Structure of modular robot actuation system

A technology of drive unit and module structure, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as hindering robot movements, unsightly appearance, mechanical loss, etc., and achieve the effect of flexible movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

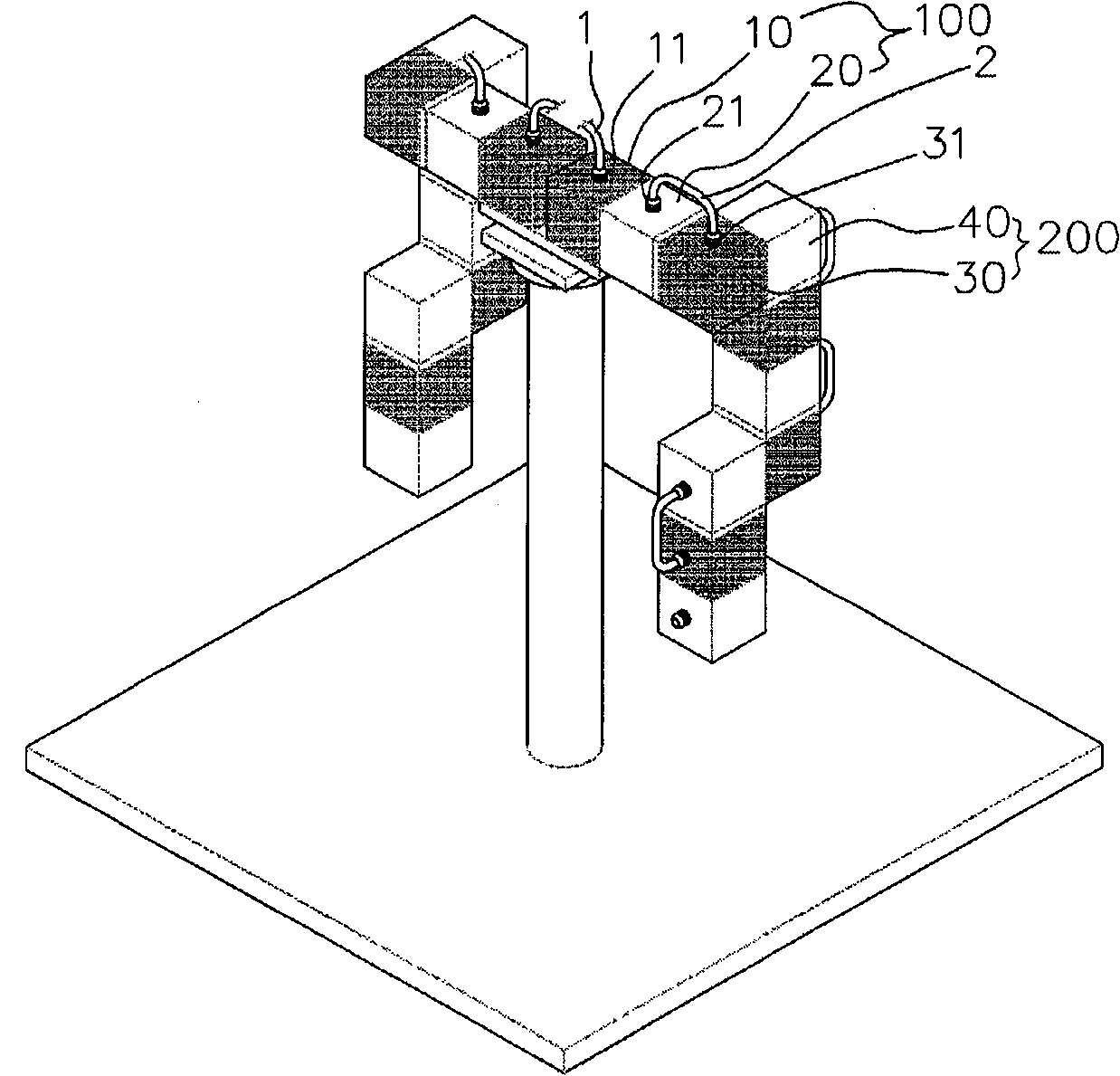

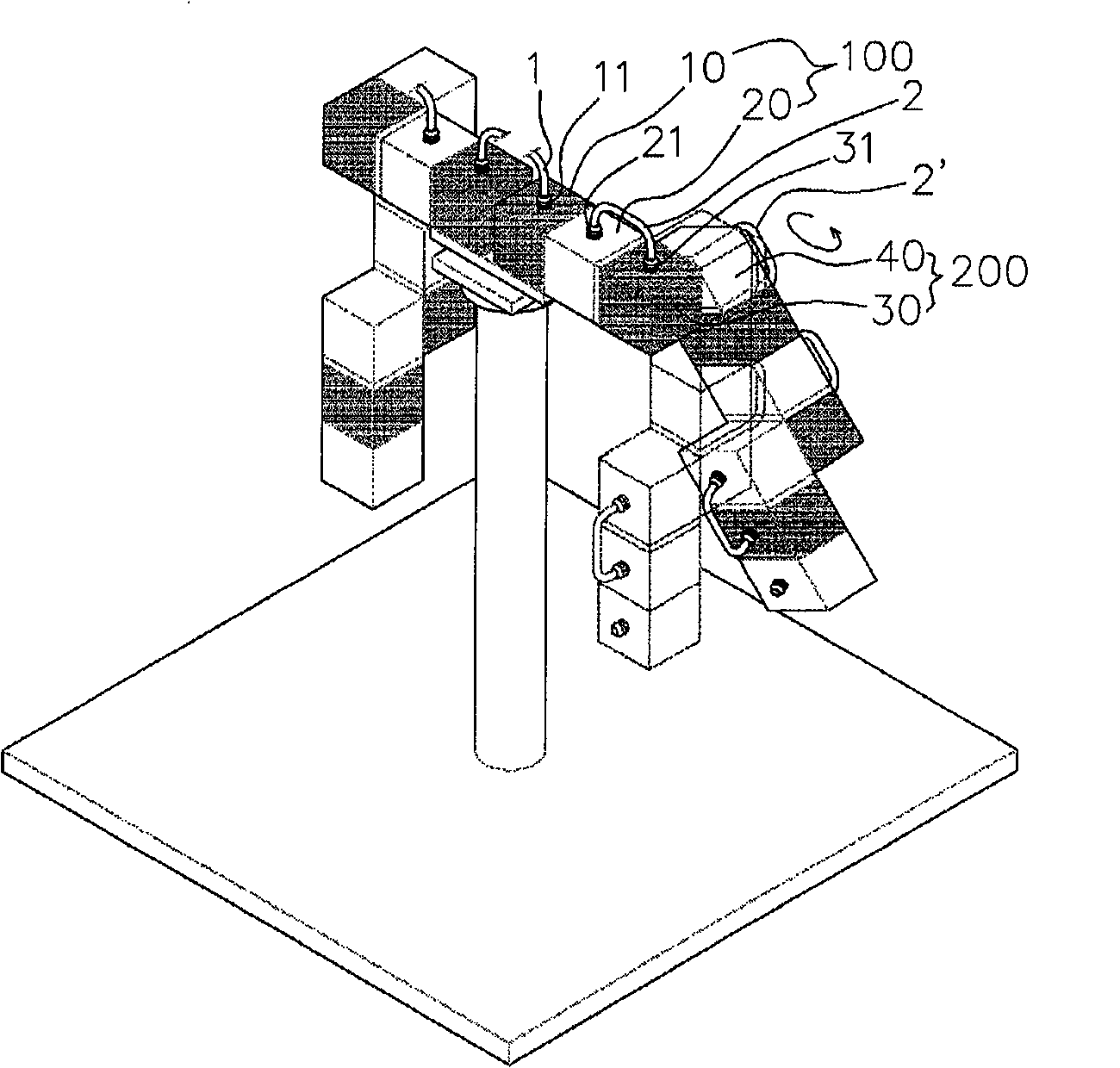

[0024] Hereinafter, preferred embodiments of the present invention will be described in further detail with reference to the accompanying drawings. When labeling the components in the drawings, the same reference signs are used as much as possible for the same components in different drawings. When describing the present invention, the detailed descriptions of related known functions or structures that may cause unnecessary confusion to the gist of the present invention are omitted. In addition, based on the principle that the inventor can properly define the terms and concepts in order to best describe his invention, the terms or words used in this specification and claims can only be used in accordance with the meaning and meaning of the technical idea of the present invention. concept explained.

