Preparation method of lithium titanate with special morphology

A technology of lithium titanate and morphology, applied in the field of electrochemical materials, can solve the problems of low theoretical capacitance, limited electrochemical performance and application of lithium titanate, low electronic conductivity, etc. The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

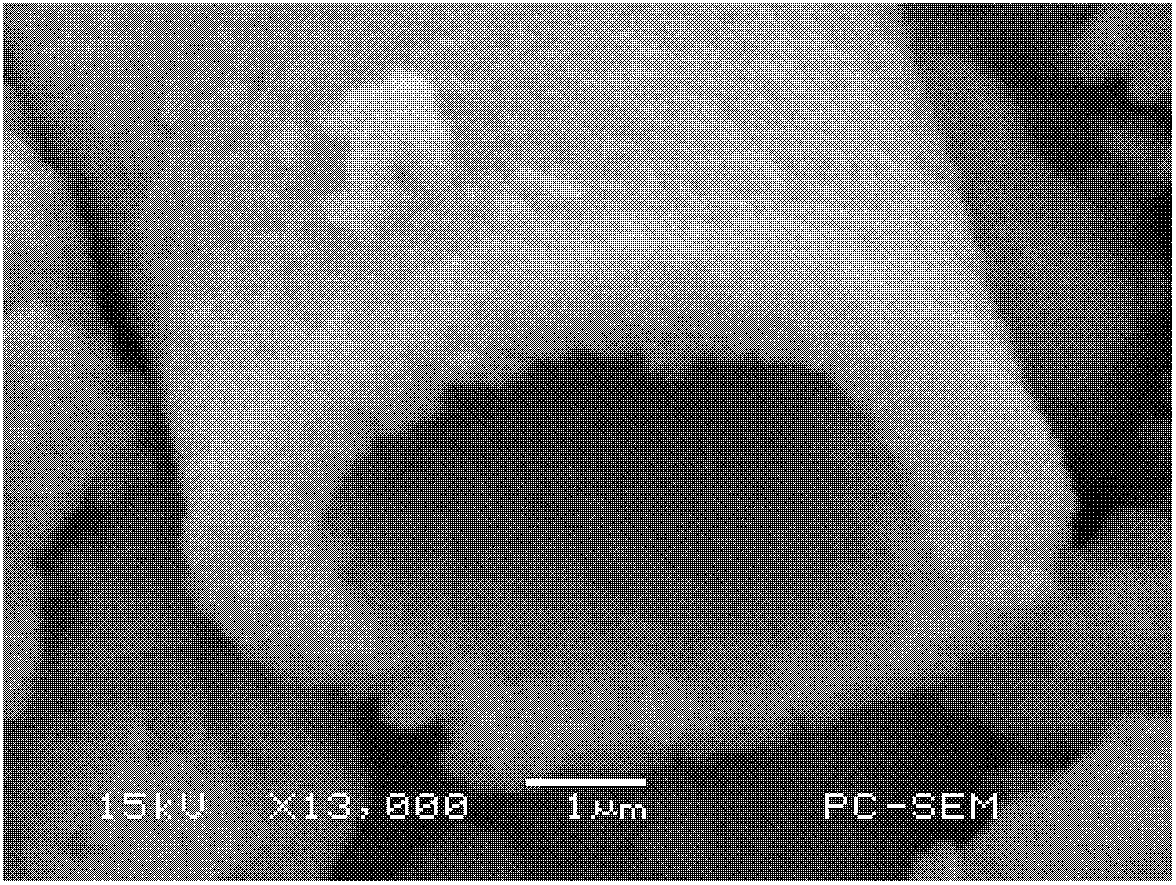

[0031] A kind of method that prepares tubular lithium titanate with bamboo fiber as template, comprises the following steps:

[0032] (1) Take 0.75g of pulverized bamboo fibers, add 20ml of lithium acetate ethanol solution with a concentration of 0.69mol / L, and disperse ultrasonically for 1 hour (ultrasonic frequency is 35KHz) to obtain suspension A.

[0033] (2) According to the molar ratio Li / Ti=0.8, an appropriate amount of tetrabutyl titanate was dropped into the suspension A above to obtain the suspension B. After continuous stirring for 8 minutes, the suspension B was placed on a temperature-controlled magnetic stirrer, stirred and evaporated to dryness at 60° C. to obtain a precursor C of tubular lithium titanate.

