High-precision and low-speed stirring system with low heat quantity

A low-speed stirring, high-precision technology, used in mixer accessories, dissolving, mixers, etc., which can solve the problems of large temperature difference on the surface of the stirring device and affecting the measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

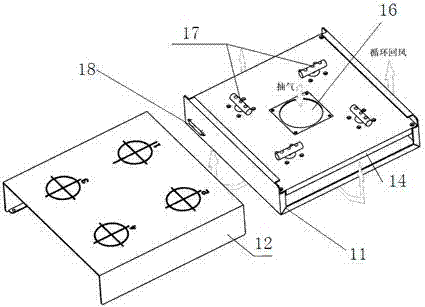

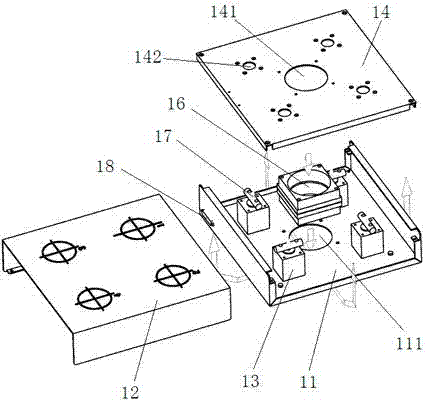

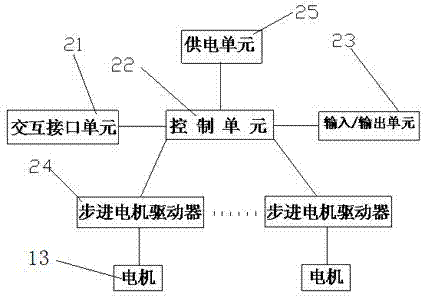

[0021] The present invention will be specifically described below in conjunction with the accompanying drawings.

[0022] During the use of small-scale reaction devices (such as animal cell reactors, etc.), when the reaction process is carried out by placing the reaction device in a constant temperature environment (such as in an incubator), the temperature of the reaction process is controlled by the ambient temperature , while the ambient temperature is controlled by, for example, an incubator. The industry standard for animal cell culture devices "JB / T 20137-2011 Mechanically Stirred Animal Cell Culture Tank" has the following performance requirements for animal cell reactors:

[0023] 5.4.5 The temperature of the culture medium should be able to be set at room temperature below 37°C, and the allowable error range is ±0.2°C.

[0024] 5.4.6 The pH value of the culture solution should be able to be set within the range of 6 to 9, and the allowable error range is ±0.02.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com