Antifungal and antibacterial agent for waterproof leather product and preparation method of antifungal and antibacterial agent

A technology of antifungal and antibacterial agents and leather products, applied in botany equipment and methods, chemicals for biological control, biocides, etc., can solve the health hazards of users, limited effective time, and dissolution and loss of antifungal agents and other problems, to achieve excellent antibacterial effect, water-resistant antibacterial effect, and excellent water-resistant immersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

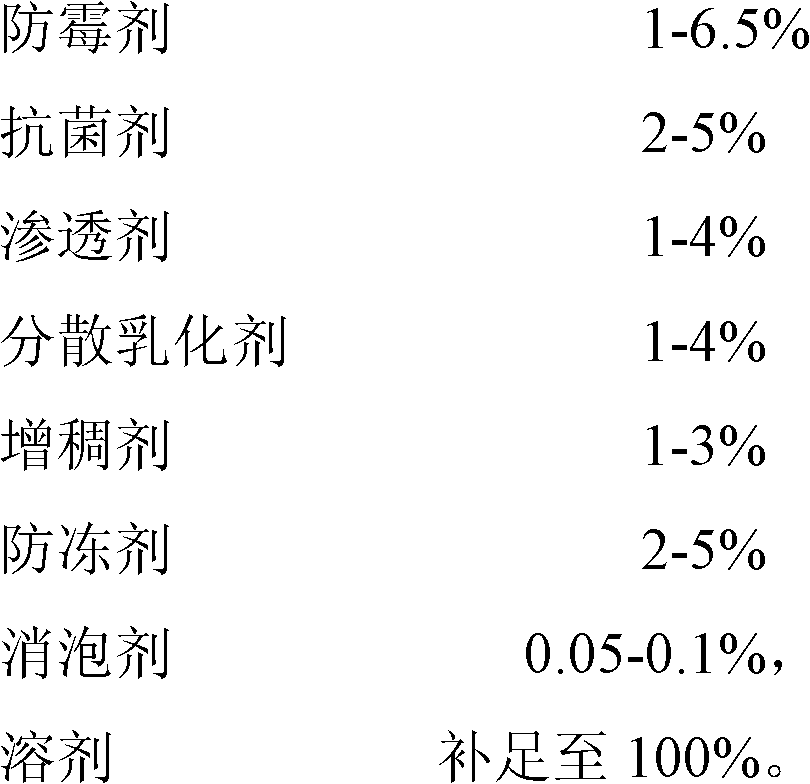

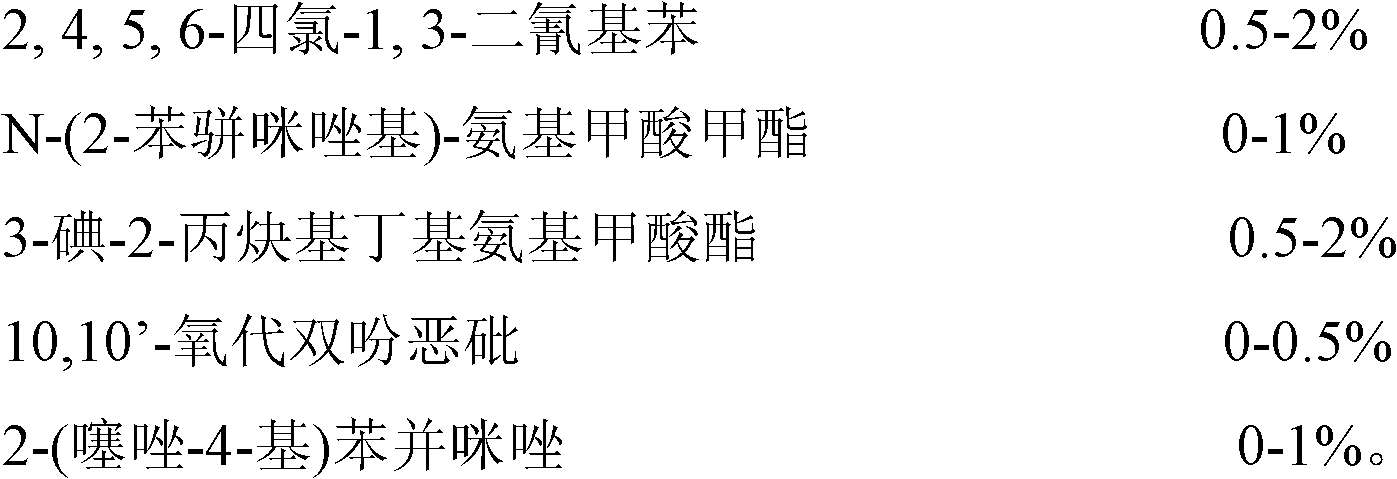

Method used

Image

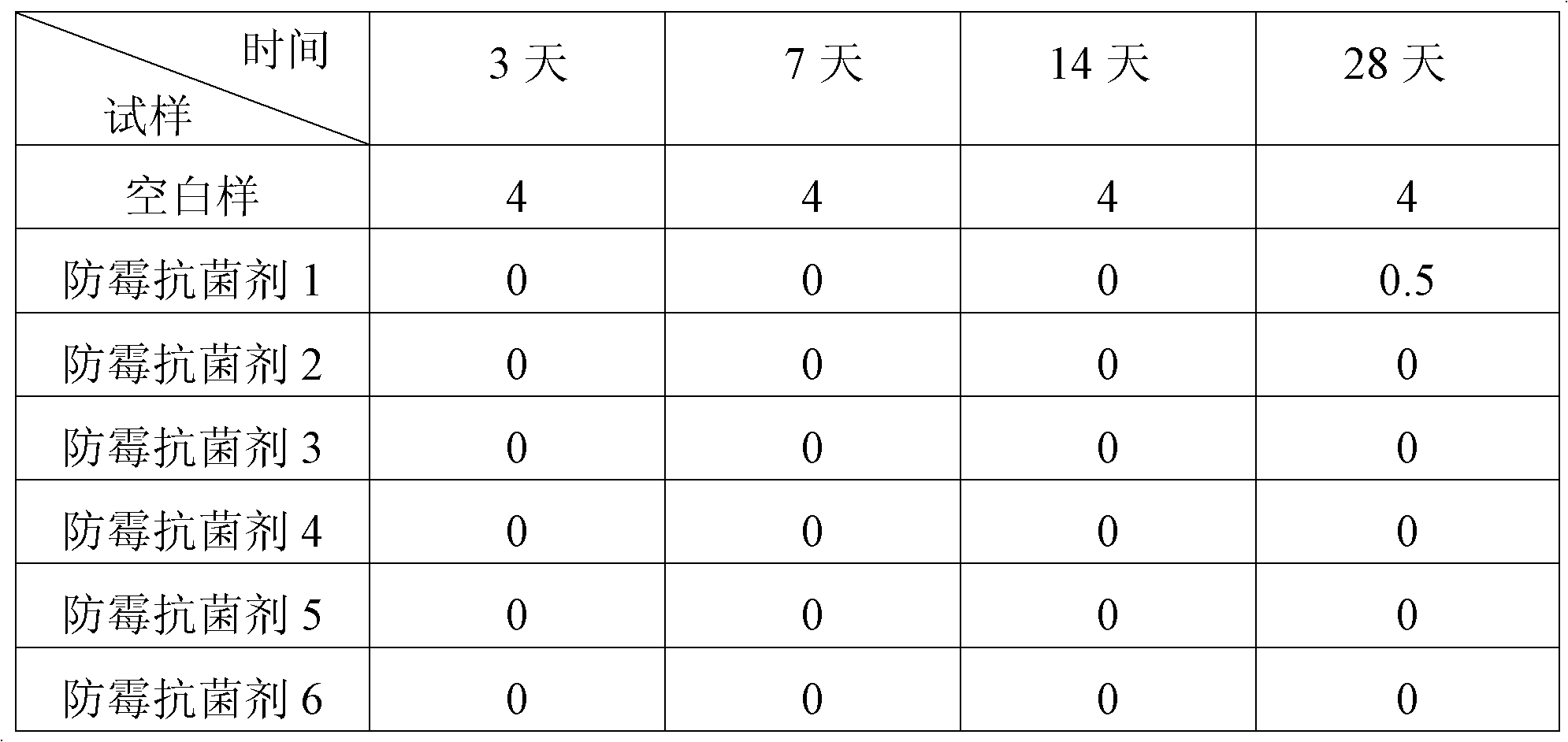

Examples

Embodiment 1

[0037] 1.0% by weight of 2,4,5,6-tetrachloro-1,3-dicyanobenzene, 1.0% by weight of 3-iodo-2-propynylbutylcarbamate, 5% by weight The graft type quaternary ammonium salt cationic antibacterial agent (WS-8810) of fraction, the fatty alcohol polyoxyethylene ether (JFC) of 2% parts by weight, the styrylphenol polyoxyethylene ether (Nong milk 600 of 2% parts by weight) ) mixed with water of 84.95% by weight. The mixture is then fed into a disperser for dispersion. Wherein the rotating speed of the disperser is 