[0034] (3) Grind C and place it in a muffle furnace for segmental calcination under air conditions (calcination conditions: calcination at 450°C for 5 hours and then calcination at 750°C for 10 hours), and then cool to 30°C to obtain tubular lithium titanate...

Embodiment 2

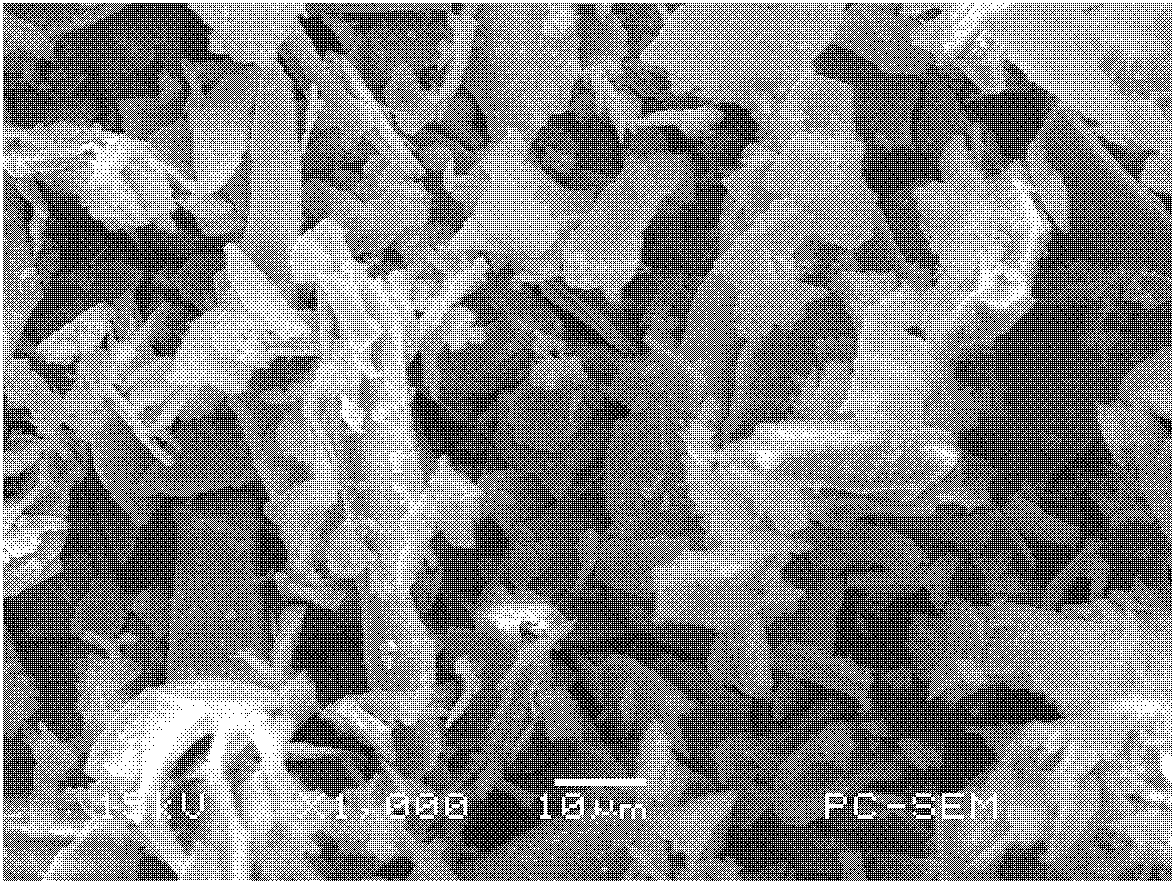

[0041] A method for preparing sheet lithium titanate with bagasse fiber as a template, comprising the following steps:

[0042] (1) Take 1 g of crushed bagasse, add 20 ml of 0.5 mol / L lithium acetate ethanol solution, and ultrasonically disperse for 1 hour (ultrasonic frequency is 35KHz) to obtain suspension A.

[0043] (2) According to the molar ratio Li / Ti=0.82, an appropriate amount of tetrabutyl titanate was dropped into the suspension A above to obtain the suspension B. After continuous stirring for 10 minutes, the suspension B was placed on a temperature-controlled magnetic stirrer, stirred and evaporated to dryness at 80°C to obtain a precursor C of tubular lithium titanate.

[0044] (3) Grind C and place it in a muffle furnace for calcination in sections under air conditions (calcination conditions: calcination at 450°C for 5 hours and then calcination at 750°C for 10 hours), and then cool to 40°C to obtain flaky lithium titanate products: Such as figure 2 As shown,...

