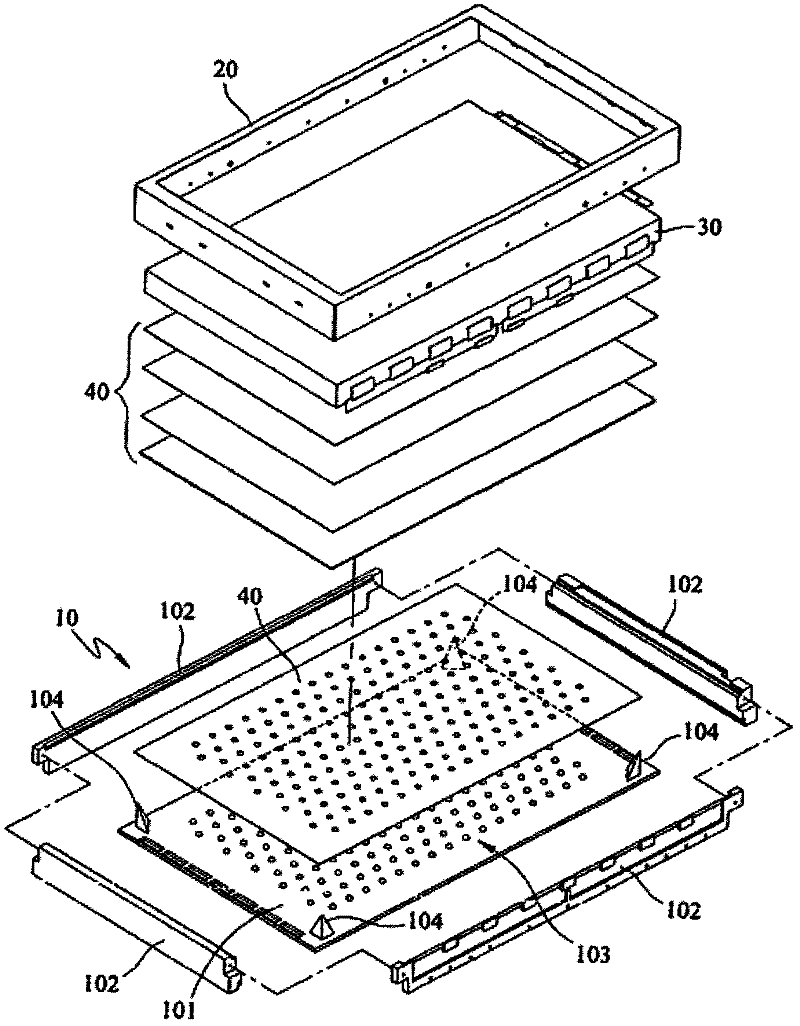

Liquid crystal display device and backlight module thereof

A liquid crystal display device and backlight module technology, applied in lighting devices, fixed lighting devices, components of lighting devices, etc., can solve problems such as uneven brightness distribution, achieve easy manufacturing and shape, and solve the effect of uneven brightness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

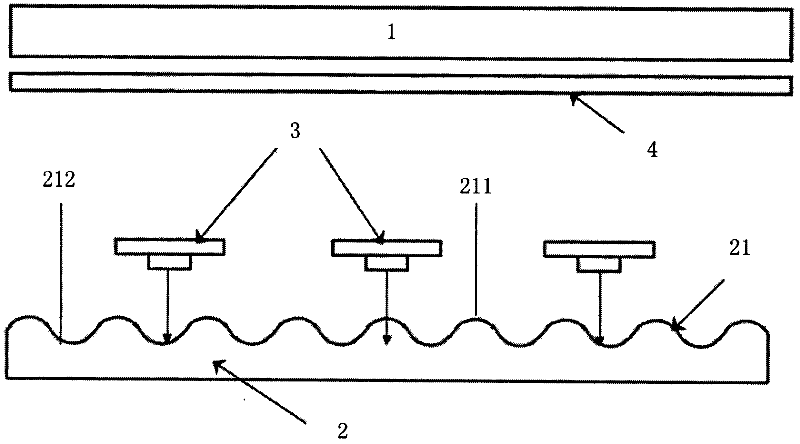

[0019] see figure 2 , the embodiment of the liquid crystal display device and its backlight module of the present invention roughly includes: a liquid crystal panel 1 , a back plate 2 , a light source 3 and a diffusion sheet 4 . in,

[0020] The upper surface of the backplane 2 is an uneven surface 21 . The uneven surface 21 is formed by a plurality of protrusions 211 and depressions 212 formed on the upper surface of the back plate 2 . Wherein, the arrangement of the plurality of protruding portions 211 and the recessed portions 212 may preferably be arranged side by side in a corrugated manner by a plurality of strip-shaped protruding portions 211 and strip-shaped recessed portions 212, or may be a plurality of The dot-shaped protrusions 211 and the dot-shaped depressions 212 are arranged in an array.

[0021] The light source 3 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com