Novel electronic bar tacking machine

A kind of tacking machine and electronic technology, which is applied in the direction of cloth pressing mechanism, sewing machine components, sewing machine control devices, etc., can solve the problems of rough wiring, troublesome users, resumption of work, etc., and achieve simple and scientific structure, beautiful wiring, and less faults Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

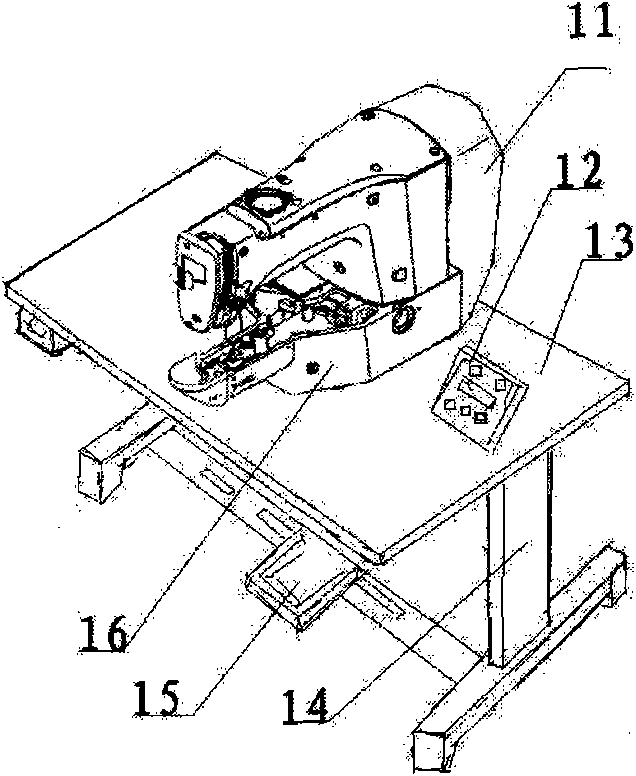

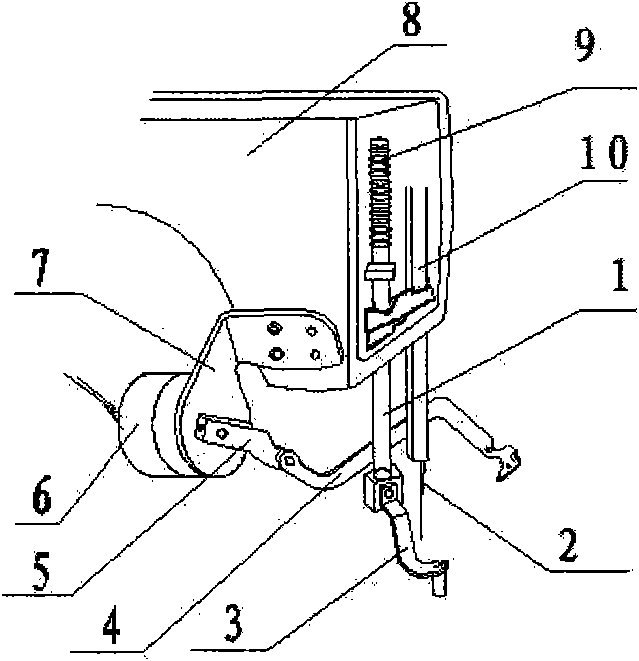

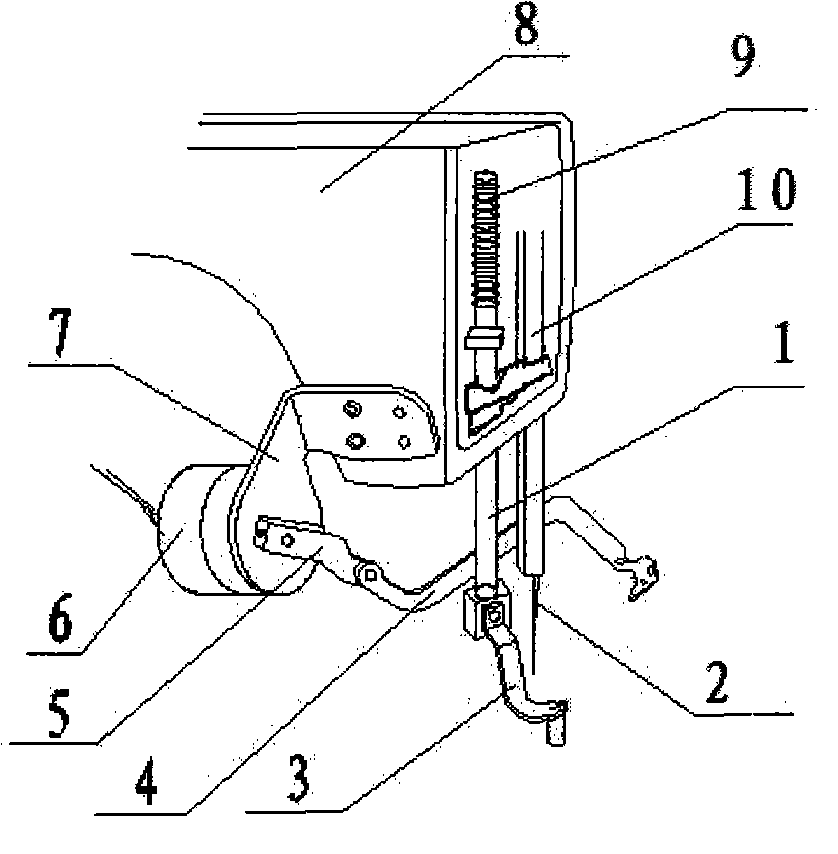

[0010] according to figure 1 , 2 As shown, the invention provides a novel electronic tacking machine, which consists of a presser foot rod 1, a needle 2, a fixed cloth presser foot 3, a thread thrower 4, a thread thrower connecting rod 5, an electromagnet 6, and an electromagnet mounting plate 7 , casing 8, spring 9, needle bar 10, back cover 11, touch screen 12, platen 13, frame 14, pedal 15, support 16 and form. Platen 13 is arranged on the frame 14, machine base 16, touch screen 12 are fixed on the platen 13, pedal 15 is located at the bottom of platen 13, back cover 11 is covered on the tacking machine, presser foot structure is formed by presser foot 3 Composed of presser foot rod 1, presser foot rod 1 is cylindrical, vertically installed in the casing 8, parallel to the needle bar 10 structure, the upper end is equipped with a return spring 9, and the presser foot structure is connected with the guide block of the needle bar structure in the middle , the presser foot 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com