Low hydrogen-oil ratio hydrotreating method and reactor

A hydrotreating and reactor technology, applied in the petroleum industry, refining hydrocarbon oil, etc., can solve the problems of inability to realize liquid-phase atomization, and achieve the effects of reducing daily operating costs, improving utilization efficiency, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] This example is an implementation of hydrocarbon oil hydrotreating, and the schematic diagram of the operation process refers to the figure 1 .

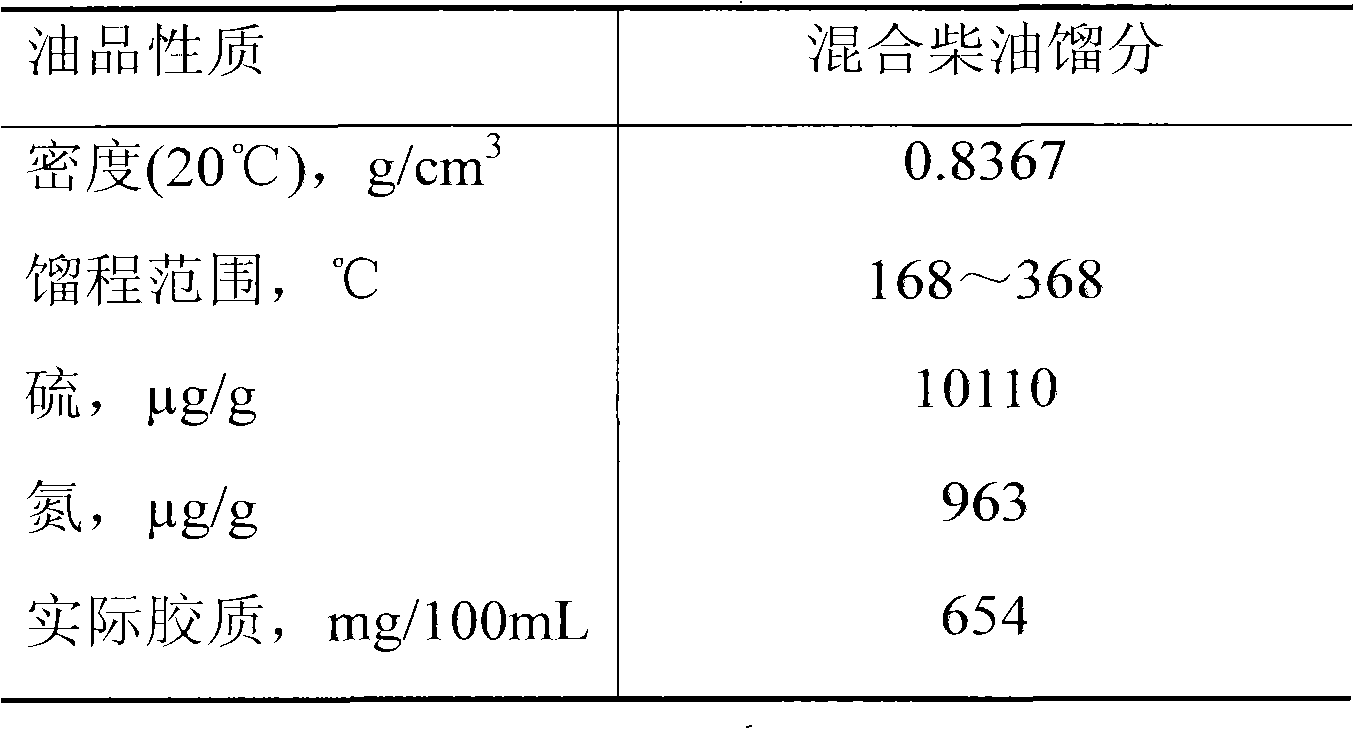

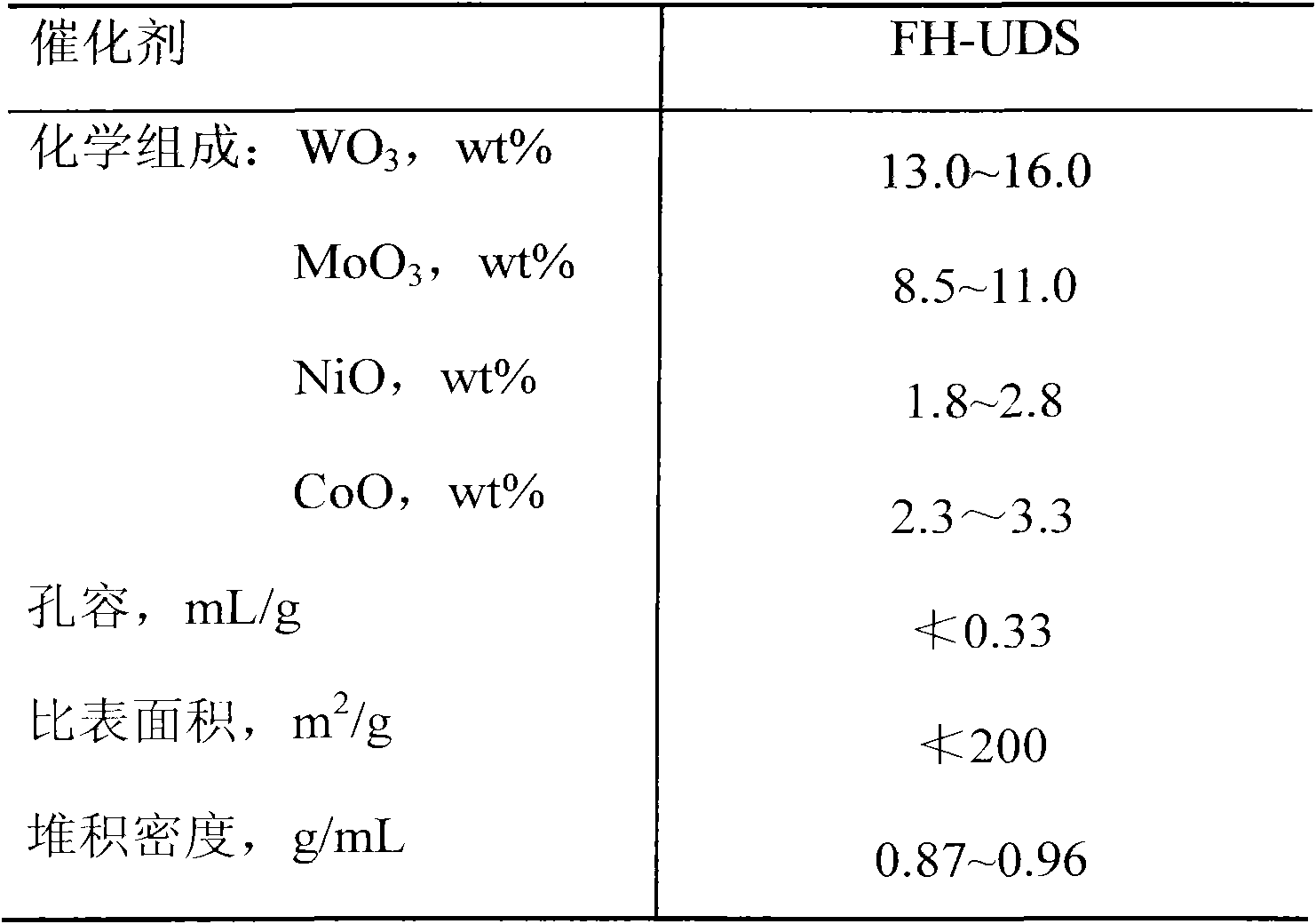

[0026] The properties of the raw oil used are shown in Table 1, and the catalyst is FH-UDS hydrotreating catalyst developed and produced by Fushun Petrochemical Research Institute. The composition and quality index of the FH-UDS catalyst are shown in Table 2, the process conditions are shown in Table 3, and the properties of refined diesel oil are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com