Method for processing suspension top by medium-deep hole blasting on upper and lower shoes

A deep hole blasting and deep hole technology, which is applied in earth drilling, underground mining, surface mining, etc., can solve problems such as inaccurate drawings, dangers, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

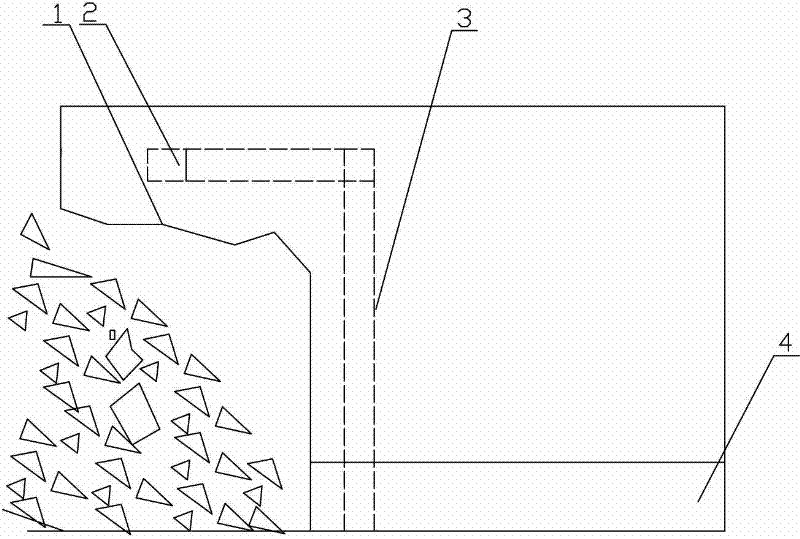

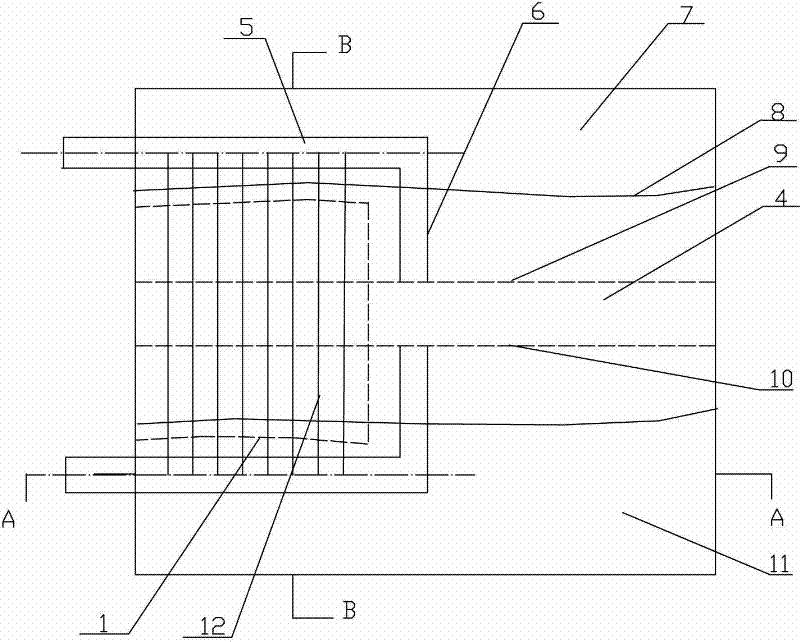

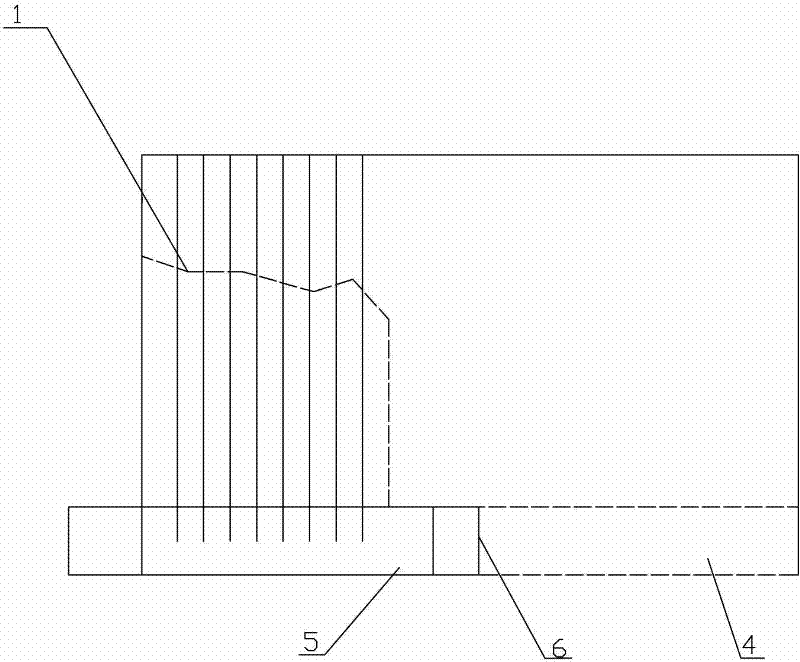

[0012] like figure 2 , image 3 , Figure 4 Shown: the method for treating the suspended roof by medium-deep hole blasting of the upper and lower sides of the present invention is characterized in that two rock-drilling joint roadways are vertically pierced through the veins at the same time on the upper side of the roadway and the lower side of the roadway of the electric shovel out of the mine roadway. After the rock-drilling roadway passes through the vein, two medium-deep-hole rock-drilling roadways are drilled in parallel with the electric shovel exit roadway in the direction of the overhanging top position, and are vertically connected with the rock-drilling roadway. The rock roadway is excavated beyond the overhanging top, and then in the two rock drilling roadways, the middle and deep hole construction is carried out to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com