Aqueous polyurethane dry process transform-film synthetic leather and manufacturing method thereof

A water-based polyurethane, dry film transfer technology, applied in chemical instruments and methods, synthetic resin layered products, textiles and papermaking, etc., to achieve the effect of plumpness and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

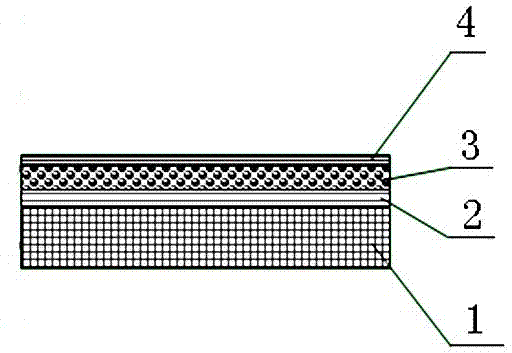

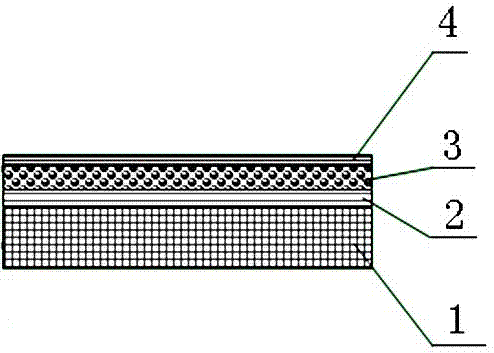

[0035] A water-based polyurethane dry-process transfer film synthetic leather, comprising a bottom layer 1, an adhesive layer 2, a foam layer 3, and a surface layer 4 connected sequentially from bottom to top, and the bottom layer 1 is a base fabric bottom layer with a non-woven fabric as a skeleton , The adhesive layer 2, the foam layer 3, and the surface layer 4 are all made of polyurethane materials.

[0036] A kind of manufacture method of water-based polyurethane dry transfer film synthetic leather, comprises following technological process:

[0037] Non-woven fabric as the base fabric of the skeleton Coating polyurethane surface layer, foam layer and adhesive layer on the release paper to realize dry film transfer Paper leather separation or leather paper separation after aging Inspection and warehousing

[0038] 1. Base fabric: choose high physical property base fabric to meet the physical property requirements of transfer film leather;

[0039] The base fabric...

Embodiment 2

[0056] The difference between the manufacturing method of a kind of water-based polyurethane dry transfer film synthetic leather of the present embodiment and embodiment 1 is:

[0057] The water-based polyurethane resin slurry system for the surface layer of the dry transfer film is prepared as follows: in parts by weight, 100 parts of water-based polyurethane resin, 10 parts of water-based color paste or 5 parts of pigment, 2 parts of peeling accelerator, 10 parts of leveling agent, defoaming 10 parts of agent, 10 parts of thickener, 10 parts of anti-sticking agent;

[0058] The water-based polyurethane slurry system for the foaming layer of the dry transfer film is formulated as follows: in parts by weight, 100 parts of water-based polyurethane resin, 15 parts of water-based color paste or 5 parts of pigment, and 10 parts of leveling agent;

[0059] The water-based polyurethane resin slurry system for the adhesive layer of the dry transfer film is formulated as follows: in p...

Embodiment 3

[0063] The difference between the manufacturing method of a kind of water-based polyurethane dry transfer film synthetic leather of the present embodiment and embodiment 1 is:

[0064] Base fabric: Non-stationary island (about 800 islands) nylon superfine fiber base fabric made of sea-island structure fibers impregnated with polyurethane resin and then decremented by toluene.

[0065] The water-based polyurethane resin slurry system for the surface layer of the dry transfer film is formulated as follows: in parts by weight, 100 parts of water-based polyurethane resin, 30 parts of pigment, and 10 parts of crosslinking agent;

[0066] The water-based polyurethane slurry system of the dry-process transfer film foaming layer is formulated as follows: in parts by weight, 100 parts of water-based polyurethane resin, 3 parts of pigment;

[0067] The water-based polyurethane resin slurry system for the dry transfer film adhesive layer is formulated as follows: according to parts by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com