A stator manufacturing process

A manufacturing process and stator technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, winding conductor shape/style/structure, etc., can solve the problem of poor assembly accuracy, easy to be affected by human factors, Difficult handling of connecting wires and other issues to achieve the effect of convenient maintenance and storage, simple connection and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The motor proposed by the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

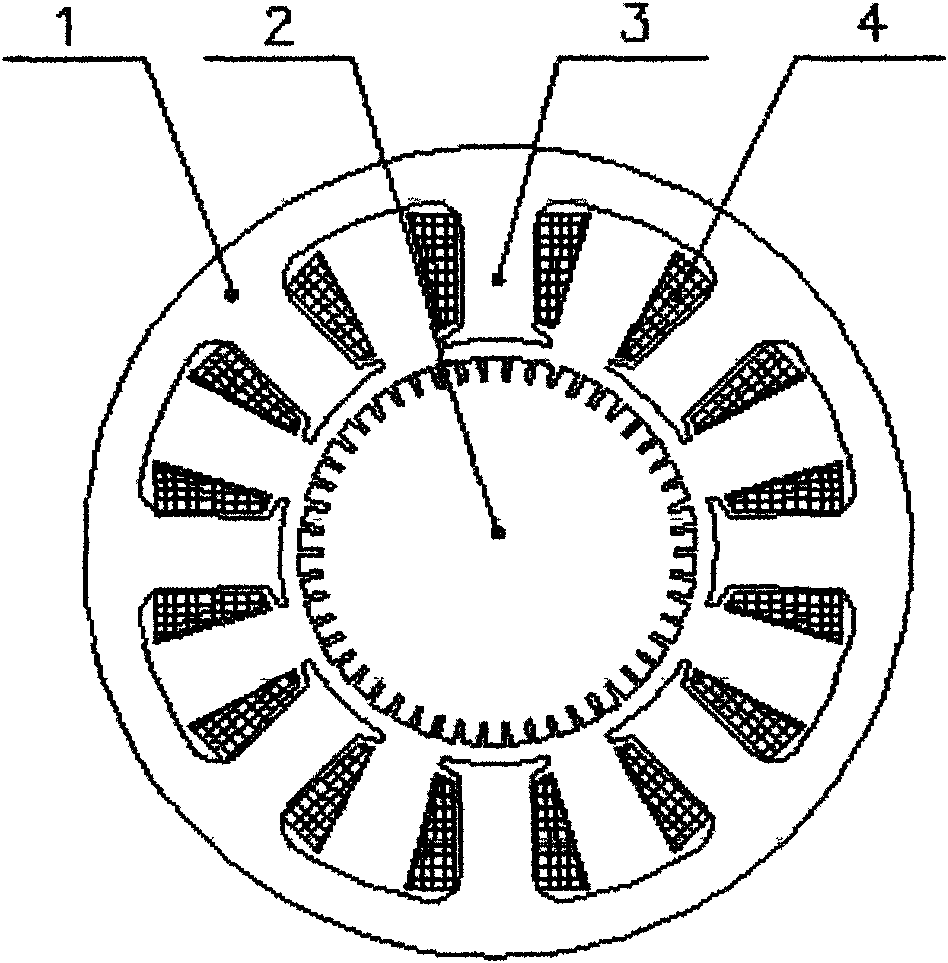

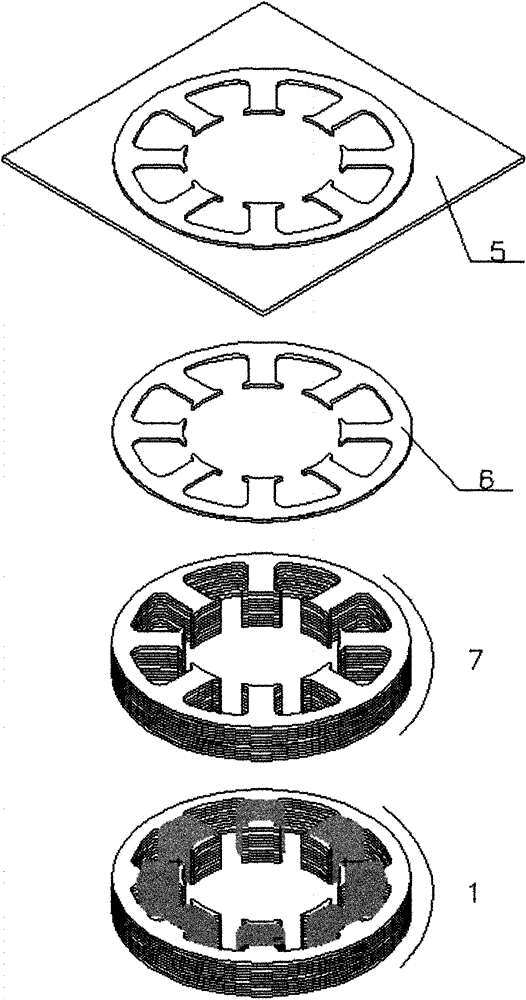

[0016] Fig. 10 is a perspective view of a preferred embodiment of a motor of the present invention, the motor stator includes an even number of iron cores 12 equally divided along the circumferential direction, coils 16 wound on the iron cores, and used to connect the iron cores The PCB board 18 of the coil tail and the casing 20 with an open slot 21 .

[0017] Concave-convex dots 10 are respectively provided on the stator punches that make up the iron core 12 to ensure the precise fit between the stator punches 9 when stacking the sheets; The coils 16 arranged trapezoidally in the direction of the inner circumference of the magnetic pole teeth toward the stator direction, as shown in Figure 8; a circuit is arranged on the PCB board 18 for connecting the tail wires produced by the individual winding of each iron core 12; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com