Connecting unit

A technology for connecting units and connectors, which is applied in the direction of connection, conductive connection, electrical connection of printed components, etc., and can solve problems such as not being able to ensure enough space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

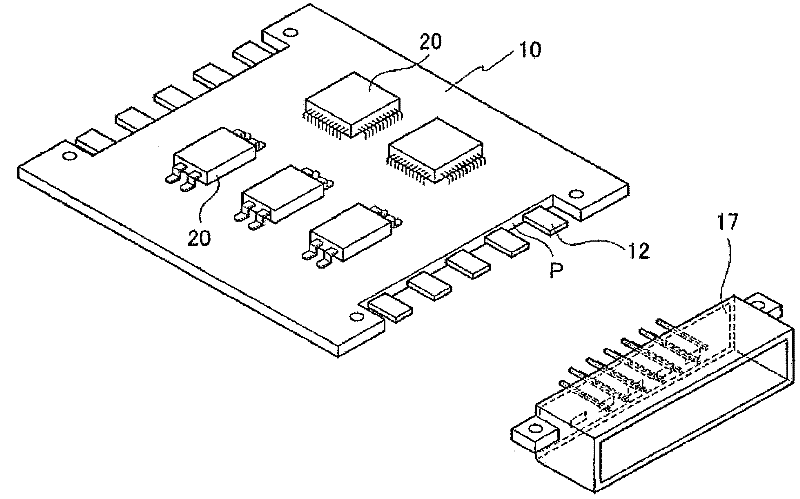

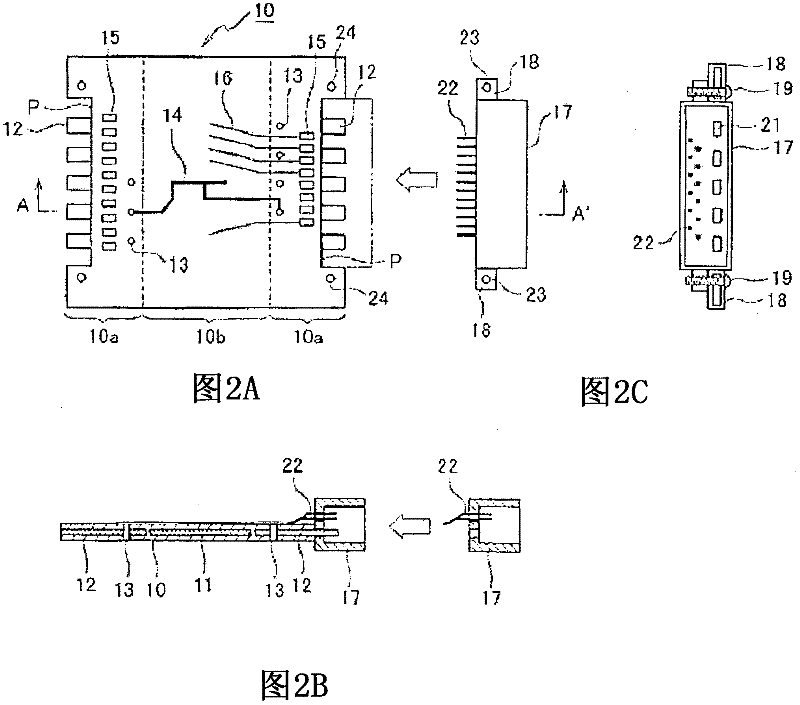

[0064] Preferred embodiments of the present invention will now be described with reference to the accompanying drawings. figure 1 is a perspective view showing a connector connection structure of a wiring board according to a preferred embodiment of the present invention, and 2A, 2B and 2C are a plan view, a front view (along line A-A) of a connector connection structure of the wiring board, respectively. 'Intercepted sectional view) and side view.

[0065] As shown in the drawing, the wiring board 10 of this embodiment has a generally rectangular shape as a whole, and each of the left end and the right end (in the drawing) of the wiring board 10 is notched to form a recess, and is notched The inner side (edge) of the portion (that is, the bottom of the concave portion) is formed as a linear side edge P. Such as figure 1 As shown, various electronic components 20 are mounted on the surface of the wiring board 10 .

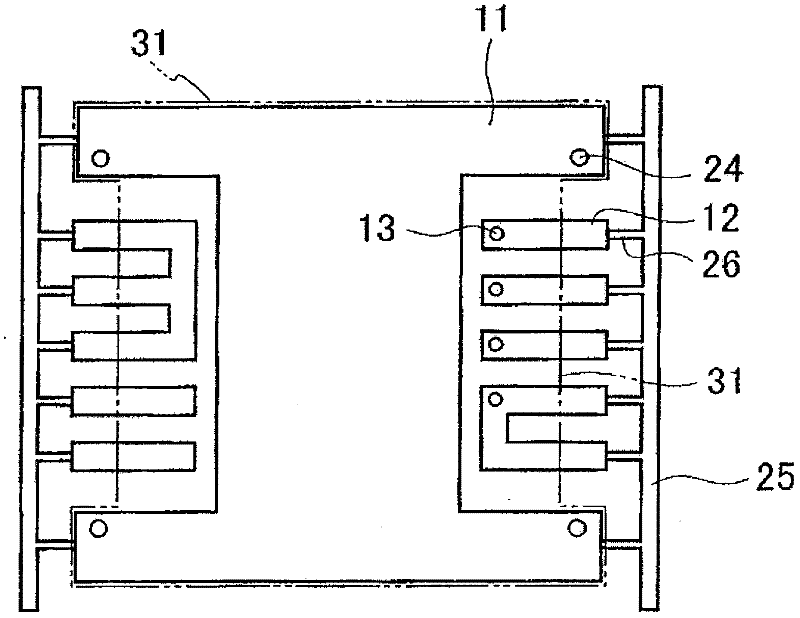

[0066] Such as Figure 2A As shown, the left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com