Vibrationless fluidized bed drying machine

A vibrating fluidized bed and dryer technology, applied in dryers, drying solid materials, drying gas layout, etc., can solve the problems of difficulty in controlling the discharge speed, sticking to the bed surface, high noise, etc., and reduce ventilation. Pipes and elbows, avoid dead beds, improve the effect of the life of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

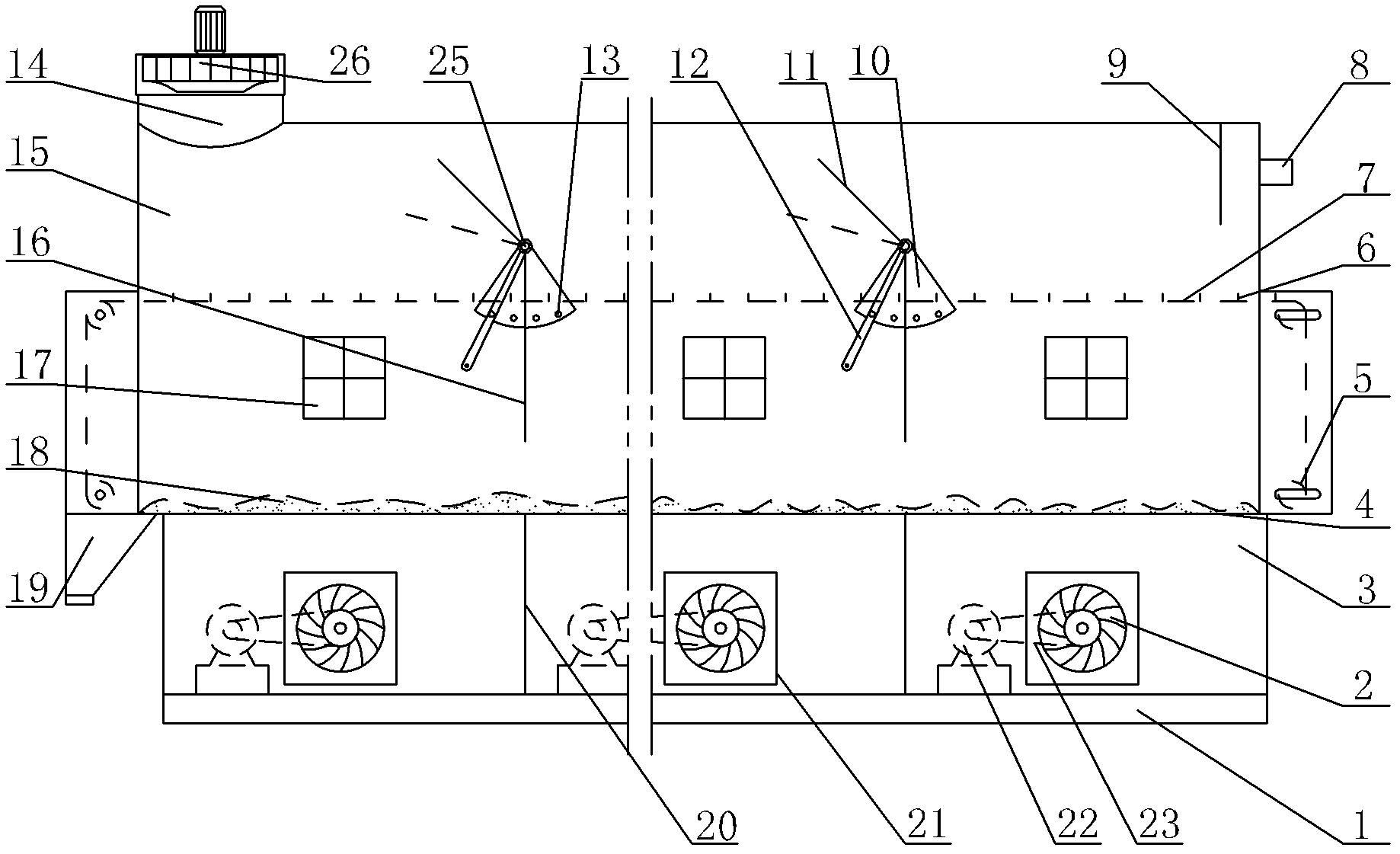

[0021] like figure 1 , 2 As shown, the non-vibration fluidized bed dryer of the present invention includes a base 1, a box body, a heat exchanger 24, an induced draft fan 26 and a dust collector 27, the box body is installed on the base 1, and the air outlet 14 of the box body Connect the induced draft fan 26, the induced draft fan 26 is connected to the dust collector 27, the air distribution plate 4 is arranged in the box and is divided into the upper box body 15 and the lower box body 3 by the air distribution plate 4, and the lower partition plate 20 is set in the lower box body 3, The lower partition 20 divides the lower casing 3 into a plurality of air chambers, and the corresponding lower partition 20 is provided with an upper partition 16 in the upper casing 15, and a blower device is arranged between two adjacent lower partitions 20 to blow air. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com