Pressing fixture

A technology of pressing fixtures and pressing parts, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of large manpower consumption, reduced reliability of LED bulb products, and increased production cost of solid-state light source bulbs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution will be further described in detail below in conjunction with the accompanying drawings and embodiments.

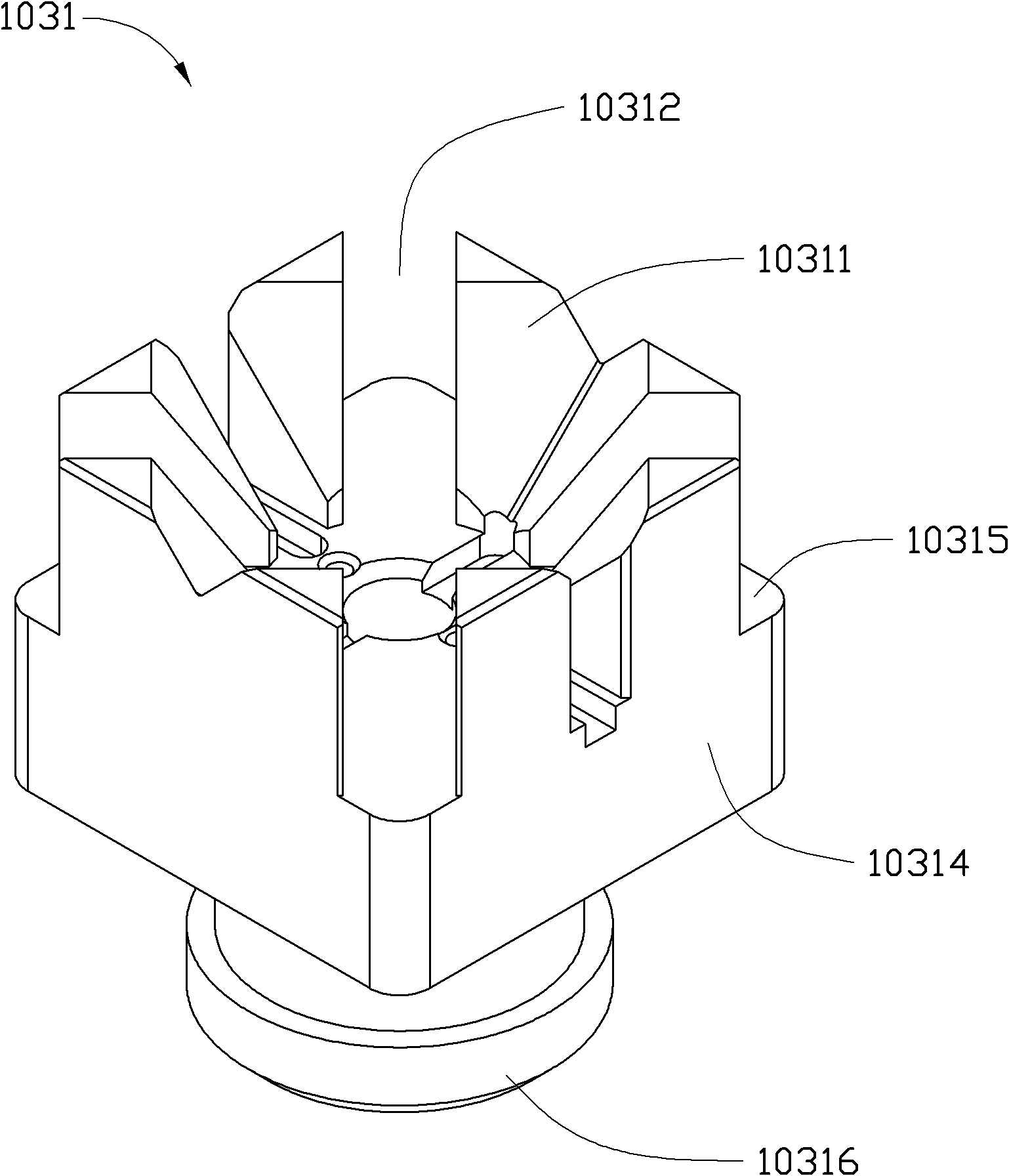

