Accelerator for enhanced biological removal of ammonia nitrogen in high ammonia nitrogen industrial wastewater and application thereof

A technology of industrial wastewater and accelerators, applied in the field of water treatment, can solve the problems of inconvenient operation and management, high cost, etc., and achieve the effect of good acid-base conditions, simple ingredients, and a wide range of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

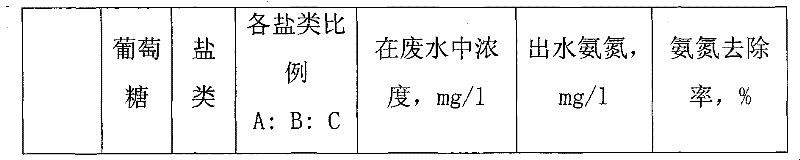

[0028] The accelerator of the present embodiment is prepared according to the required ratio, wherein formic acid is 100 parts by weight, glucose 20 parts by weight, salts 0.5 parts by weight, wherein iron citrate, CaCl 2 、Na 2 HPO 4 The molar ratio is 10:2:1, and the obtained effects are shown in Table 1.

[0029] The waste water tested in this example is leather waste water. After physical and chemical treatment, the waste water directly enters the biological treatment system. The water quality indicators entering the biological treatment system are as follows:

[0030] COD: 2200mg / l

[0031] NH 4 + -N: 190mg / l

[0032] pH value: 8.1

[0033] The sewage is treated by A / O (anaerobic aerobic process method), and the project water volume is 4000m 3 / d, the process conditions of nitrification tank operation are as follows:

[0034] Residence time: 33h

[0035] Temperature: 25-35°C

[0036] Control DO: 2-5mg / l

[0037] Return flow of nitrifying liquid: 2:1

[0038] Ac...

Embodiment 2

[0041] The accelerant of the present embodiment is prepared according to the required ratio, wherein 100 parts by weight of formic acid, 50 parts by weight of glucose, 1.5 parts by weight of salts, wherein ferric citrate, CaCl 2 、Na 2 HPO 4 The molar ratio is 10:1.5:0.5, and the obtained effects are shown in Table 1.

[0042] The test wastewater in this embodiment is leather wastewater. After physical and chemical treatment, the wastewater directly enters the biological treatment system. The water quality indicators entering the biological treatment system are as follows:

[0043] COD: 2200mg / l

[0044] NH 4 + -N: 190mg / l

[0045] pH value: 8.1

[0046] The sewage is treated by A / O (anaerobic aerobic process method), and the project water volume is 4000m 3 / d, the process conditions of nitrification tank operation are as follows:

[0047] Residence time: 33h

[0048] Temperature: 25-35°C

[0049] Control DO: 2-5mg / l

[0050] Return flow of nitrifying liquid: 2:1

...

Embodiment 3

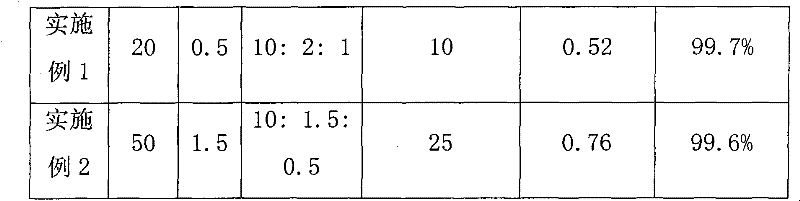

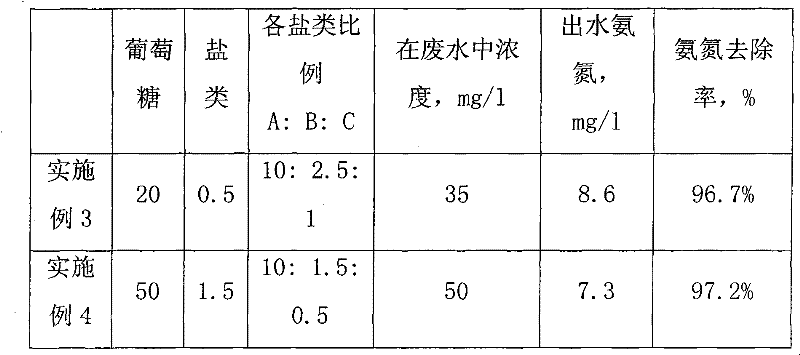

[0054] The accelerator of the present embodiment is prepared according to the required ratio, wherein formic acid is 100 parts by weight, glucose 20 parts by weight, salts 0.5 parts by weight, wherein iron citrate, CaCl 2 , NaH 2 PO 4 The molar ratio is 10:2.5:1, and the obtained effects are shown in Table 2

[0055] The test wastewater in this example is coking wastewater. After physical and chemical pretreatment, the wastewater directly enters the biological treatment system. The water quality indicators entering the biological treatment system are as follows

[0056] COD: 2500mg / l

[0057] NH 4 + -N: 260mg / l

[0058] pH value: 8.1

[0059] The sewage is treated by A / O (anaerobic aerobic process method), and the project water volume is 1800m 3 / d, the process conditions of nitrification tank operation are as follows:

[0060] Residence time: 28h

[0061] Temperature: 25-35°C

[0062] Control DO: 2-5mg / l

[0063] Return flow of nitrifying liquid: 2:1

[0064] Accele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com