Squirrel-cage rotor

A squirrel-cage rotor and rotor lamination technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of slow starting speed and heavy weight of all-copper squirrel-cage rotors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

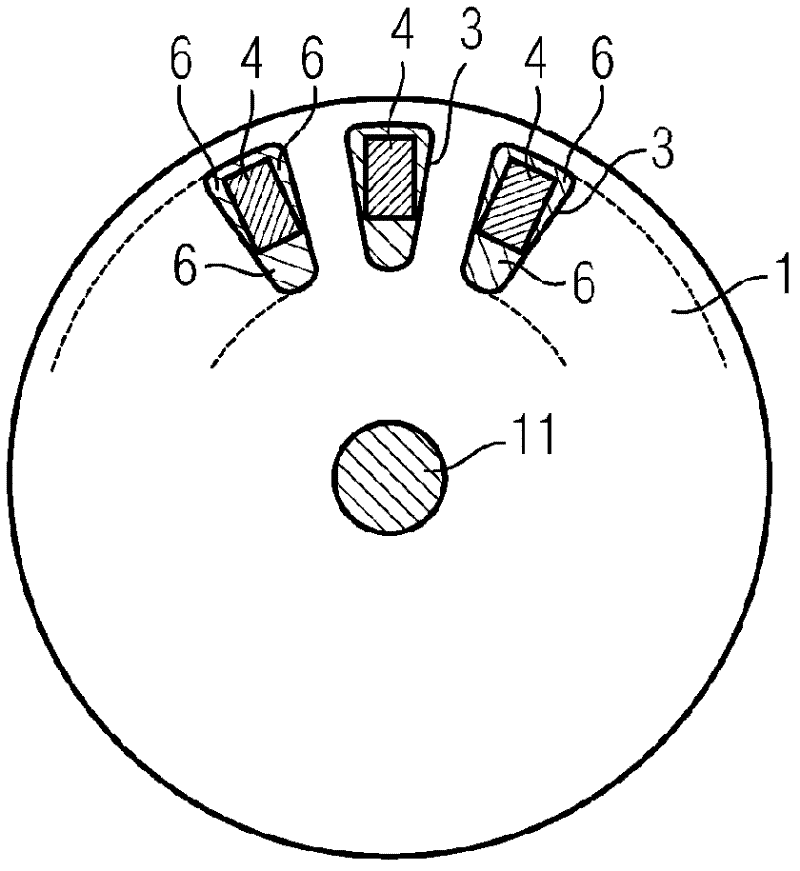

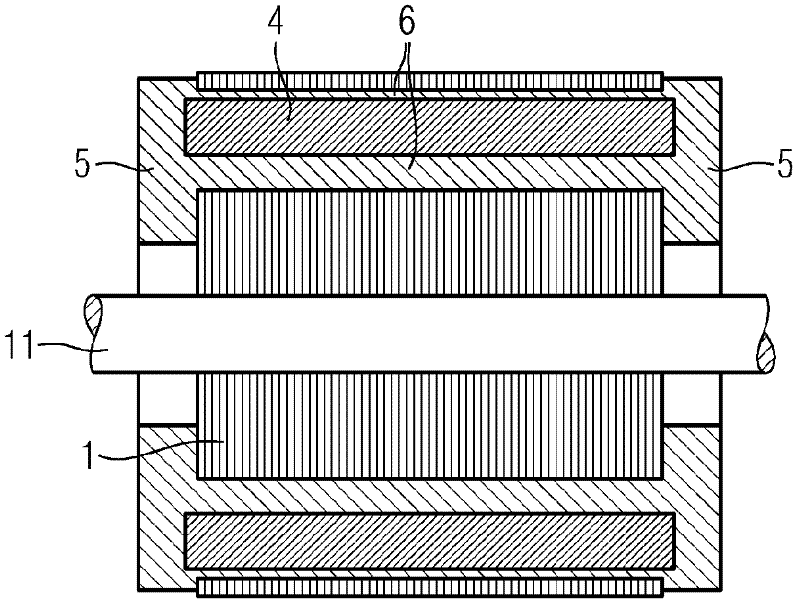

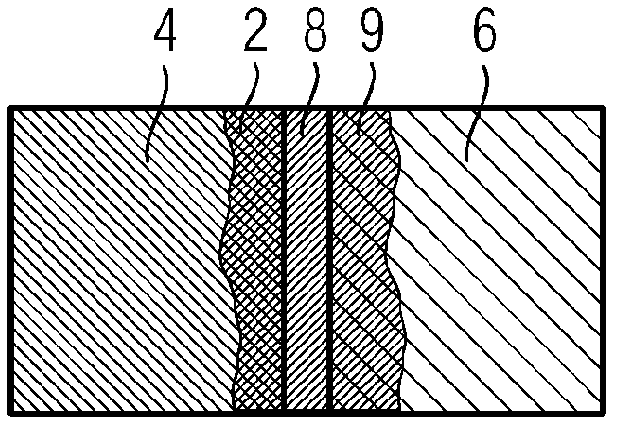

[0040] figure 1 An embodiment with a hybrid-structure squirrel-cage rotor for an asynchronous machine. The figure shows the laminated rotor core 1 of the asynchronous motor, which is shrink-fitted on the shaft body 11 . To manufacture such a squirrel-cage rotor, it is first necessary to insert conductors 4 , preferably made of copper, into the slots 3 of the laminated rotor core 1 . As shown, the cross-section of the conductor 4 is smaller than the cross-section of the slot 3 . Therefore, after the conductor 4 (in the form of a copper strip) is inserted, there will still be a residual section in the slot 3 .

[0041] The next step in manufacturing a squirrel cage rotor is the die casting process. This process produces short-circuit rings whose end faces are in contact with the copper strips, while filling the remaining space in the groove 3 with melt. After the aluminum melt has hardened, aluminum features 6 are formed in the remaining cross-sectional area inside the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com