Developing shaft component of blueprinting machine

A technology of shaft components and image printing machines, which is applied in photography, optics, instruments, etc., can solve the problems of reducing image printing speed, low efficiency, environmental pollution, etc., and achieves the effect of convenient and rapid development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

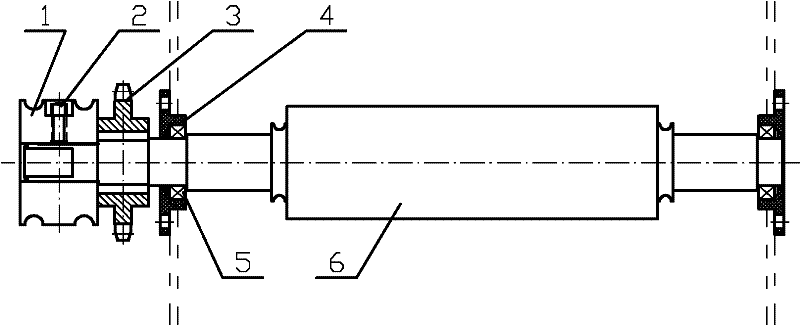

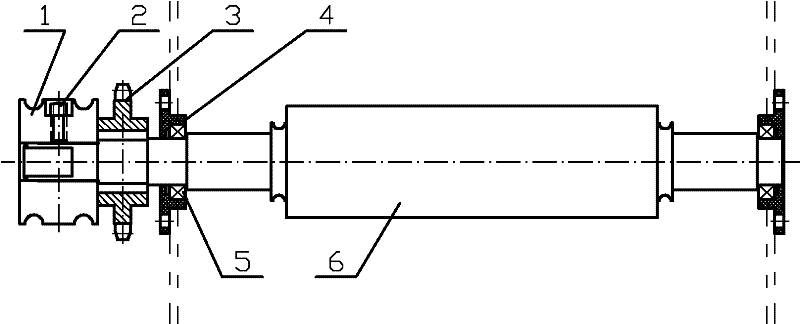

[0010] Such as figure 1 As shown, it includes O-ring belt pulley 1, O-ring belt pulley set screw 2, developing shaft transmission sprocket 3, bearing housing 4, bearing 5, and developing shaft 6.

[0011] A bearing 5 is embedded in the bearing seat 4; a developing shaft 6 is embedded in the bearing seat 4, the developing shaft drive sprocket 3 and the O-ring pulley 1 in sequence.

[0012] The O-ring pulley 1 is fixed on the developing shaft 6 through the O-ring pulley set screw 2 . The developing shaft 6 is a rubber shaft, the surface of which is coated with developer.

[0013] When working, through the action of the developing shaft, under the uniform pressure of the upper platen, the transmitted printing paper is brought into contact with the developing shaft, and the developer on the surface of the developing shaft is taken away, so that the print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com