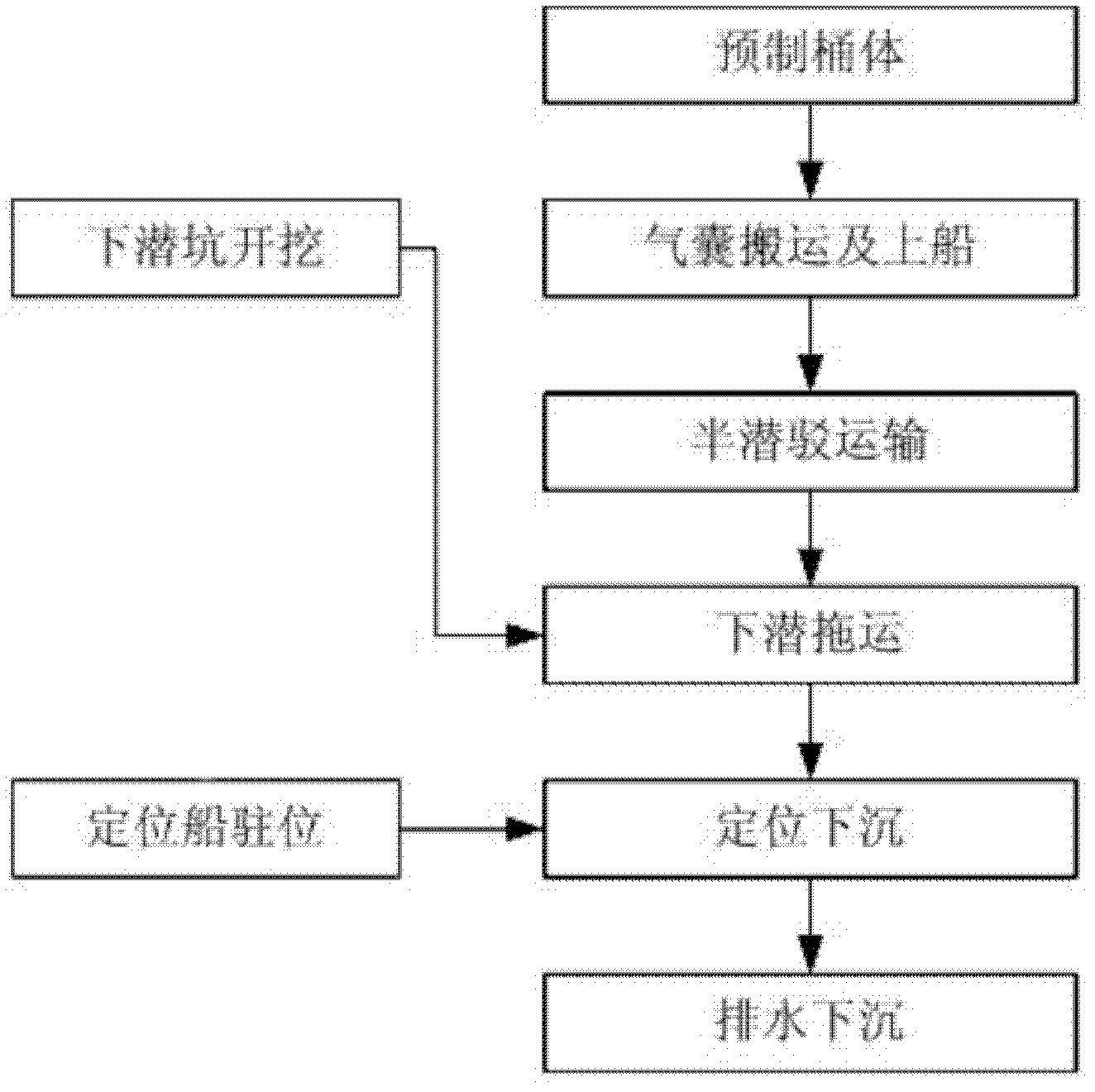

Transportation and installation process of base barrel body of barrel type breakwater

A foundation barrel and installation process technology, applied in breakwaters, foundation structure engineering, embankments, etc., can solve problems such as inability to resist wind and waves, inability to construct, and difficulty in mastering balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] In this embodiment, the design water level is as follows:

[0037] Design high water level 5.41m (accumulation frequency of high tide 10%)

[0038] Design low water level 0.47m (low tide cumulative frequency 90%)

[0039] The water depth of the proposed bucket breakwater is about -5m.

