Hot melting range hood

A range hood and hot-melt technology are applied in the fields of removing oil fume, household heating, and household heating, etc., and can solve the problems of difficult cleaning of electric heating structures, small weight, and oil fume pollution of electric heating structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

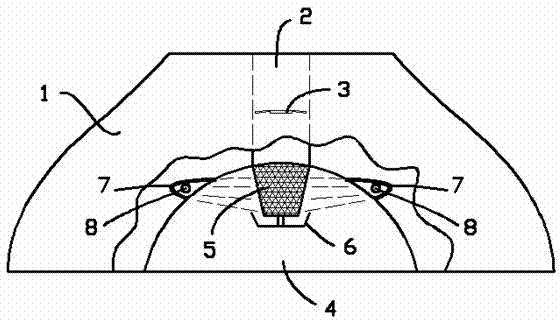

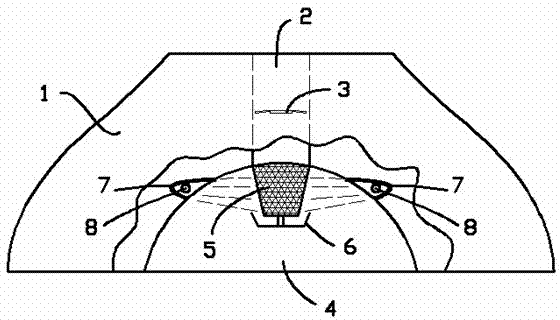

[0012] exist figure 1 Among them, the hot-melt range hood includes a cabinet 1, the cabinet 1 is provided with an air duct 2, the air duct 2 is provided with a fan 3, and below the fan 3 is an air suction cavity 4, between the air duct 2 and The interface of the suction cavity 4 is provided with a cup-shaped filter screen 5, the bottom of the filter screen 5 is an oil cup 6, and a heating cavity 7 is respectively provided on the left and right sides of the suction cavity 4. A far-infrared heater 8 is provided in the heating cavity 7, and a converging mirror is provided on the inner surface of the heating cavity 7, and the converging mirror can converge the far-infrared waves emitted by the far-infrared heater 8 to the filter screen 5 surface; the heating cavity 7 is sealed by a transparent sealing plate.

[0013] In the above hot-melt range hood, the converging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com