1000 rpm, and the dispersion time is 45 minutes. If foaming occurs at this time, add 0.05% by weight of silicone defoamer. Then, after the mixture is uniformly dispersed, it is transferred to a sand mill for sand grinding. Wherein the rotating speed of sand mill is 1600 rev / mins, and sand mills 1 hour. After the sanding is completed, add 2% by weight of polyurethane thickener and 2% by weight of ethylene glycol, and evenly disperse to obtain the finished product of the wa...

Embodiment 2

[0039] 0.5% by weight of 10,10'-oxobisphenoxarsine, 0.5% by weight of 3-iodo-2-propynyl butyl carbamate, 4% by weight of grafted quaternary ammonium salt Cationic antibacterial agent (WS-8810), 3% weight fraction of fatty alcohol polyoxyethylene ether (JFC), 1% weight fraction of styrylphenol polyoxyethylene ether (Nongru 600) and 84.95% weight fraction of water mix. The mixture is then fed into a disperser for dispersion. Wherein the rotating speed of the disperser is 2000 rpm, and the dispersion time is 30 minutes. If foaming occurs at this time, add 0.05% by weight of silicone defoamer. Then, after the mixture is uniformly dispersed, it is transferred to a sand mill for sand grinding. Wherein the rotating speed of sand mill is 1200 rev / mins, sand mill 2 hours. After the sanding is completed, add 1% by weight of polyurethane thickener and 5% by weight of ethylene glycol, and evenly disperse to obtain the finished antifungal and antibacterial agent for water-resistant lea...

Embodiment 3

[0041] 0.5% by weight of 10,10'-oxobisphenoxarsen, 2.0% by weight of 3-iodo-2-propynyl butyl carbamate, 2% by weight of grafted quaternary ammonium salt Cationic antibacterial agent (WS-8810), 4% weight fraction of fatty alcohol polyoxyethylene ether (JFC), 4% weight fraction of styrylphenol polyoxyethylene ether (Nongru 600) and 80.95% weight fraction of di Methylacetamide mixed. The mixture is then fed into a disperser for dispersion. Wherein the rotating speed of the disperser is 3000 rpm, and the dispersion time is 10 minutes. If foaming occurs at this time, add 0.05% by weight of silicone defoamer. Then, after the mixture is uniformly dispersed, it is transferred to a sand mill for sand grinding. Wherein the rotating speed of sand mill is 1400 rev / mins, and sand mills 1 hour. After the sanding is completed, add 2% by weight polyurethane thickener and 4.5% by weight ethylene glycol, and evenly disperse to obtain the finished antifungal and antibacterial agent for water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com