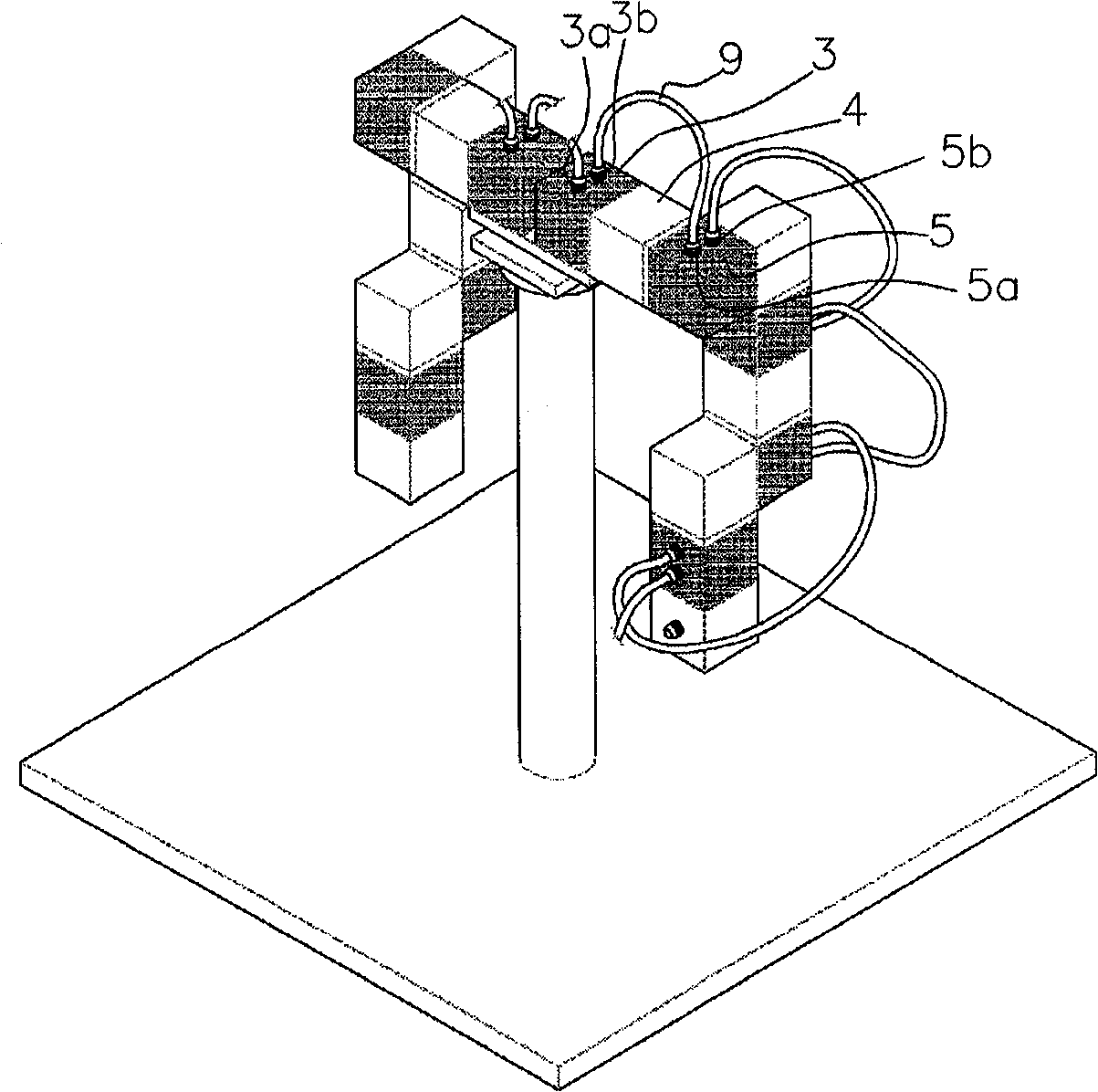

[0025] The invention relates to a module structure of a robot with more than two degrees of freedom. An input connector 11 and an output connector 21 to which cables 1 and 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com