Technology for manufacturing brick by using dried sludge

A technology for making bricks and sludge from sludge, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. Excellent workability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

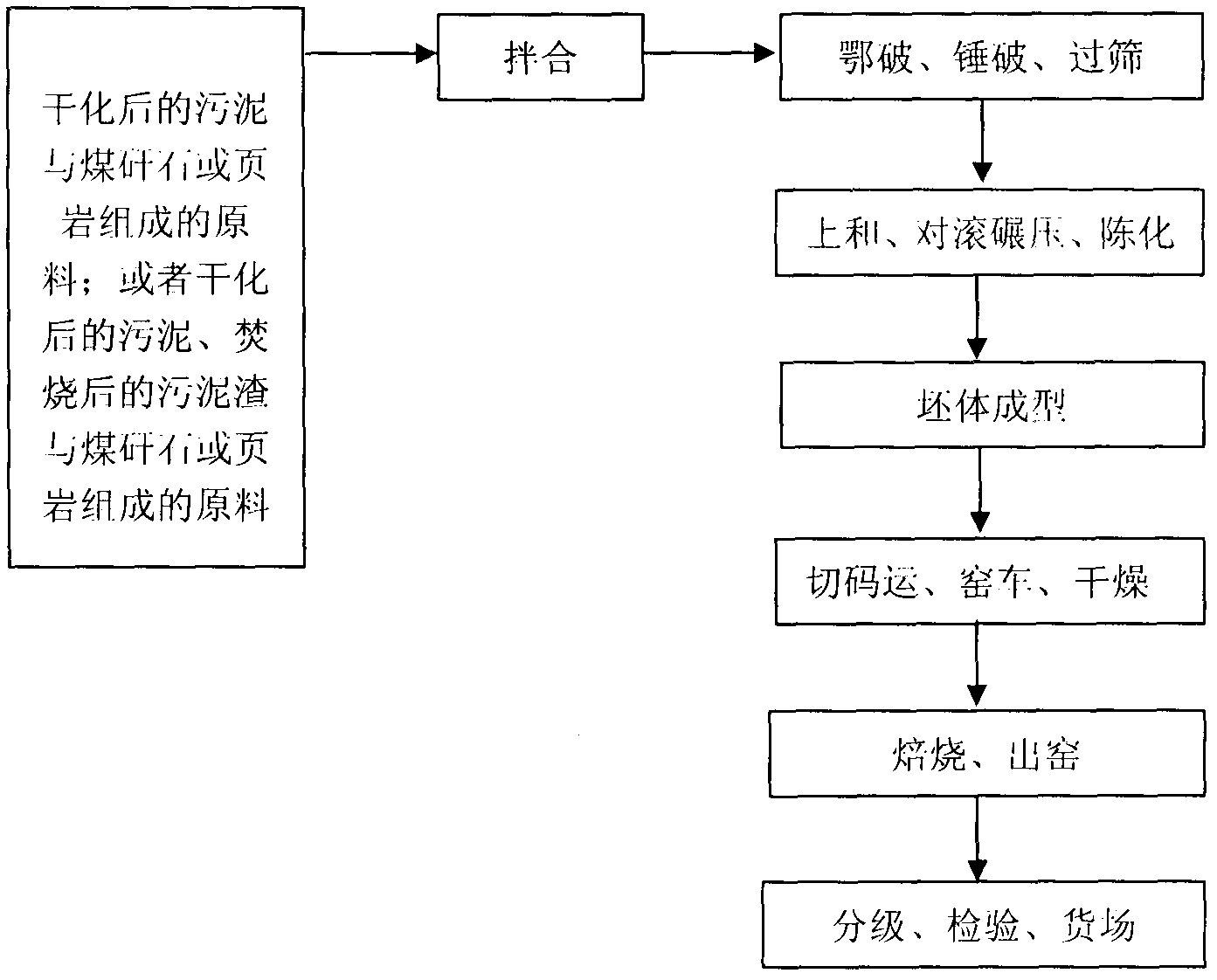

Method used

Image

Examples

Embodiment 1

[0025] Ingredients: According to the ratio of dried urban sludge: coal gangue = 30:70, the raw materials are mixed, and the particle size of the crushed material is required to be ≤5cm, the particle size of the hammered material is required to be ≤1cm, and the particle size of the sieve ≥6 mesh). Then enter the brick making process according to the ordinary brick making process.

