Annealing apparatus

A technology of annealing device and furnace body, which is applied in the direction of lighting and heating equipment, furnace components, furnace types, etc., can solve the problems of short service life of the conveying device, and achieve the effect of long-term and long-term realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

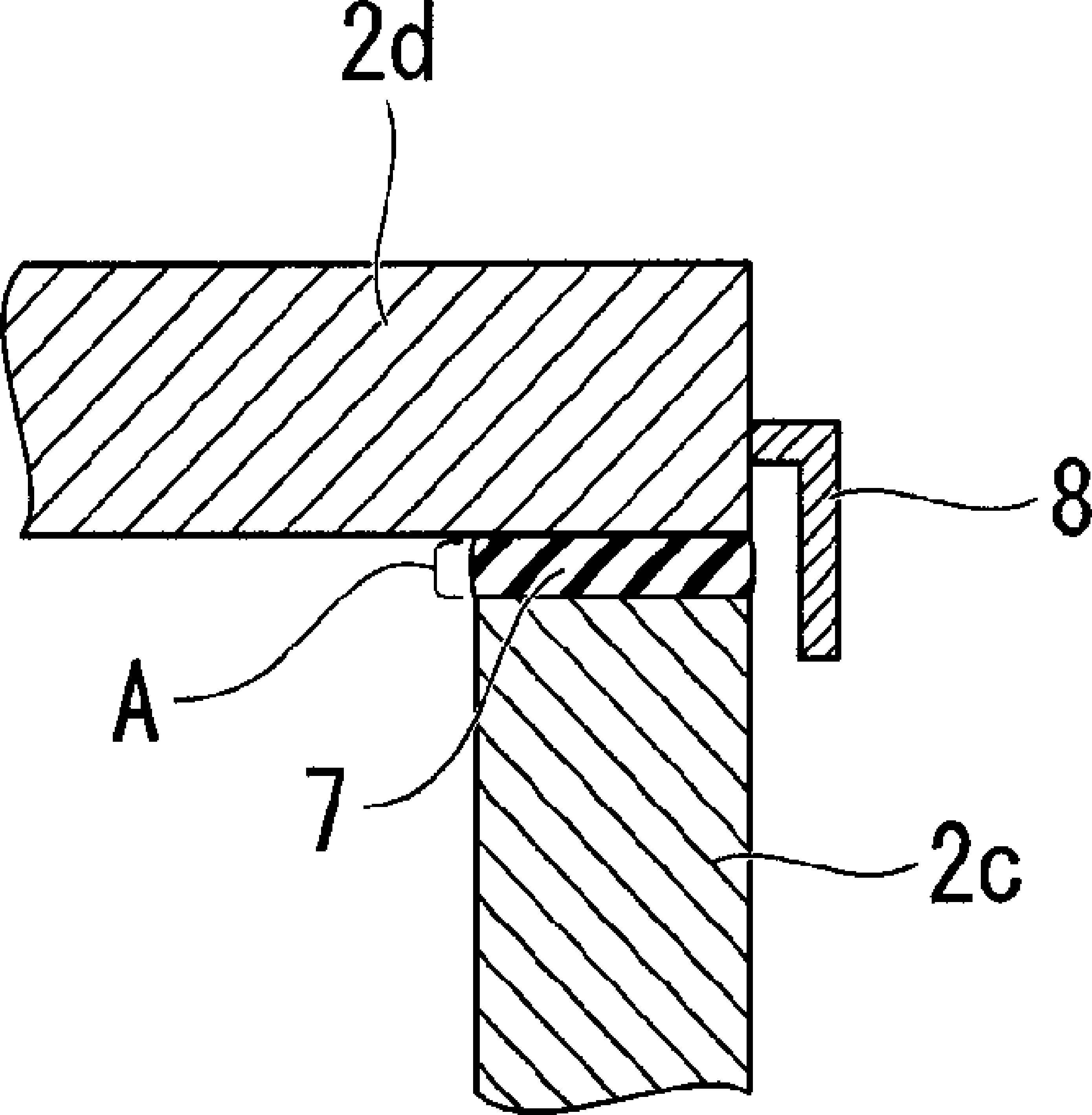

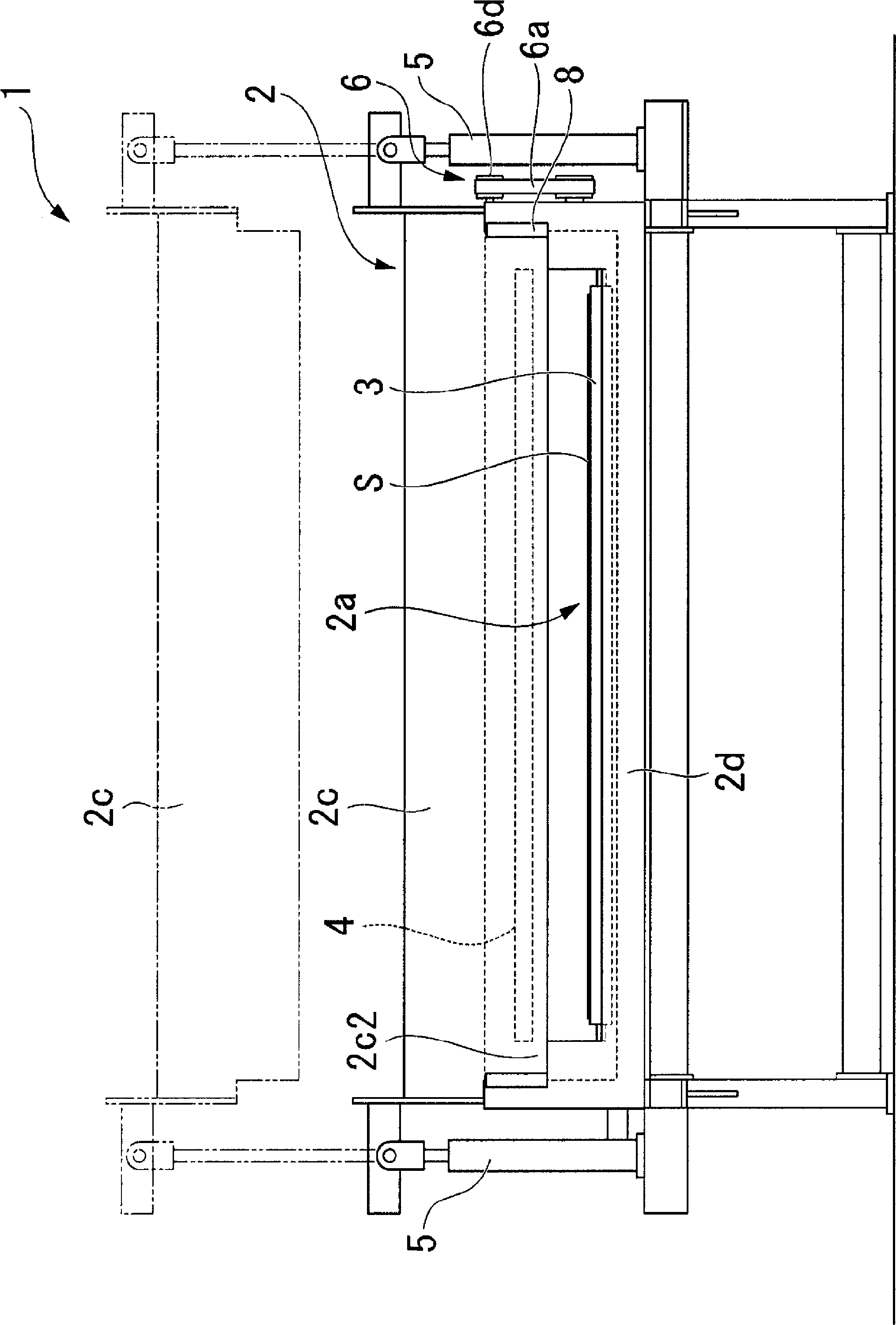

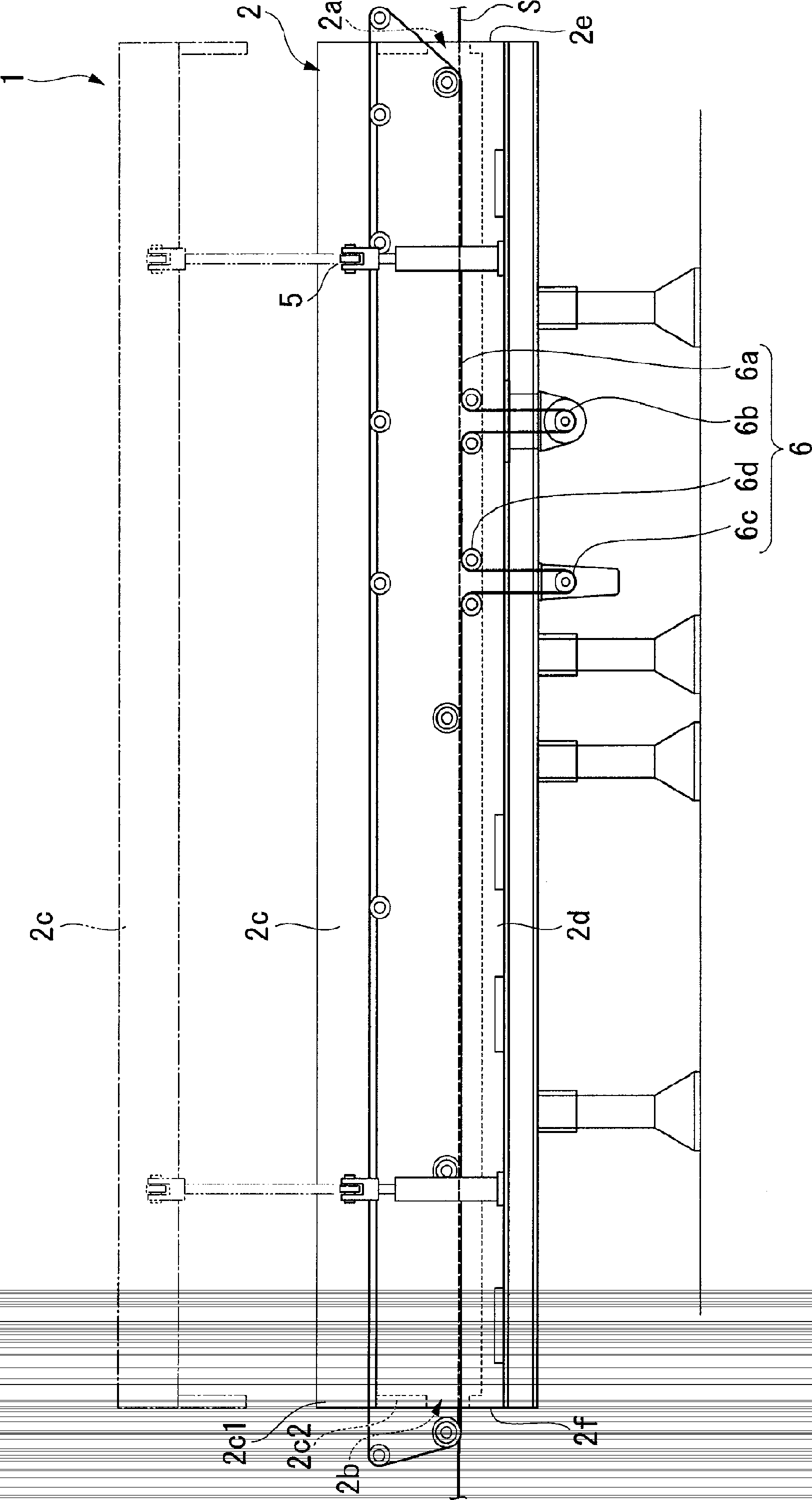

[0026] Below, refer to Figures 1 to 4 One embodiment of the annealing apparatus of the present invention will be described. In addition, in the following description, the scale of each member is changed suitably so that each member may be recognizable in size.

[0027] figure 1 as well as figure 2 is a schematic configuration diagram of the annealing apparatus 1 of the present embodiment, figure 1 is a side view of the annealing device 1, figure 2 is a front view of the annealing apparatus 1 .

[0028] As shown in these figures, the annealing apparatus 1 of this embodiment has the furnace body 2, the conveyance roll 3, the heater 4, the elevating device 5, and the conveyance device 6.

[0029] The sheet S is inserted into the interior of the furnace body 2 through the inlet opening 2a and the outlet opening 2b, and the sheet S is annealed therein. The furnace body 2 has a box shape extending along the conveying direction of the sheet S. As shown in FIG.

[0030] More...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com