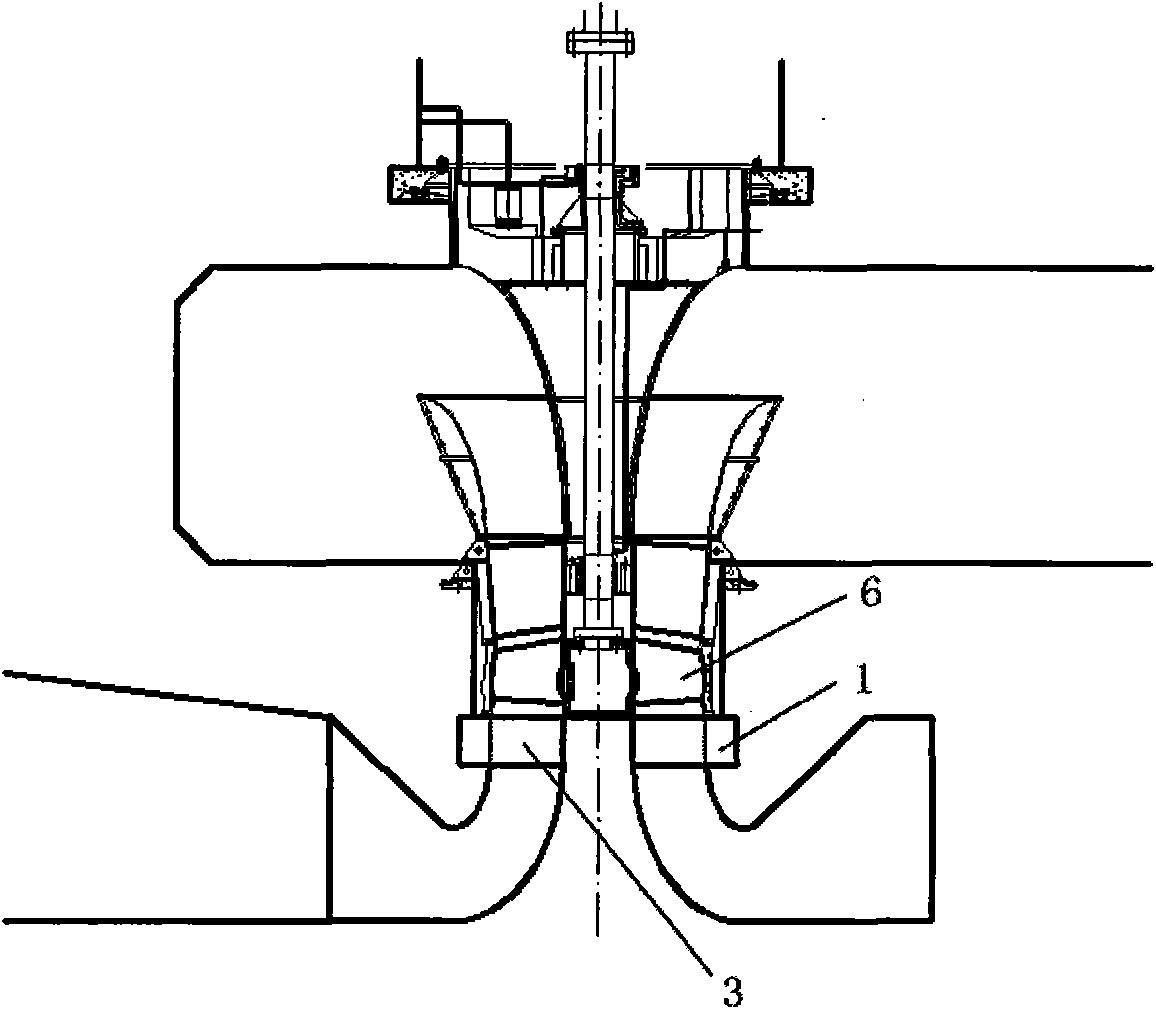

[0013] like figure 1 (A, B), figure 2 , image 3 and Figure 4 Shown:

[0014] The flow measuring device is composed of flow measuring vanes 3 , hub 2 and seat ring 1 . The hub 2 is located at the center of the seat ring 1, and four flow-measuring blades 3 arranged vertically and symmetrically connect the seat ring 1 and the hub 2, as shown in figure 1 As shown in (A), it is installed in front of the water pump impeller 6 inlet as a whole through the outer seat ring 1 (in figure 2 , image 3 In the shown vertical unit, the flow measuring device is located at the lower part of the impeller 6); according to the principle of equal flow, the water flow section where the flow measuring device is located is divided into 3 to 5 adjacent flow rings, in this example, 4 phase flow rings Adjacent flow rings; each flow ring has a cross-section surface with the water-facing front of the flow-measuring blade 3, and the center of the cross-section surface is facing the direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com