Embodiment 3

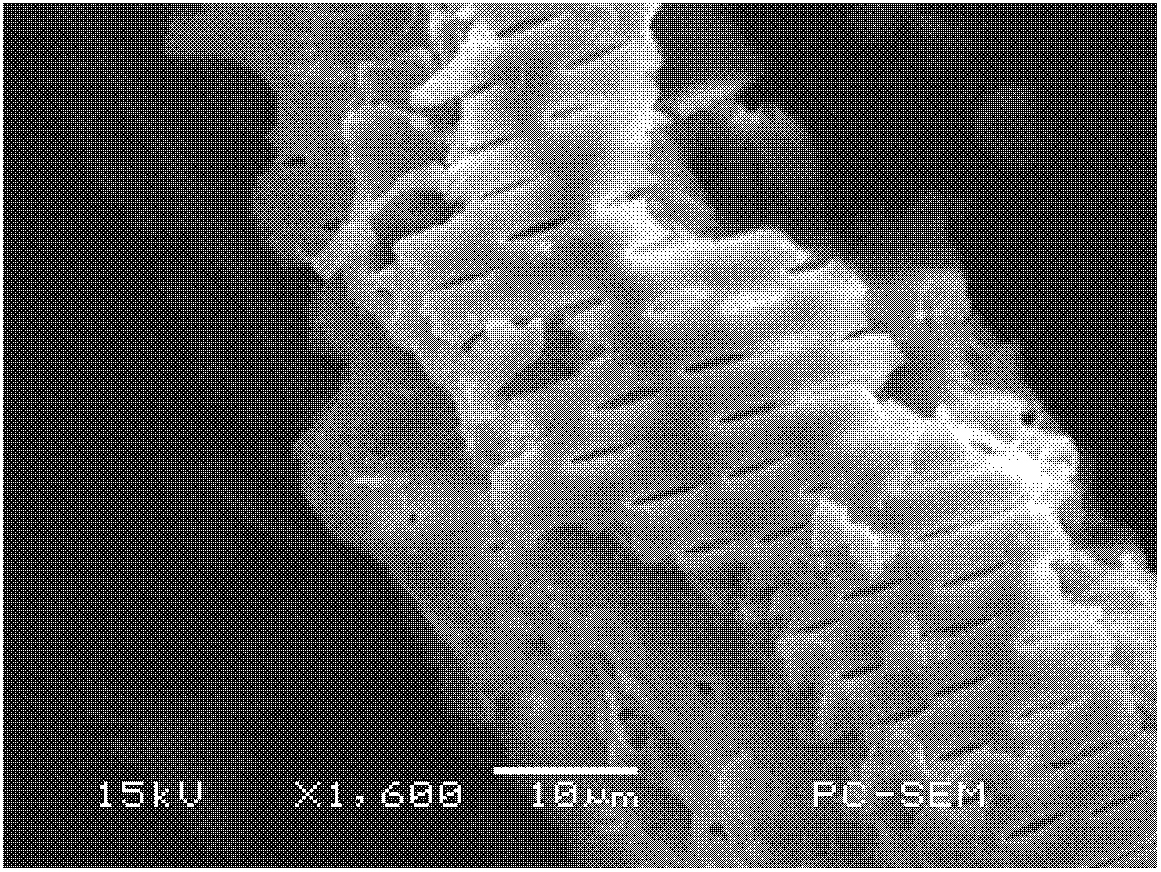

[0049] A method for preparing porous block lithium titanate with bamboo charcoal as a template, comprising the following steps:

[0050] (1) Take 0.5 g of pulverized bamboo charcoal, add 20 ml of lithium acetate ethanol solution with a concentration of 1.0 mol / L, and ultrasonically disperse for 1 hour (ultrasonic frequency is 35KHz) to obtain suspension A.

[0051] (2) According to the molar ratio Li / Ti=0.84, an appropriate amount of tetrabutyl titanate was dropped into the suspension A above to obtain the suspension B. After continuous stirring for 5 minutes, the suspension B was placed on a temperature-controlled magnetic stirrer, stirred and evaporated to dryness at 40° C. to obtain a precursor C of tubular lithium titanate.

[0052] (3) After grinding C, place it in a muffle furnace for segmental calcination under air conditions (calcination conditions: calcination at 450°C for 5 hours, then calcination at 750°C for 10 hours), and then cool to 25°C to obtain porous block l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com