Method for reducing minimum miscible phase pressure between CO2 and crude oil of miscible phase displacement

A technology of miscible pressure and miscible flooding, which is applied in the new field of CO2 miscible flooding in oil reservoirs, can solve the problems of reducing the minimum miscible pressure, high minimum miscible pressure, inability to realize miscible flooding, etc., and achieves lower minimum miscible pressure and low cost. , the effect of high recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 50g of high waxy crude oil with a viscosity of 20.9mPa·s at 50°C, add 0.3% isoamyl citrate to it, stir and mix thoroughly, measure its viscosity at 50°C as 9.3mPa·s, and the viscosity reduction rate is 55.5% %. It shows that isoamyl citrate has a good viscosity-reducing effect on high waxy crude oil.

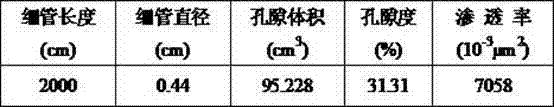

[0020] According to the experimental procedures stipulated in the petroleum industry standard "SY / T 6573-2003", the crude oil sample was first tested for pure CO at a temperature of 85°C and a pressure of 22.64MPa. 2 According to the displacement experiment, the recovery rate was measured to be 76.90%; then the narrow tube was cleaned according to the experimental procedures stipulated in the standard; The sample will saturate the thin tube; after saturation, 0.3% (according to the surfactant in supercritical CO 2 Calculation of the mass concentration in, CO under 22.64MPa 2 The total injected volume is 1.2 pore volume, which is 114.274cm 3 ) of isoamyl citrate i...

Embodiment 2

[0023] Take 50g of highly waxy crude oil with a viscosity of 20.6mPa·s at 50°C, add 0.3% isoamyl citrate to it, stir and mix thoroughly, measure its viscosity at 50°C as 8.8mPa·s, and the viscosity reduction rate is 57.28 %.

[0024] According to the experimental procedures stipulated in the petroleum industry standard "SY / T 6573-2003", the crude oil sample was first tested for pure CO at a temperature of 85°C and a pressure of 18MPa. 2 According to the displacement experiment, the recovery rate was measured to be 66.60%; then the narrow tube was cleaned according to the experimental procedures stipulated in the standard; The crude oil sample will saturate the thin tube; after saturation, 0.3% (according to the surfactant in supercritical CO 2 Calculation of mass concentration in CO2 at 18MPa 2 The total injected volume is 1.2 pore volume, which is 114.274cm 3) of isoamyl citrate is injected into the thin tube at a pressure of 18MPa, and finally according to the experimenta...

Embodiment 3

[0027] 50 g of the same crude oil as in Example 1 was added with 0.2% isobutyl citrate, fully stirred and mixed, and the viscosity at 50° C. was determined to be 8.6 mPa·s, and the viscosity reduction rate was 58.9%. It shows that isobutyl citrate has a good viscosity-reducing effect on high waxy crude oil.

[0028] According to the experimental procedures stipulated in the petroleum industry standard "SY / T 6573-2003", the crude oil sample was first tested for pure CO at a temperature of 85°C and a pressure of 22.64MPa. 2 According to the displacement experiment, the recovery rate was measured to be 76.90%; then the narrow tube was cleaned according to the experimental procedures stipulated in the standard; The sample will saturate the thin tube; after saturation, 0.2% (according to the surfactant in supercritical CO 2 Calculation of the mass concentration in, CO under 22.64MPa 2 The total injected volume is 1.2 pore volume, which is 114.274cm 3 ) of isobutyl citrate is inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com