Granite concrete pavior brick and its manufacturing method

A technology of concrete pavement and production method, which is applied in the field of pavement brick building materials, can solve the problems of unsatisfactory use effect, poor drainage performance, poor wear resistance, etc., and achieve reduced maintenance work, beautiful surface without reflection, and stress-resistant uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below, the present invention will be further described in conjunction with the accompanying drawings and embodiments.

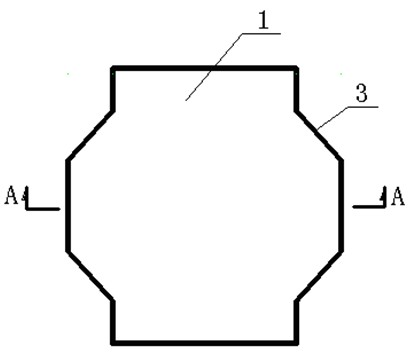

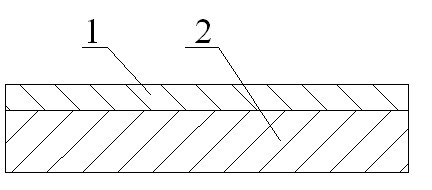

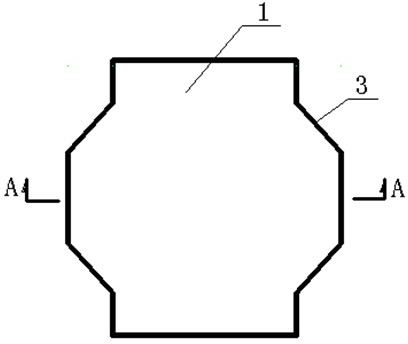

[0015] Embodiments of the present invention: when making the granite concrete pavement brick of the present invention, the granite concrete pavement brick is made into a surface layer 1 mixed with cement, mountain sand and granite as raw materials and made of cement, mountain sand, crushed stone The bottom layer 2 is composed of raw materials mixed together (such as figure 2 shown), and the surface layer 1 and the bottom layer 2 are pressed into one body by pressing, and the shape is pressed into a lantern shape composed of a cross shape and a reinforced inclined block edge 3 (such as figure 1 As shown), that is, every two adjacent right-angled sides of the cross are connected with reinforced inclined block sides 3; during production, the thickness B1 of the surface layer 1 can be controlled in the range of 3mm to 8mm according to the needs of use, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com