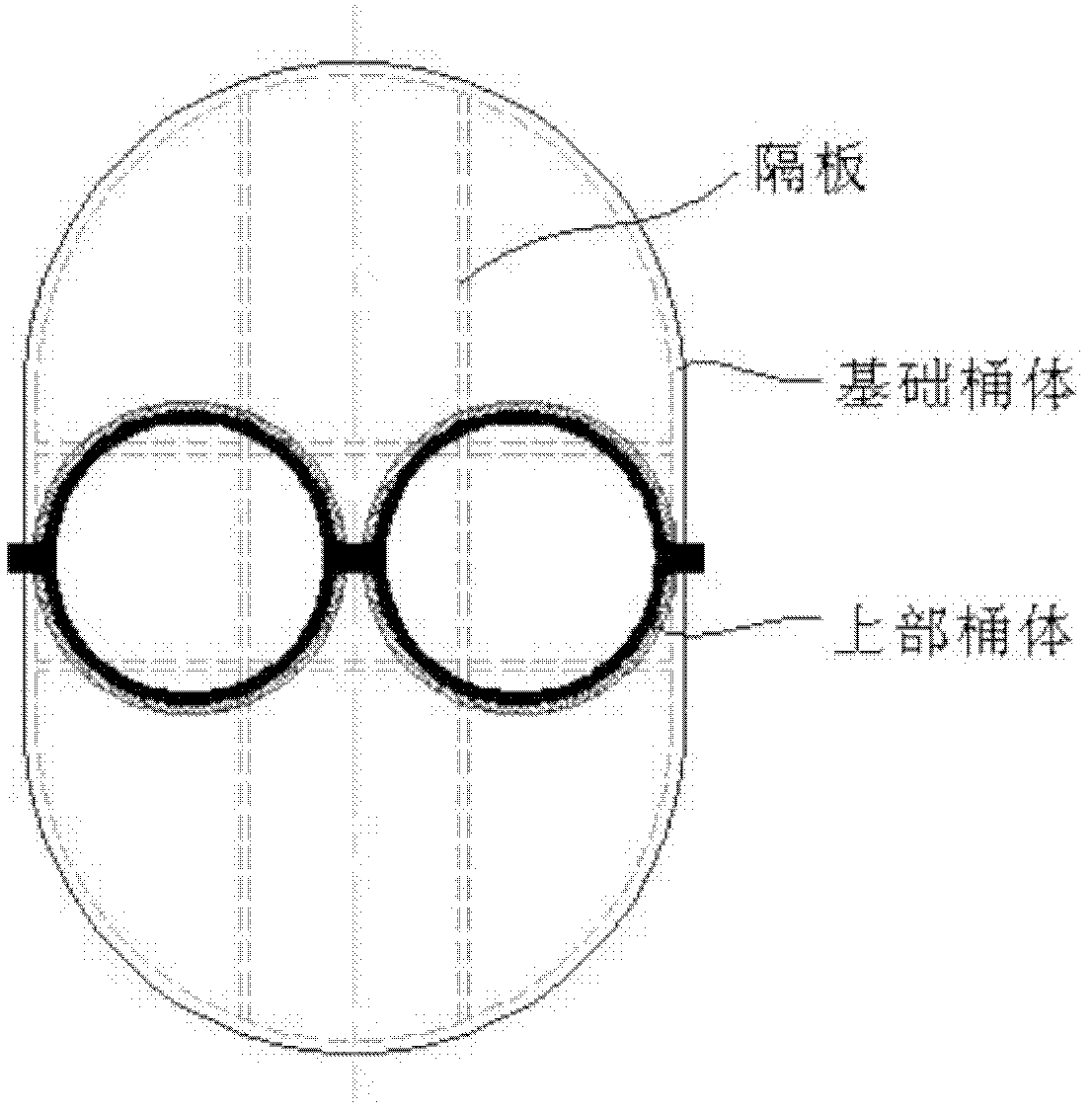

[0040] Such as figure 1 , figure 2 As shown, in this embodiment, the axial length of each group of barrel members is 20m, the installation distance between two adjacent groups of foundation structures is 1.0m, and the distance between the upper barrels is 10cm-20cm.

[0041] The dimensions of the foundation barrel are: the long axis of the lower elliptical foundation barrel is 30m, the short axis is 20m, the height is 9.0m, the thickness of the outer wall is 40cm, the wall thickness of the partition is 30cm, and the thickness of the top plate is 40cm; the wall thickness of the upper barrel body is 35cm, The barrel is 15.28m high.

[0042] The typical overall dimensions of each grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com