Disc type aircraft

An aircraft and dish-type technology, applied in the field of aviation aircraft, can solve the problems of threatening the life and property safety of the crew, the limitation of helicopter activity space, and the high accident rate of helicopters, and achieve the effects of simple structure, convenient processing and manufacturing, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

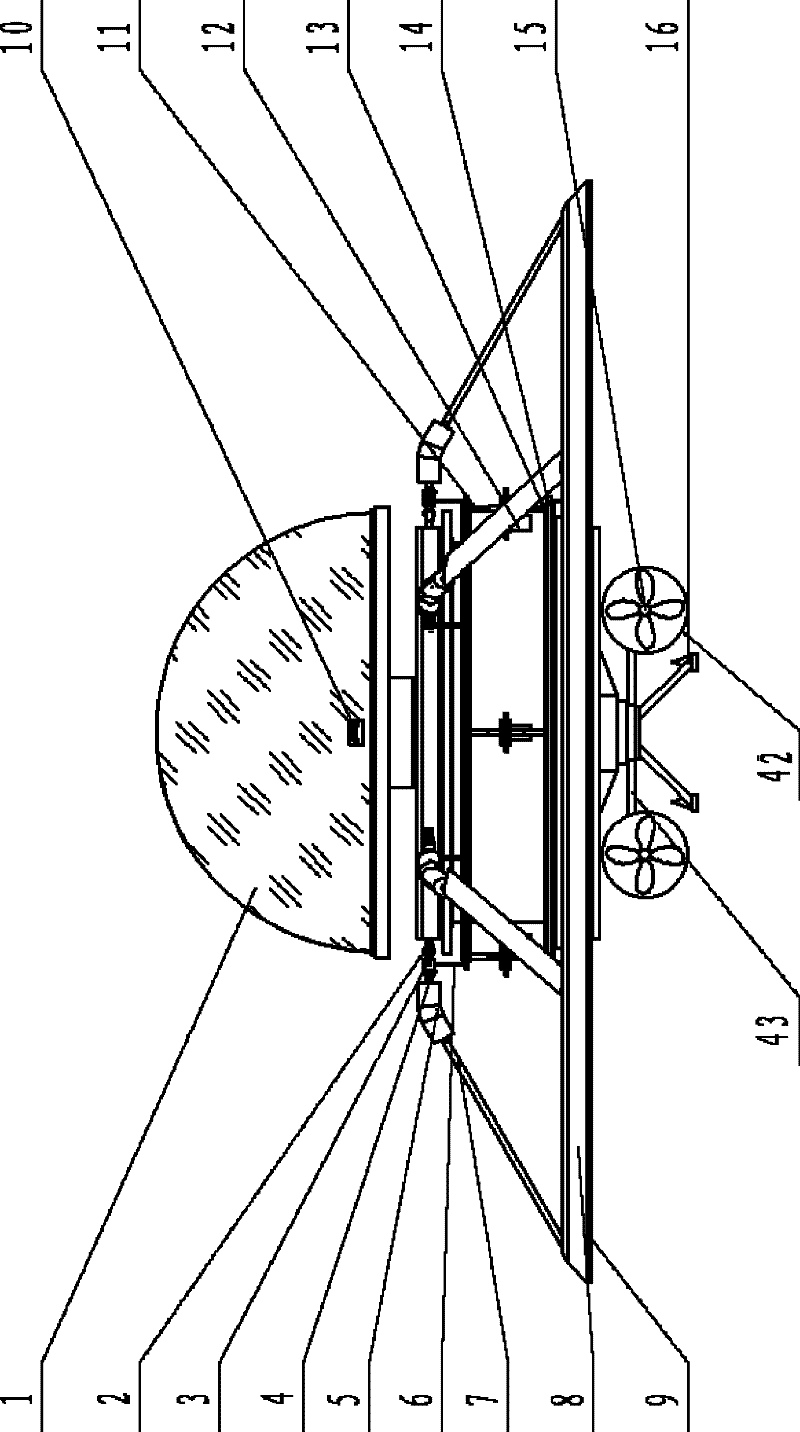

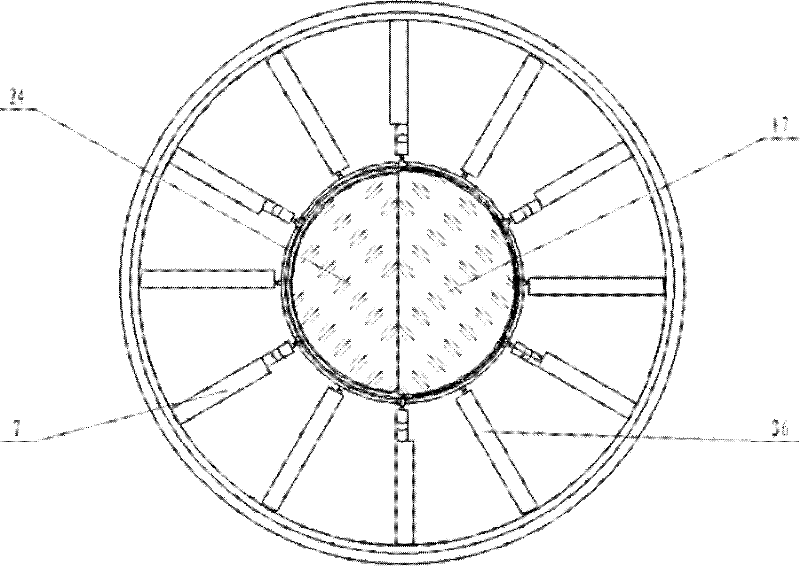

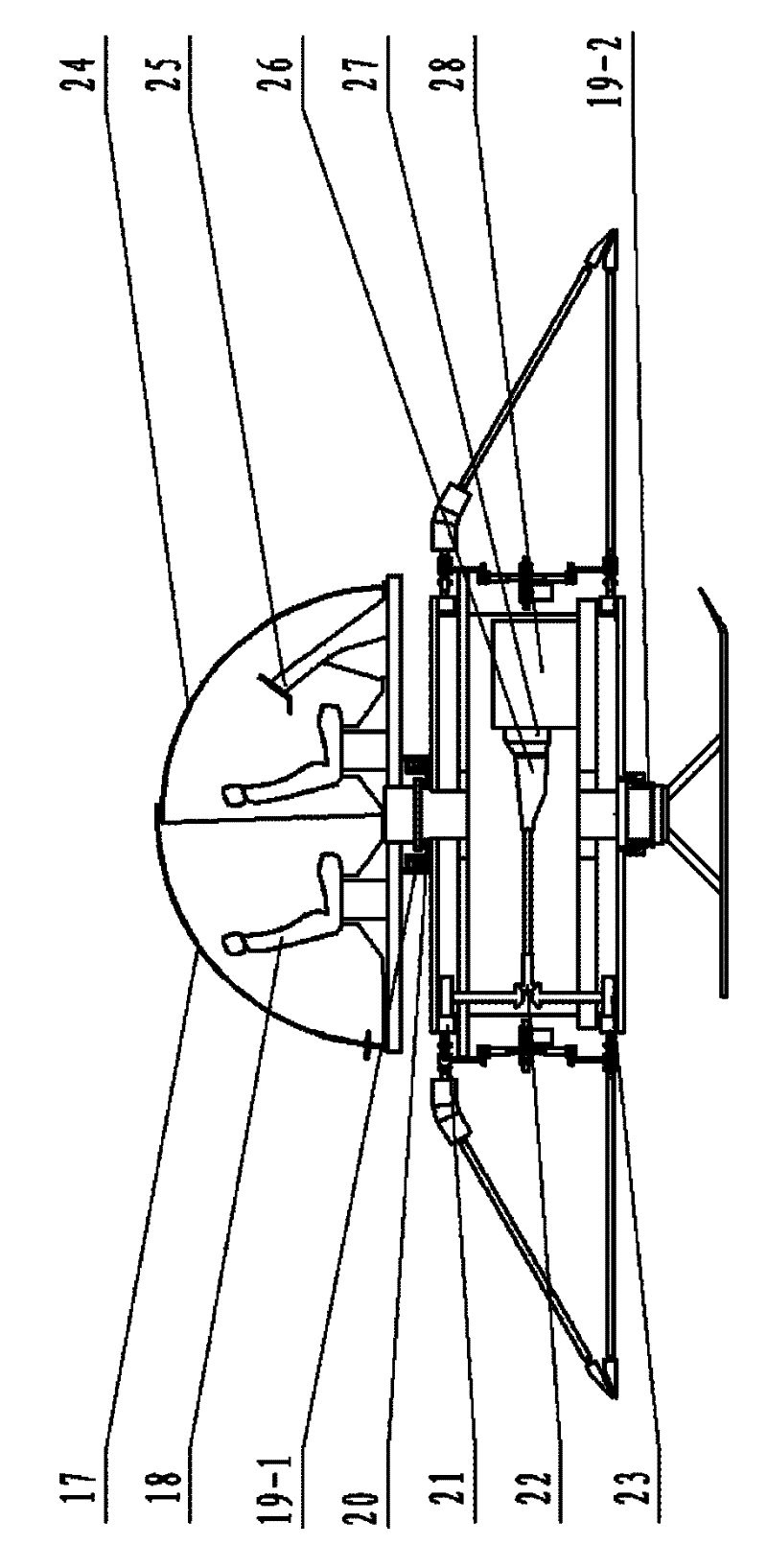

[0022] Such as figure 1 , figure 2 As shown, the saucer aircraft includes a cockpit 1, a fuselage, a torque conversion system, a rotor system, a transmission, a power system and a landing gear 16, and the fuselage is used as a fixed frame body of the overall structure of the aircraft, and the cockpit 1 is arranged on the fuselage top , the torque conversion system is driven by a servo motor 12, the servo motor 12 is connected to the gear transmission mechanism and the torque conversion hinge 4, one side of the torque conversion system is connected to the rotor system, and the rotor system is arranged on the outer edge of the fuselage, including the upper blade 7, the lower blade 36 and the propulsion paddle 15, the outer ends of the upper blade 7 and the lower blade 36 are respectively fixed by a fixed ring, the propulsion paddle 15 is arranged at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com