Acid supplementing apparatus and acid supplementing system used for storage batteries, and application method thereof

A technology for batteries and acid supplementation, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of acid spill, ignition, terminal corrosion, etc., to reduce workload, improve acid supplementation efficiency, and ensure production safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

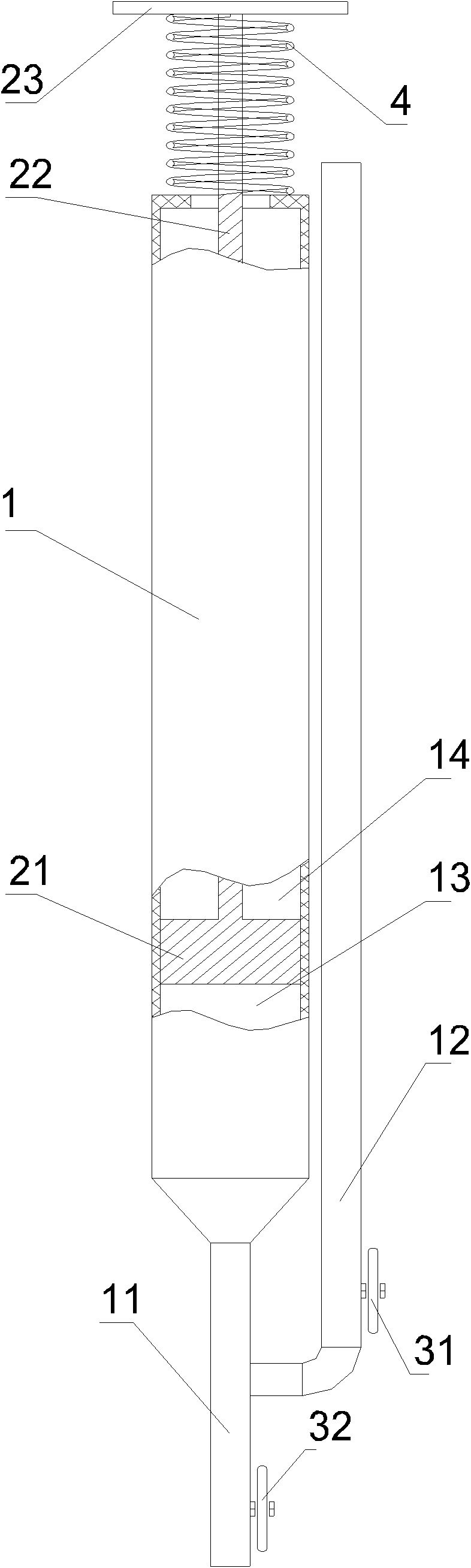

[0025] Please refer to figure 1 , the acid replenishing device for storage battery of the present invention includes a main body 1, a driving part and at least two control parts. The inside of the main body 1 is provided with a cavity, and the driving member includes a sliding part 21 and a force applying part 22 for driving the sliding part 21 to perform work. The sliding part 21 is sealed and matched with the inner wall of the cavity to form a sliding pair, which divides the cavity into an acid chamber 13 and a movable chamber 14, and the wall of the acid chamber 13 is provided with an acid outlet for communicating with the acid supply port of the battery. The channel 11 and the acid inlet channel 12 for communicating with the acid storage device, at least one control member 31 , 32 for controlling the opening and closing of the acid inlet channel 12 and the acid outlet channel 11 are arranged respectively. The chamber wall of the movable chamber 14 is provided with an inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com