[0026] Forming: control extrusion pressure ≥ 3.5MPa, vacuum degree ≥ 98%.

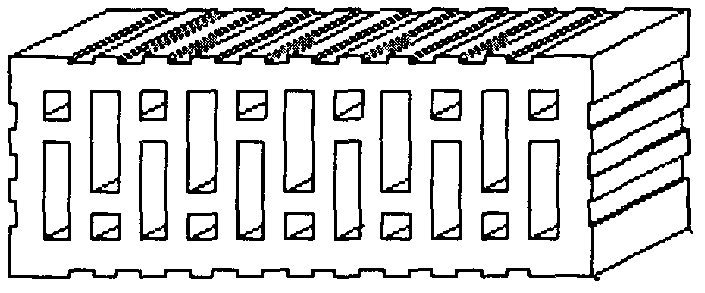

[0027] Sintering: sintering for 3 hours under the condition of controlling the maximum temperature of 1080 degrees to obtain microporous bricks (blocks), such as figure 2 shown.

[0028] After leaving the kiln, it is sorted and stored in the cargo yard. The appearance size is qualified, the brick strength is ≥ MU10 and the block is ≥ MU3.5, and it is qualified for freezing and fusion. The quality produced meets the relevant national standards (GB5101-2003, GB13544-2000, GB13545-2003 standards).

Embodiment 2

[0030] The specific process steps are the same as in Example 1, except that the ratio of raw materials is as follows: dried municipal sludge: shale: internal fuel = 35:60:5.

[0031] The sintering is controlled under the condition that the maximum temperature is 1050 degrees, and sintering is performed for 2.5 hours.

Embodiment 3

[0033] Concrete process step is identical with embodiment 1, and difference is that raw material ratio is as follows: sludge after drying: the urban sludge slag after incineration: coal gangue=20: 30: 50

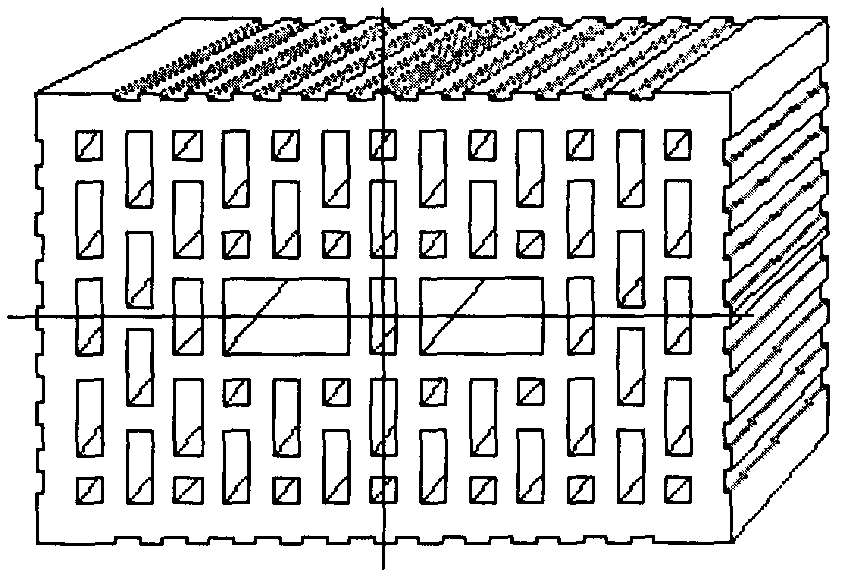

[0034] Under the condition of sintering control with a maximum temperature of 1100 degrees, sintering for 1.5 hours to obtain a microporous porous block, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com