Electronic spot welding machine with double spot welding heads

An electronic spot and double-spot welding technology, which is applied in the direction of welding power supply, manufacturing tools, welding equipment, etc., can solve the problems that the electronic spot welding machine can not realize double-point spot welding at the same time, so as to reduce labor production costs, improve production efficiency, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

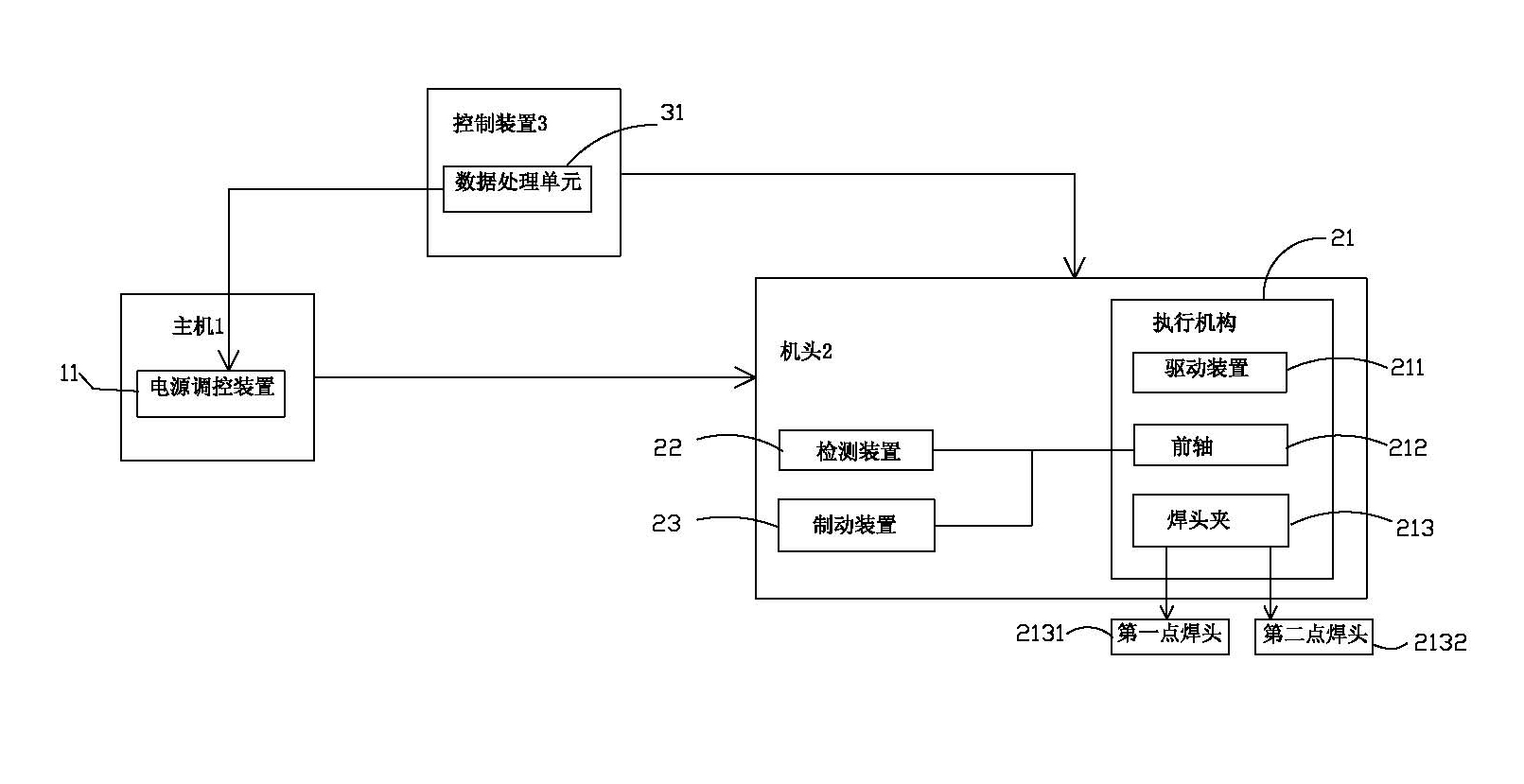

[0015] Please refer to figure 1 Shown is a schematic block diagram of the present invention. The invention provides an electronic spot welding machine with a double-point welding head, which uses the double-point welding head to simultaneously complete automatic paint removal and simultaneous spot welding of the double-point welding head, and realizes closed-loop automatic control on the energy output circuit of the double-point welding head And the function of real-time detection, so as to achieve the precise and stable control of the energy output of the double-spot welding head, ensure the high precision requirements of electronic components, improve the production efficiency of components and reduce the production labor cost.

[0016] Wherein, the described electronic spot welding machine with double spot welding heads comprises a main frame 1, a head 2 and a control device 3, the main frame 1 is provided with a power regulating device 11 and is connected to the head 2 cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com