System and method for simulating oil depot for oil and gas storage and transportation

A simulation system and oil depot technology, which is applied in the field of oil and gas storage and transportation oil depot simulation system, can solve the problems of lack of auxiliary means and methods, training on site, and difficulty in achieving the expected effect of training, so as to improve the training effect and reduce the training cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of the present invention is further described in detail below in conjunction with accompanying drawing:

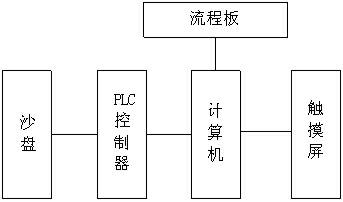

[0023] like figure 1 As shown, the oil and gas storage and transportation oil depot simulation system includes a sand table, a touch screen and a process board. There is a PLC controller under the sand table. The PLC controller is connected to the computer inside the sand table and the touch screen respectively, and the computer is connected to the external process board.

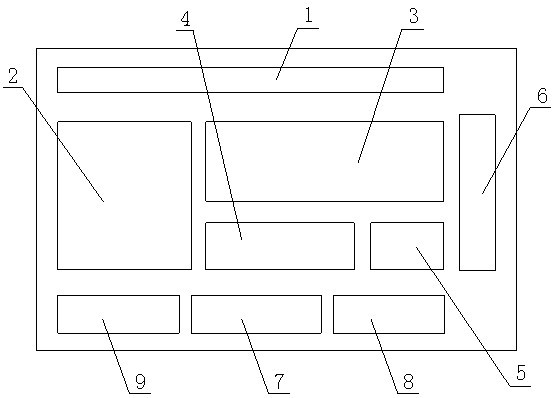

[0024] Oil and gas storage and transportation equipment and pipelines connecting the storage and transportation equipment are installed on the sand table. Control valves and LED light strips are installed in the import and export pipelines of the storage and transportation equipment, and the control valves and LED light strips are connected to the PLC controller.

[0025] like figure 2 As shown, there are train trestle 1, tank area 2, pump room area 3, fire pump area 4, mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com