Lever type laser detection device for material tension

A laser detection and lever-type technology, applied in the direction of measuring devices, optical devices, and analyzing materials, can solve the problems of unfavorable on-site teaching, small working space, and large noise, and achieve intuitive and open test process, easy installation and operation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

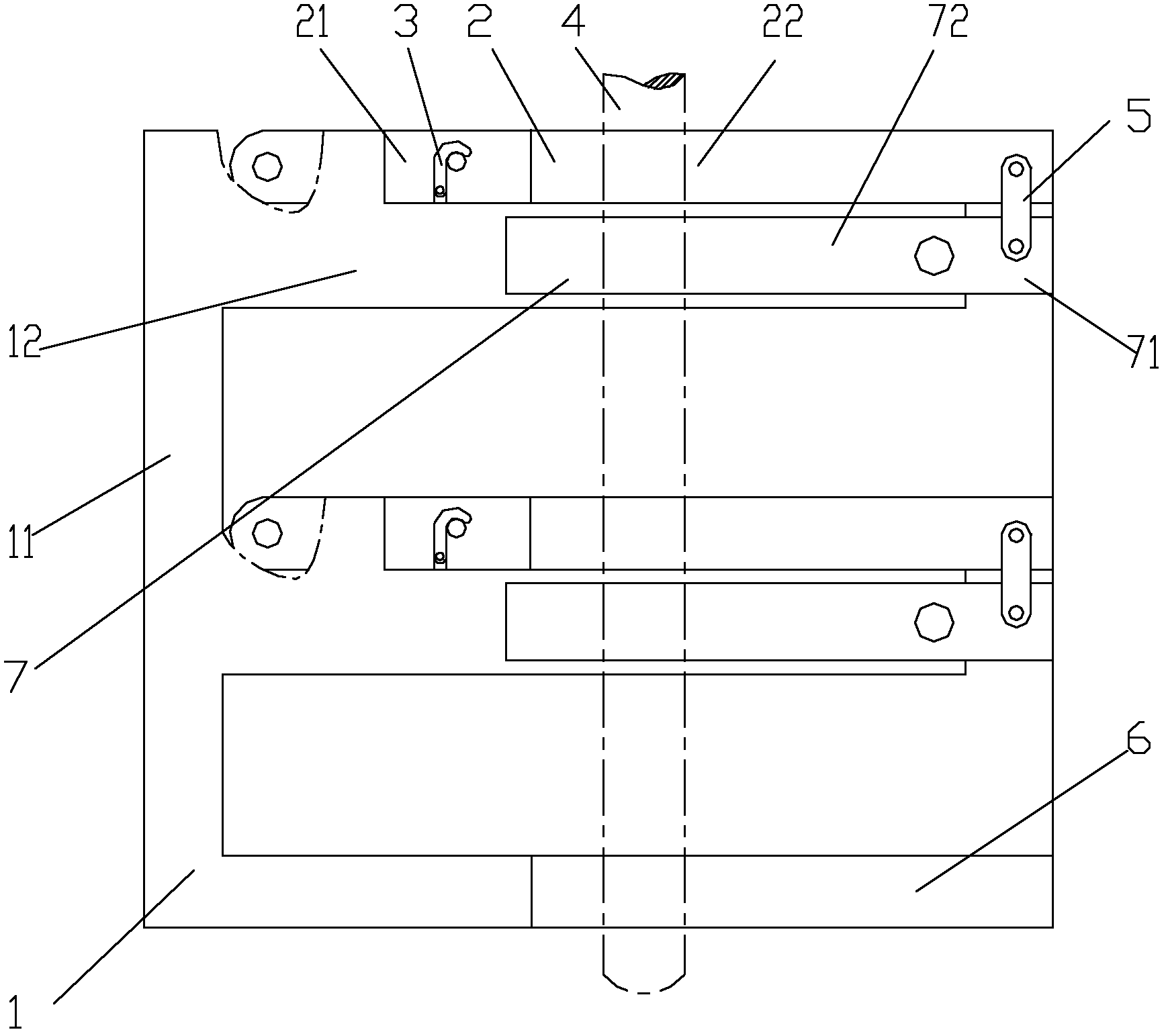

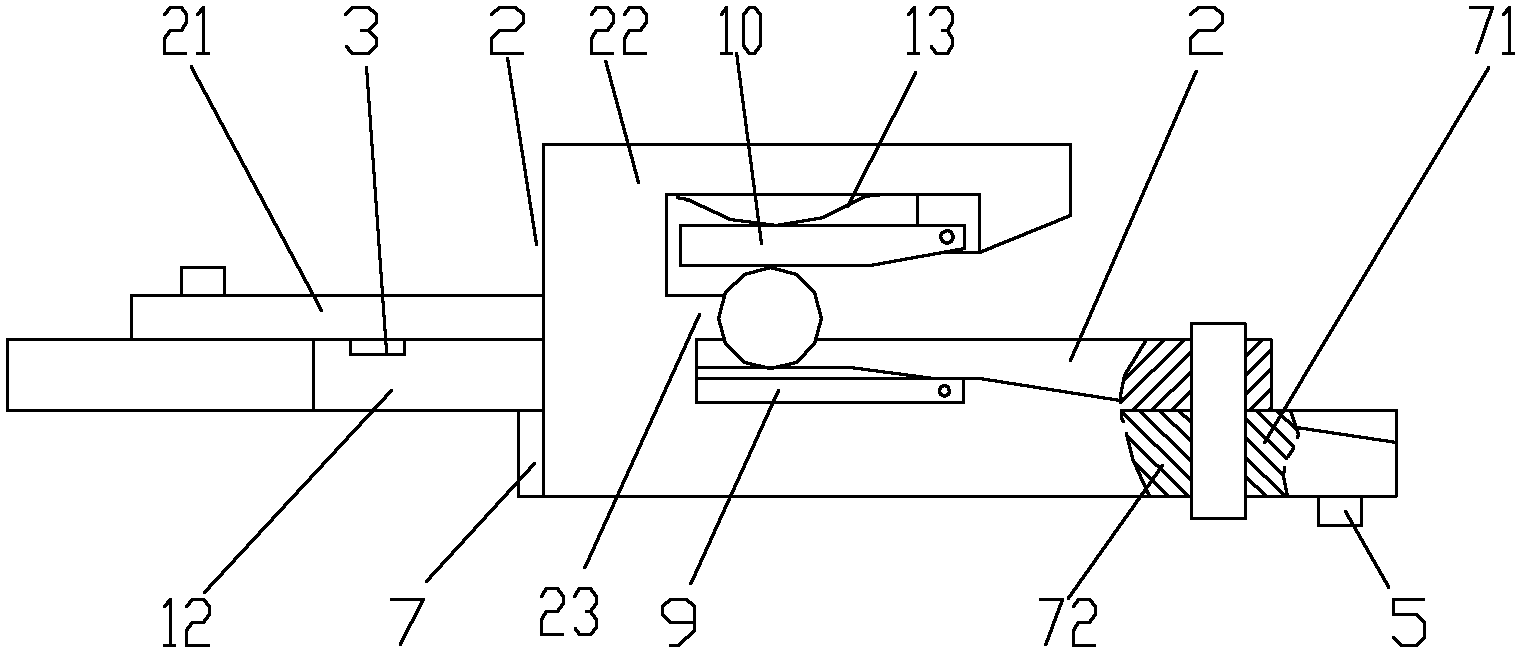

