Structure for reducing flashover length of moulded case circuit breaker

A molded case circuit breaker and arcing technology, applied in circuit breaker parts and other directions, can solve the problems of large arcing distance, arc short circuit, easy accident, etc., to improve safety performance, reduce arcing distance, and lengthen arc. The effect of moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

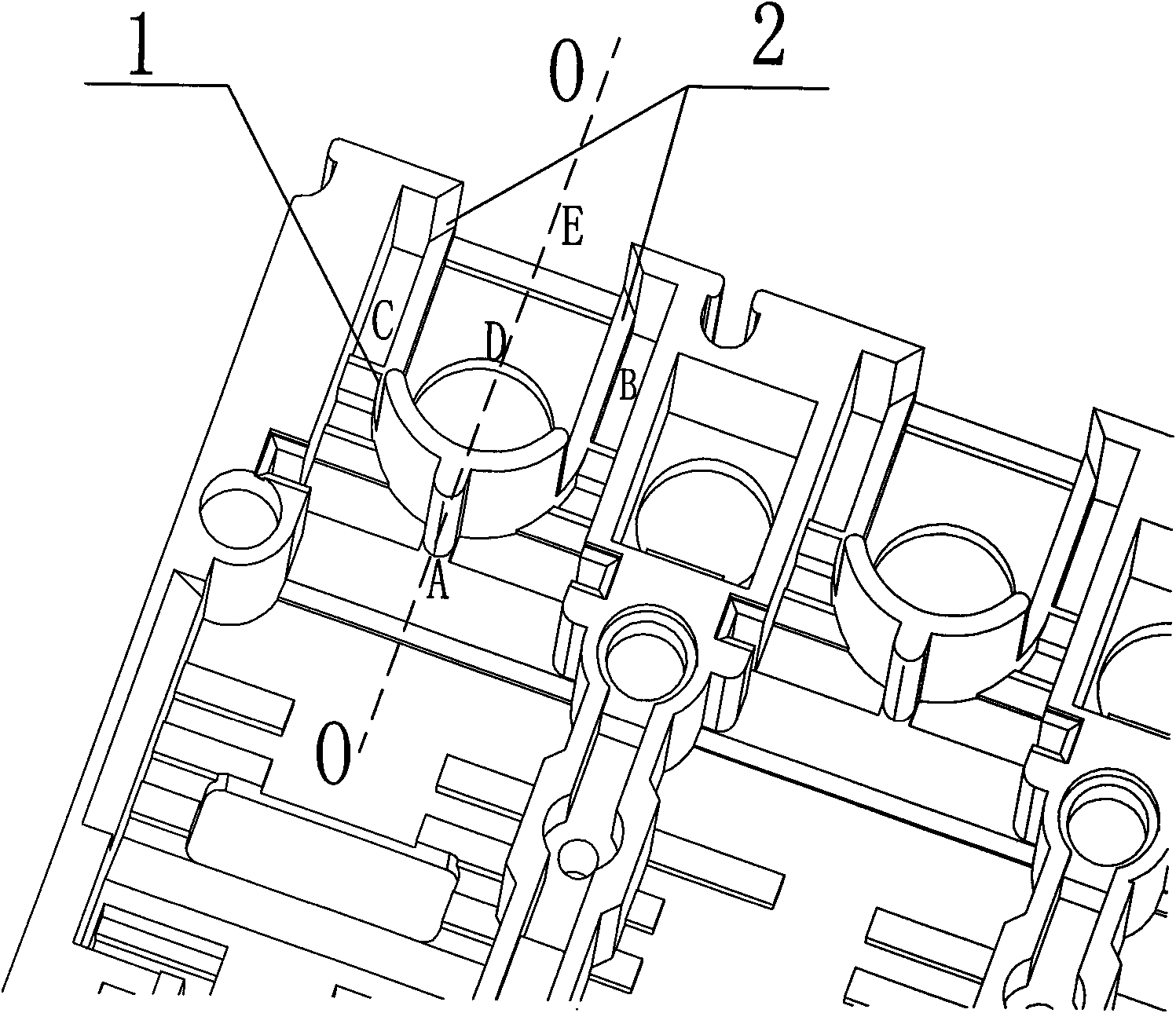

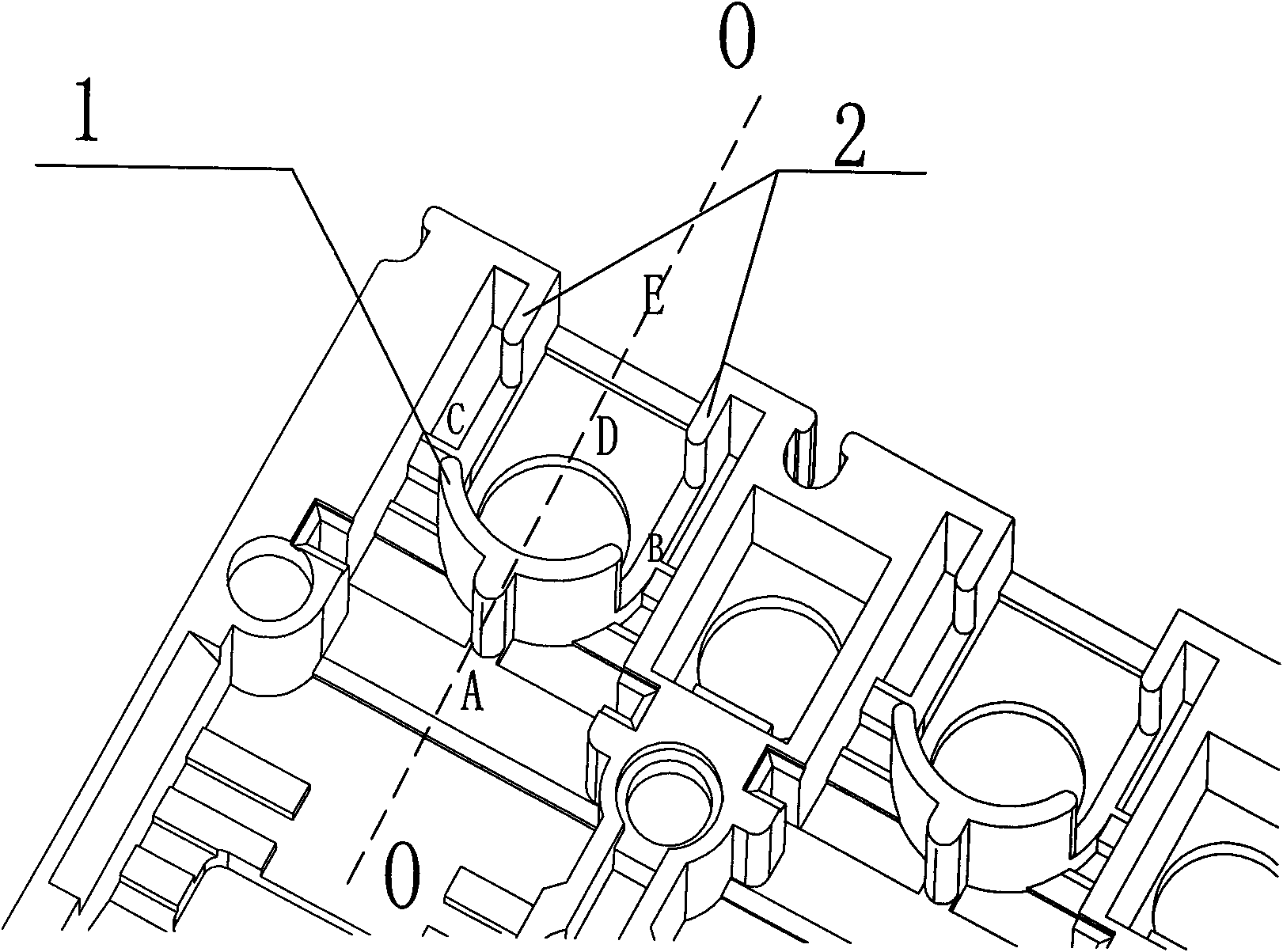

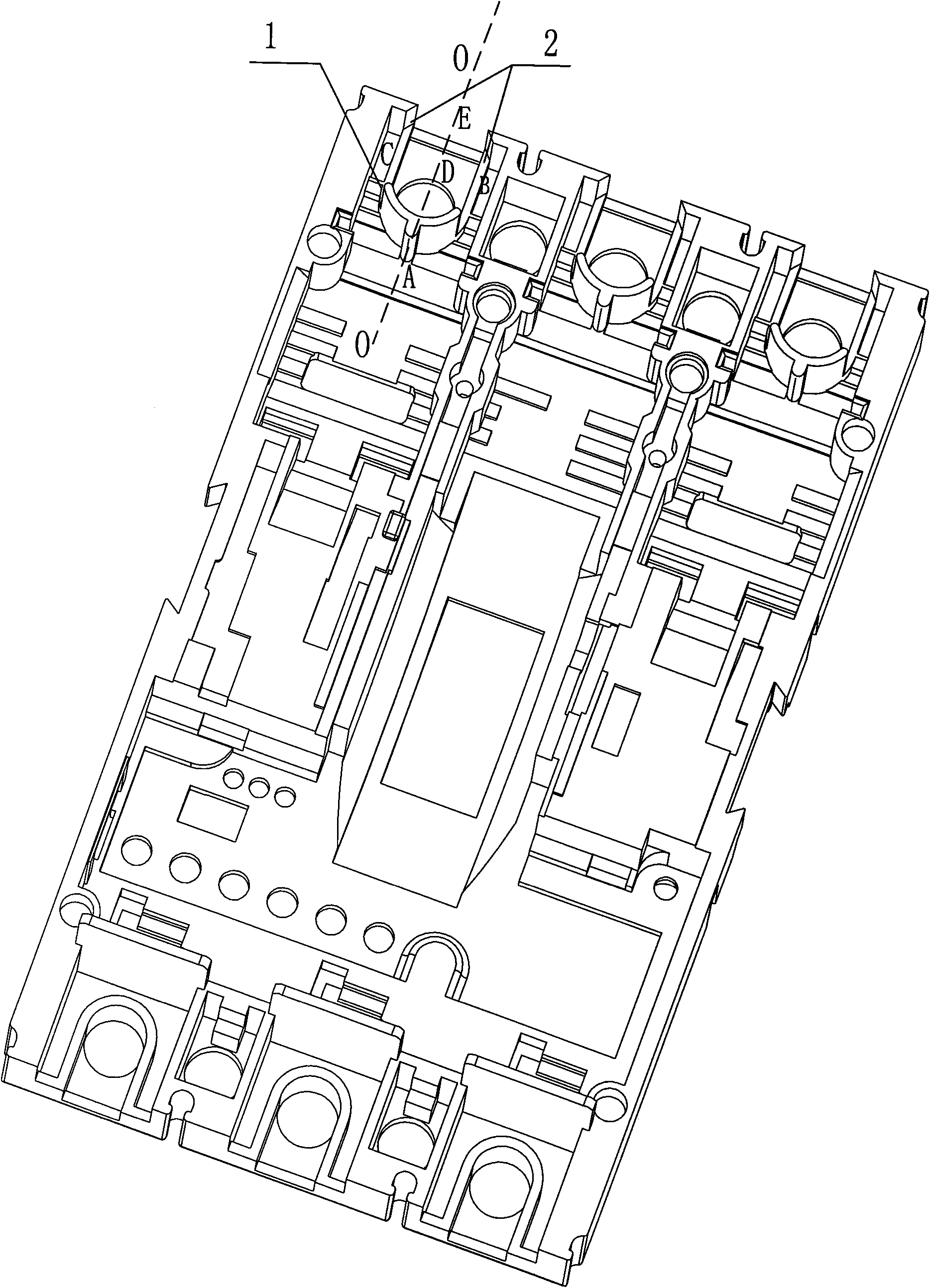

[0030] Such as figure 1 As shown, the large cover of the circuit breaker is provided with an arc-guiding wall structure 1 and an arc-retaining wall structure 2, and at least one of the arc-guiding wall structure and the arc-retaining wall structure corresponds to each electrode of the circuit breaker that needs arc protection.