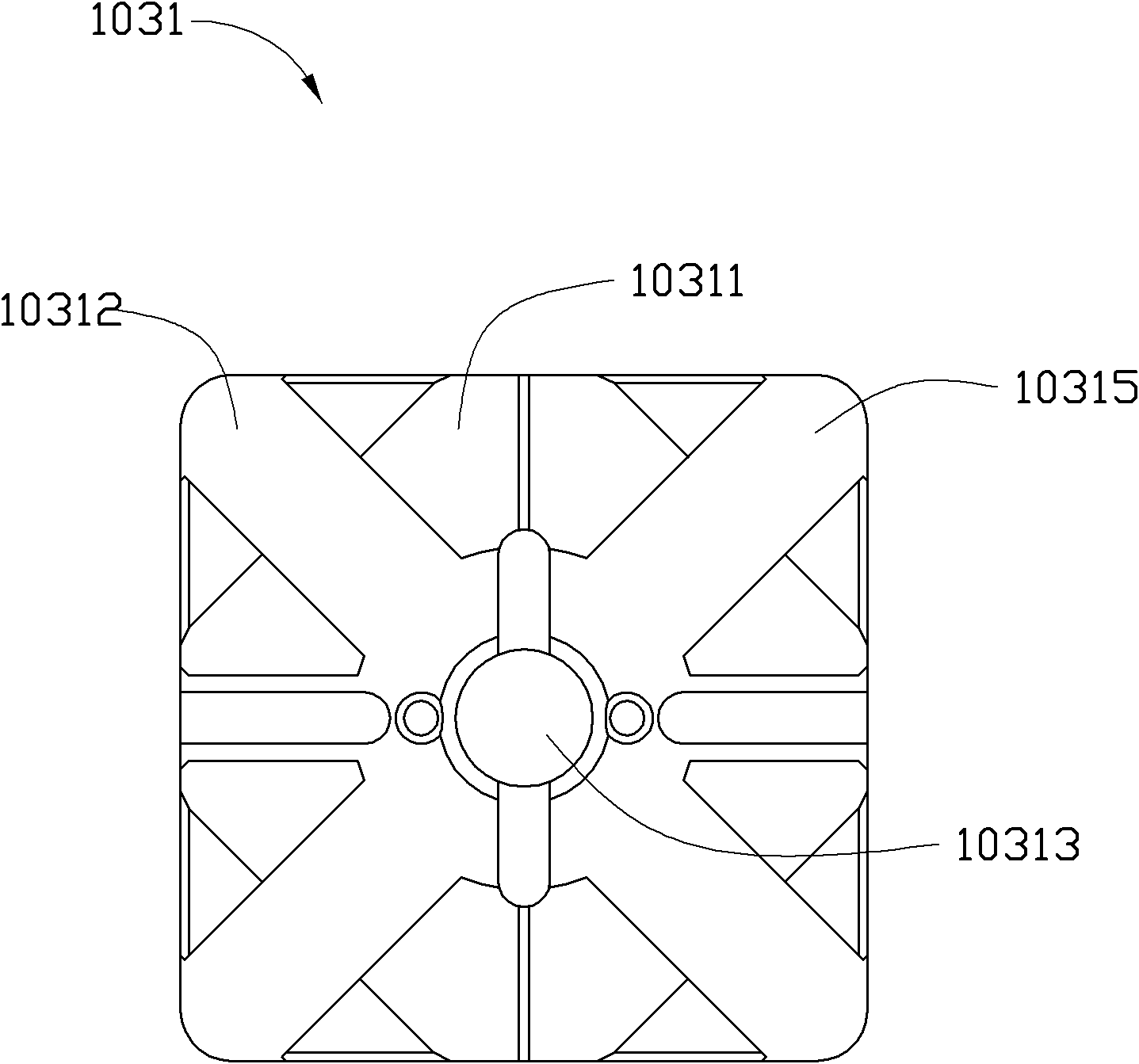

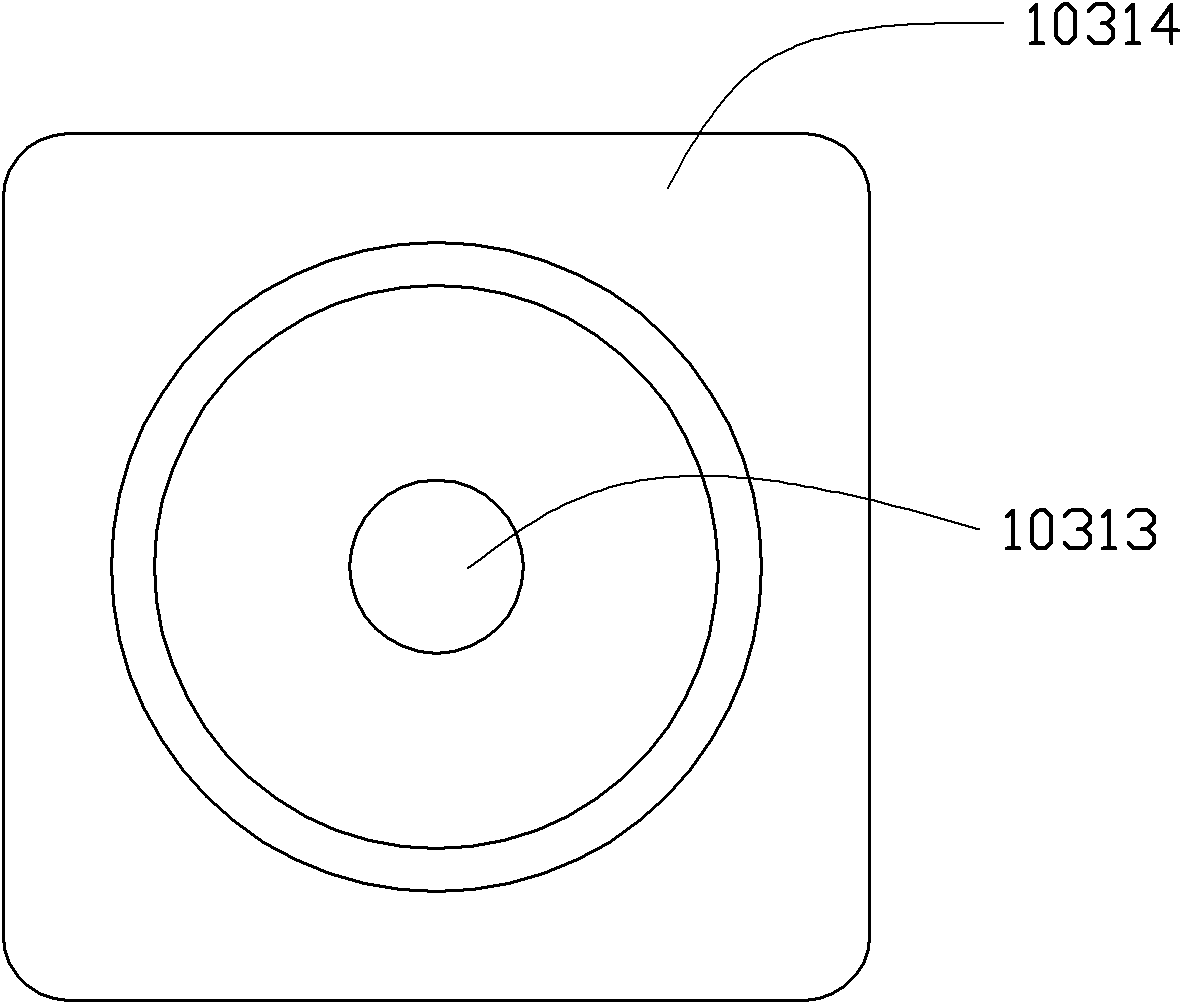

[0033] Please refer to Figure 1 to Figure 3 The pressing fixture 1031 of the preferred embodiment of the present invention has a first surface 10314 and a second surface 10315 opposite to each other, and the second surface 10315 is provided with four pressing parts 10311, and the pressing parts 10311 are separated from each other. And a groove 10312 is formed in the middle of each pressing part 10311 , so there are totally 4 grooves 10312 formed on the pressing fixture 1031 . A substantially cylindrical holding portion 10316 is formed on the first surface 10314, and the function of the holding portion 10316 is to facilitate a mechanical arm to grab the pressing jig 1031 and place the pressing jig 1031 Place on the heat sink 20 to fix the solid-state light source array 102 on the heat sink 20 .

[0034] For further explanation, please refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com