Method for comprehensively utilizing water in ammonium sulfate production

An ammonium sulfate and reclaimed water technology, applied in ammonium sulfate, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of large water consumption, difficulty, environmental pollution, etc., to improve the utilization rate of ammonia nitrogen, eliminate the Pollution source, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

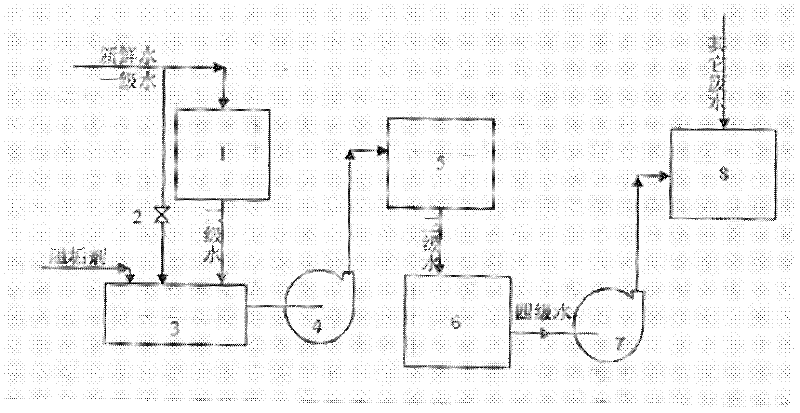

[0010] Example: The Phosphate Fertilizer Plant of Wengfu (Group) Co., Ltd. uses phosphogypsum as raw material to produce ammonium sulfate. According to the difference in water quality, water is used rationally according to the principle of high-quality water for high use and low-quality water for low use.

[0011] Fresh water is used as water for vacuum pump 1. The water used by vacuum pump 1 is collected in collection tank 3. Different amounts of scale inhibitors are added according to different water quality. 4. After pressurization, it is used as sealing water of each machine pump 5, and the sealing water of machine pump 5 is directly discharged into the circulating water tank 6 through the pipeline, and the circulating water and other waste water are sent to the filter 8 through the pipeline as washing water.

[0012] The device reduces the consumption of fresh water through the cascade utilization of water, and the consumption of fresh water is reduced to about 60t / h, savi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com