[0031] The arc-guiding wall 1 is in the shape of an arc, and its arc top faces the direction of the electrode generating the arc. Two arc retaining walls 2 are located in front of both ends of the arc guiding wall 1 .

[0032] The arc retaining wall 2 is an inverted L-shaped wall structure extending forward from the sides of the arc guiding wall and folding inward at the end.

[0033] The inner and outer diameters of the arc guide wall 1 are determined according to the actual needs and the size of the internal structure. The arc retaining wall 2 is facing the O-O axis direction, and the projection of the arc guide wall 1 on a plane perpendicular to t...

Embodiment 2

[0037] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that the arc retaining wall 2 is an inverted U-shaped groove wall that extends forward from the side of the arc guide wall and folds inward at the end and then turns back for a section. body structure.

[0038] When the circuit breaks down and the circuit breaker breaks the problem circuit, a high-energy arc will be generated between the dynamic and static contacts, and the particles with high energy generated during the arc combustion process will be discharged outward. After the arc enters the large cover through the arc extinguishing chamber, it first touches the "arm on the A side of the arc guide wall" at point "A", and after the collision speed slows down, it is divided into two strands towards points "B" and "C". Arc, the arc passes through the "arc blocking wall" to change the direction of the arc, and the hedging collision gathers at the "D" point. At this time, a part of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com