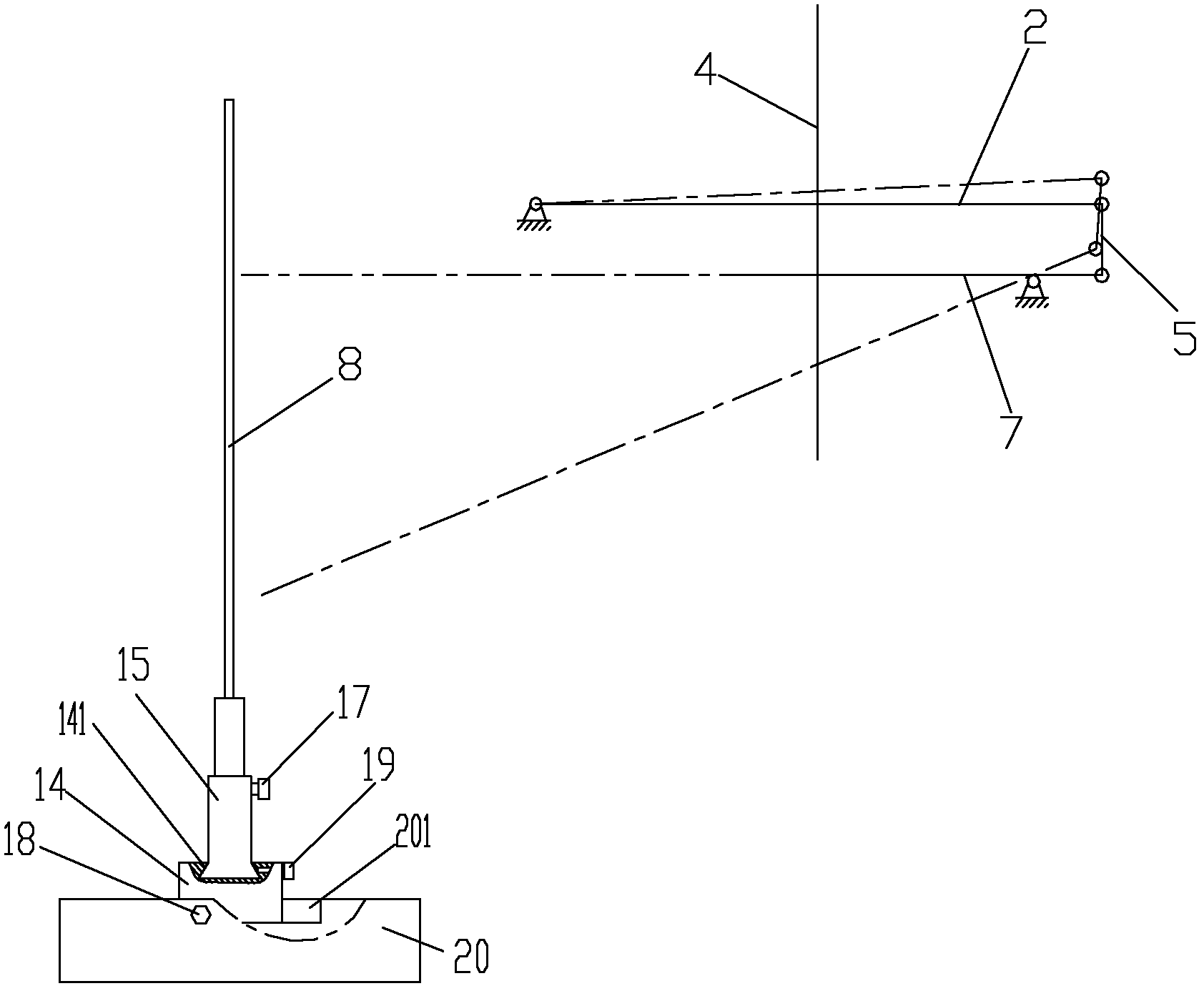

[0024] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 View along direction A, image 3 It is a schematic diagram of the present invention, as shown in the figure: the material stretching lever type laser detection device of this embodiment includes a support frame 1 and a laser detection assembly;

[0025] The laser detection assembly is at least two groups arranged side by side along the stretching direction of the test piece. In this embodiment, there are two groups; including the laser 7, the gauge fork 2 and the connecting rod 5, the casing of the laser 7 is hinged to the support frame 1 to form a lever structure , one end of the gauge fork 2 is hinged to the support frame 1 in such a way that the gauge fork 2 can rotate along the stretching direction of the test piece 4, that is, it can be hinged by a spherical hinge, or it can be perpendicular to the stretching direction of the test piece. The three hinge shafts ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com